A double-sweep waverider

A waverider and layout technology, which is applied in the field of aerodynamic design of hypersonic vehicles, can solve the problems of poor low-speed performance and poor longitudinal stability of waveriders, and achieve enhanced longitudinal stability, flexible design methods, and improved aerodynamic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

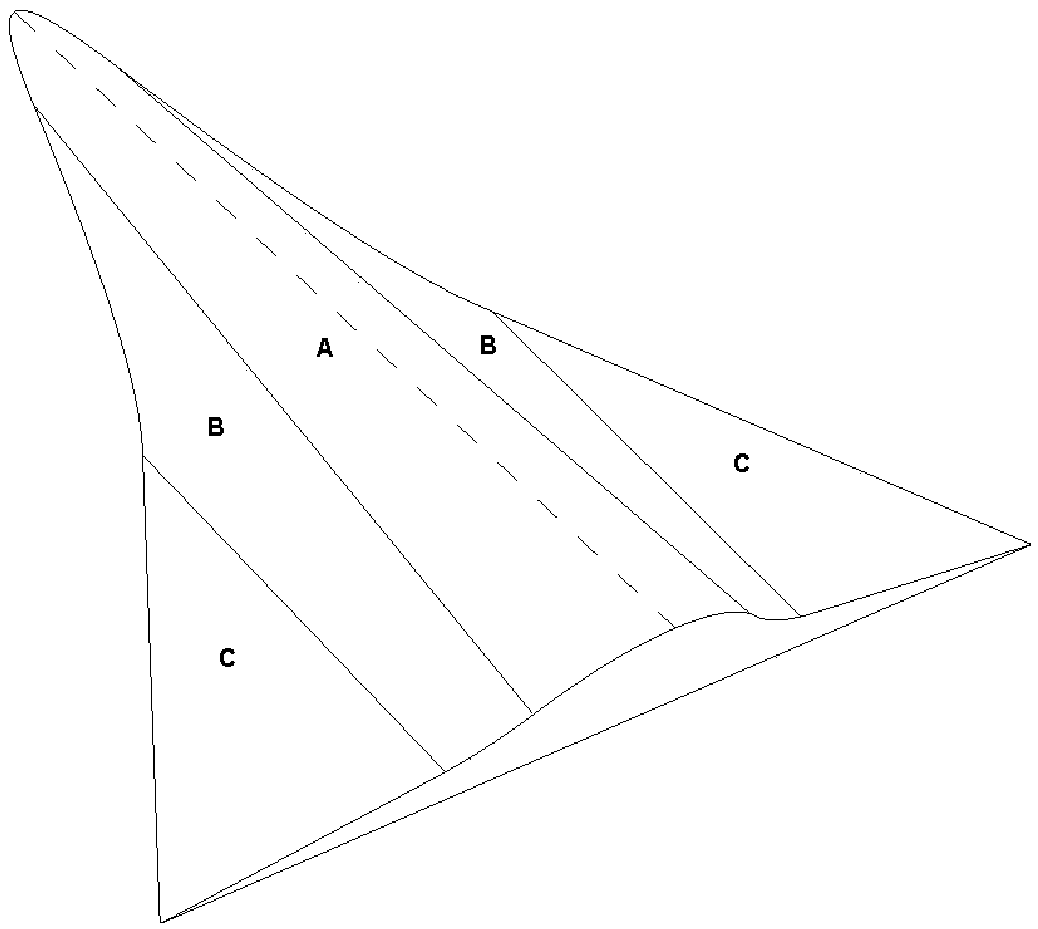

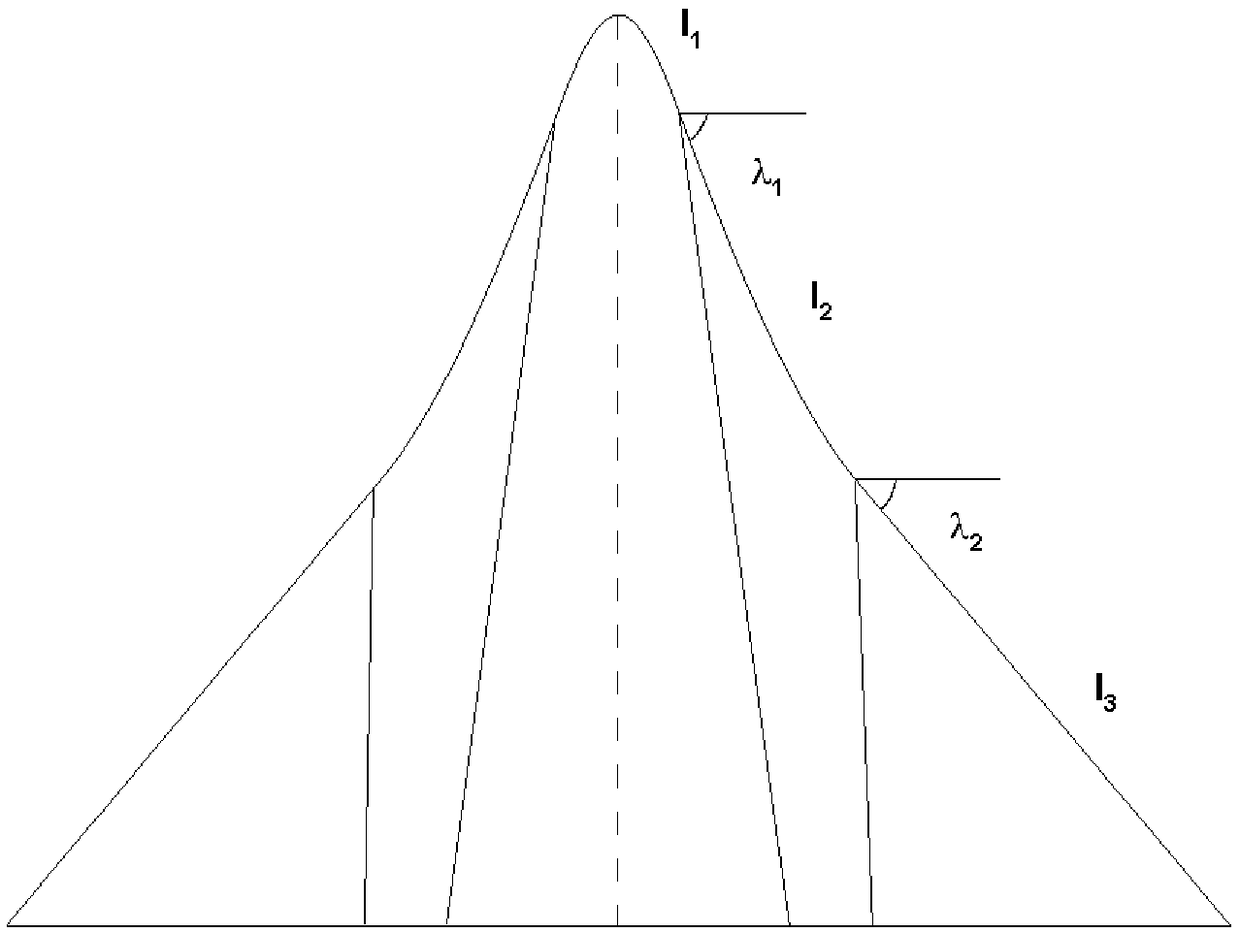

[0026] Design principle of the present invention: separately design the waverider parts with different characteristics, and combine them to obtain the double-sweep characteristic waverider layout form, including the blunt head area, the large-sweep angle area and the small-sweep angle area, such as figure 1 A, B, C areas in. figure 2 The planar shape diagram is given, where l 1 , l 2 , l 3 are the leading edge lines of the above three regions, λ 1 and lambda 2 are the sweep angles of the large and small sweep angle regions, respectively. This shape waverider has advantages in low-speed state performance and longitudinal stability. The blunt region can be obtained by the cone guide or the close cone method, and the other regions are all obtained by the close cone method.

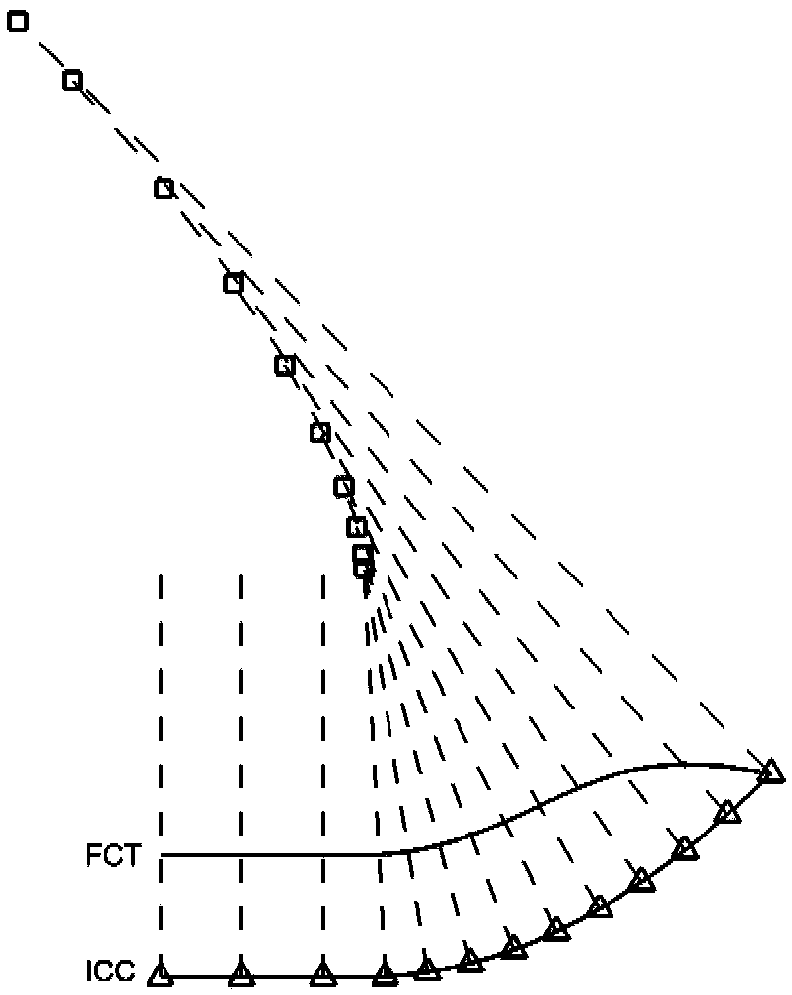

[0027] Briefly introduce the design principle of close cone waveriders, such as image 3 As shown, the ICC curve is used as the exit profile of the shock wave, and a point is drawn on the ICC curve as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com