Disposable wetting nasal oxygen cannula

A nasal oxygen tube, a disposable technology, applied in the field of medical equipment, can solve the problems of inconvenient operation, large space occupied, and loud humidification bubble bath, etc., and achieve the effect of convenient operation, small size and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

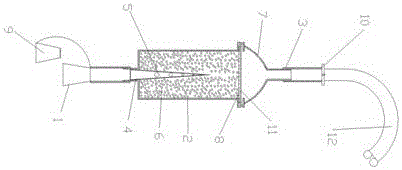

[0026] A disposable humidifying nasal oxygen tube, including an air inlet 1, a humidifying tube 2, an air outlet 3, and a bottom cover 7 of the humidifying tube. At the upper end, the air outlet 3 is located on the bottom cover 7 of the humidification tube. The humidification tube 2 is equipped with a solid humidification substance 6 water-absorbing resin. The humidification tube 2 is equipped with an air guide tube 4. The air guide tube 4 is inserted into the humidification tube from the air inlet 1 2, air duct 4 is distributed with ventilation holes 5, and the size of the ventilation holes is uniform up and down. There is a filter membrane 8 between the bottom cover of the humidification tube 7 and the humidification tube 2. 0.22μM, between the filter membrane 8 and the humidification tube 2 there is a mesh pressing piece 11, the mesh pressing piece 11 is convex, the air guide tube 4 is tapered, the lower end is sealed, and the air inlet 1 is equipped with a plug The plug 9 ...

Embodiment 2

[0030] A disposable humidifying nasal oxygen tube, comprising an air inlet 1, a humidifying tube 2, an air outlet 3, and a bottom cover of the humidifying tube 7, the solid humidifying substance 6 is a water-absorbing gel, and the air inlet 1 is located in the humidifying tube 2, the air outlet 3 is located on the bottom cover 7 of the humidification tube, the humidification tube 2 is equipped with a solid humidification substance 6 water-absorbing gel, the humidification tube 2 is equipped with an air guide tube 4, and the air guide tube 4 is inserted into the humidification tube Inside the humidification tube 2, there are vent holes 5 distributed on the air guide tube 4, the vent holes are large at the top and small at the bottom, and there is a filter membrane 8 between the bottom cover 7 of the humidification tube and the humidification tube 2, and the filter membrane 8 is polytetrafluoroethylene single-sided Attached filter membrane with a pore size of 0.45 μM. There is a ...

Embodiment 3

[0034] A disposable humidifying nasal oxygen tube, comprising an air inlet 1, a humidifying tube 2, an air outlet 3, and a bottom cover of the humidifying tube 7, the solid humidifying substance 6 is a water-absorbing gel, and the air inlet 1 is located in the humidifying tube 2 The upper end, the air outlet 3 is located on the bottom cover 7 of the humidification tube, the humidification tube 2 is equipped with a solid humidification substance 6 water-absorbent gel and water-absorbent resin, the humidification tube 2 is equipped with an air guide tube 4, and the air guide tube 4 is connected from the air inlet 1. Insert it into the humidification tube 2. There are vent holes 5 distributed on the air guide tube 4. The top of the vent hole is large and the bottom is small. There is a filter membrane 8 between the humidification tube bottom cover 7 and the humidification tube 2. The filter membrane 8 is polytetrafluoroethylene Ethylene single-sided film-attached filter membrane w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com