Preparation method of bismuth vanadate/strontium titanate composite photocatalyst

A technology of catalyst and composite light, which is applied in the field of composite materials and clean energy, and can solve the problems of low migration rate of photogenerated carriers, inability of catalyst to produce hydrogen, and narrow bandgap width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

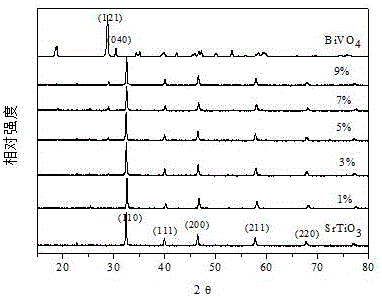

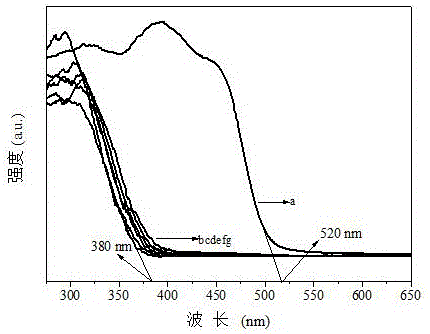

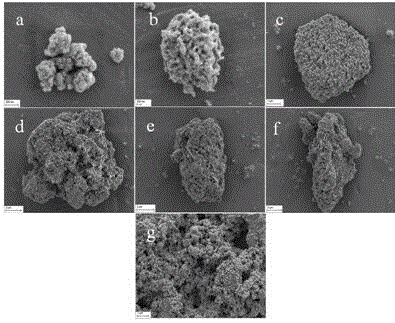

Method used

Image

Examples

Embodiment 1

[0033] 1) BiVO 4 preparation of

[0034] 2.425g Bi(NO 3 ) 3 ·5H 2 O was added with 25 mL of diluted 10% (w / w) HNO 3 In the solution, magnetically stir for 15-20min, add 2.104g citric acid monohydrate, and continue to stir to obtain a uniform and stable white solution, which is designated as solution A;

[0035] 0.5845g NH 4 VO 3 Dissolve in 20mL of distilled water at 90°C, place in a constant temperature water bath at 80°C and stir for 15 minutes, then add 2.104g of citric acid monohydrate, and continue stirring until a uniform and stable dark blue solution is obtained, which is designated as solution B; Add liquid A, the color of the solution gradually deepens, and finally turns dark green, which is recorded as solution C; adjust the pH of solution C to 6.5 with ammonia water, then place it in a constant temperature water bath at 80°C and continue stirring, and take it out after forming a dark blue gel Transfer to a drying oven at 70°C and dry for 12 hours; finally, af...

Embodiment 2

[0041] (1) BiVO 4 The preparation: with embodiment 1;

[0042] (2) SrTiO 3 The preparation: with embodiment 1;

[0043] (3) BiVO 4 / SrTiO 3 Preparation of Composite Photocatalyst

[0044] Accurately weigh 0.015g BiVO 4 Added to 30mL distilled water, stirred at room temperature for 15min, ultrasonicated for 15min; then added 0.485g SrTiO 3 , stirred for 15 min, ultrasonicated for 15 min, evaporated to dryness in a constant temperature water bath at 60 °C (about 3 h), and then transferred to a muffle furnace for calcination at 500 °C for 2 h to prepare BiVO 4 / SrTiO 3 composite photocatalyst. BiVO in sample 4 The mass percentage content is 3%. The catalyst is used in the photocatalytic water splitting hydrogen production process, and the hydrogen production reaches 329.5 μmol / g.

Embodiment 3

[0046] (1) BiVO 4 The preparation: with embodiment 1;

[0047] (2) SrTiO 3 The preparation: with embodiment 1;

[0048] (3) BiVO 4 / SrTiO 3 Preparation of Composite Photocatalyst

[0049] Accurately weigh 0.025g BiVO 4 Add to 30mL distilled water, stir at room temperature for 15min, ultrasonic for 15min; then add 0.475g SrTiO 3 , stirred for 15 min, ultrasonicated for 15 min, evaporated to dryness in a constant temperature water bath at 60 °C (about 3 h), and then transferred to a muffle furnace for calcination at 500 °C for 2 h to prepare BiVO 4 / SrTiO 3 composite photocatalyst. BiVO in sample 4 The mass percentage content is 5%. The catalyst is used in the photocatalytic water splitting hydrogen production process, and the hydrogen production reaches 611.6 μmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com