A kind of in-situ regeneration method of PD catalyst for CO dehydrogenation purification

An in-situ regeneration and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of increasing regeneration costs and achieve in-situ regeneration , good regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the CO gas dehydrogenation reactor, N 2 Pass it into the reaction tube containing the deactivated catalyst and purge for 12h at 100℃, N 2 The airspeed is 1000h -1 ; Raise the reaction temperature to 700°C and pass O 2 With N 2 The mixed gas is oxidized for 12h, and the space velocity of the mixed gas is 1000h -1 , O 2 The content is 50%; after the oxidation treatment, at this temperature, pass in HCl and N 2 The mixed gas is chlorinated for 5h, and the space velocity of the mixed gas is 1000h -1 , The content of HCl gas is 5%; after the chlorination treatment, the reaction device is cooled to 400°C, and H 2 With N 2 The mixed gas is reduced for 5h, and the space velocity of the mixed gas is 1000h -1 , H 2 The content is 50%; after the reduction is completed, pass into N 2 Lower the reaction device to room temperature, N 2 Airspeed is 1000h -1 , Complete regeneration.

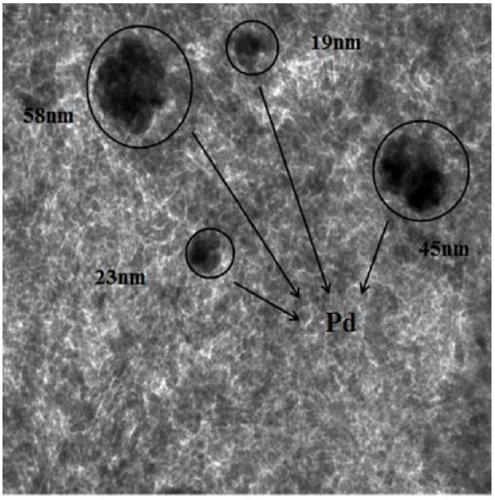

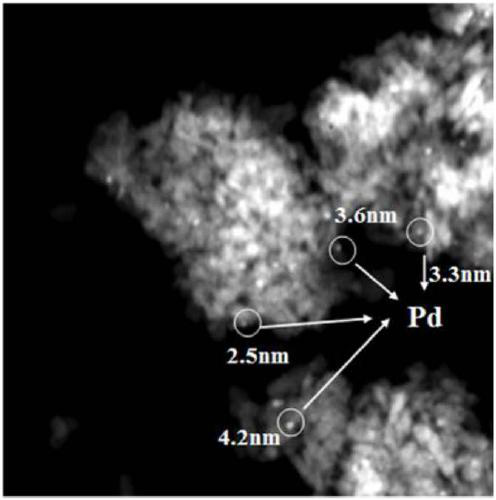

[0025] The performance evaluation of the regenerated catalyst, the residual H after the reaction 2 The co...

Embodiment 2

[0027] The regeneration process is the same as in Example 1, except that the inert gas He replaces N in the process. 2 Processing 3h, the airspeed of He is 500h -1 ; The oxidation conditions are: T=200℃, the space velocity is 100h -1 Pure O 2 Oxidation treatment is 1h instead of T=700℃, the space velocity is 1000h -1 O 2 The mixed gas with a content of 50% is treated for 12 hours.

[0028] The performance evaluation of the regenerated catalyst, the residual H after the reaction 2 The content is 32 ppm and the selectivity is 69.8%. Through static CO chemisorption detection, the Pd dispersion of the regenerated catalyst was 40.5%, and the average Pd particle size was 2.5 nm.

Embodiment 3

[0030] Same as the regeneration process of Example 1, the difference is that the inert gas Ar replaces N in the process 2 ; The chlorination condition is: the space velocity is 100h -1 HCl content of 10% mixed gas chlorination treatment 1h instead of 1000h space velocity -1 The mixed gas with HCl content of 5% is chlorinated for 5h.

[0031] The performance evaluation of the regenerated catalyst, the residual H after the reaction 2 The content is 76 ppm and the selectivity is 63.7%. Through static CO chemical adsorption detection, the Pd dispersion of the regenerated catalyst was 25.7%, and the average Pd particle size was 4.1 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com