A kind of cold fresh pork nano fresh-keeping agent and its preparation method and fresh-keeping method

A preservative and nanotechnology, applied in the field of preparation technology of natural preservatives, can solve problems such as lack of technology, and achieve the effects of abundant resources, simple processing equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

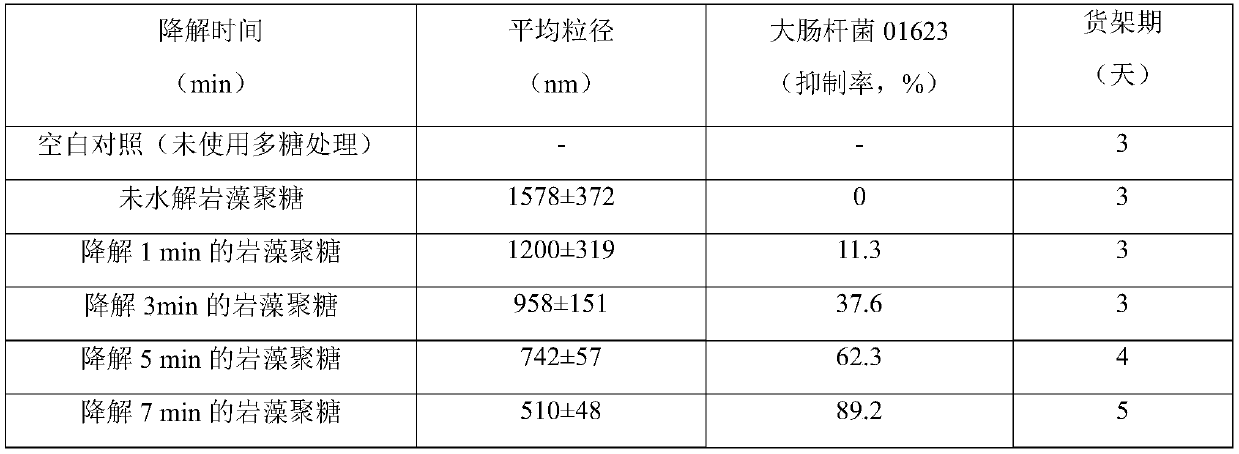

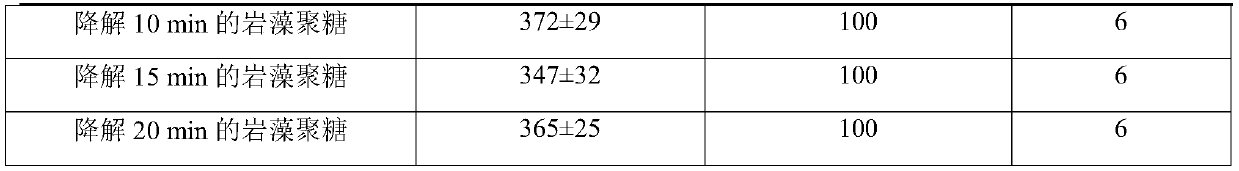

Method used

Image

Examples

Embodiment 1

[0021] A nano-preservative for cold fresh pork, comprising mixing sodium alginate dry powder and fucoidan dry powder at a ratio of 80% by mass of sodium alginate dry powder and 20% by mass of fucoidan dry powder; then adding deionized water, The final concentration of the composite polysaccharide aqueous solution is 1.0% by mass; the above-mentioned composite polysaccharide aqueous solution is degraded in a high-pressure steam cooker with a temperature of 121°C and a pressure of 102.9kPa for 10min, and after cooling to room temperature, the composite polysaccharide nano-liquid is obtained, and the Malvern nanoparticle size is used. Instrument analysis showed that the average particle diameter of the composite polysaccharide was 350nm; the composite polysaccharide nano-liquid was spray-dried to obtain the dry powder of the cold-fresh pork nano-preservative.

[0022] To use, follow the steps below:

[0023] Step 1: dissolving the dry powder of the above-mentioned nano-preservati...

Embodiment 2

[0027] A nano-preservative for cold fresh pork, comprising mixing sodium alginate dry powder and fucoidan dry powder at a ratio of 90% by mass of sodium alginate dry powder and 10% by mass of fucoidan dry powder; then adding deionized water, The final concentration of the composite polysaccharide aqueous solution is 1.0% by mass; the above-mentioned composite polysaccharide aqueous solution is degraded in a high-pressure steam cooker with a temperature of 121°C and a pressure of 102.9kPa for 10min, and after cooling to room temperature, the composite polysaccharide nano-liquid is obtained, and the Malvern nanoparticle size is used. Instrument analysis showed that the average particle diameter of the composite polysaccharide was 350nm; the composite polysaccharide nano-liquid was spray-dried to obtain the dry powder of the cold-fresh pork nano-preservative.

[0028] To use, follow the steps below:

[0029] Step 1: dissolving the dry powder of the above-mentioned nano-preservati...

Embodiment 3

[0033] A nano-preservative for cold fresh pork, comprising mixing sodium alginate dry powder and fucoidan dry powder at a ratio of 95% by mass of sodium alginate dry powder and 5% by mass of fucoidan dry powder; then adding deionized water, The final concentration of the composite polysaccharide aqueous solution is 1.0% by mass; the above-mentioned composite polysaccharide aqueous solution is degraded in a high-pressure steam cooker with a temperature of 121°C and a pressure of 102.9kPa for 10min, and after cooling to room temperature, the composite polysaccharide nano-liquid is obtained, and the Malvern nanoparticle size is used. Instrument analysis showed that the average particle diameter of the composite polysaccharide was 350nm; the composite polysaccharide nano-liquid was spray-dried to obtain the dry powder of the cold-fresh pork nano-preservative.

[0034] To use, follow the steps below:

[0035] Step 1: dissolving the dry powder of the above-mentioned nano-preservativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com