Special flour for fried glutinous rice balls with sesame seeds, as well as making method and application of special flour

A production method and a technology of special powder, which are applied in the field of food processing, can solve the problems of no standardized production process, no guarantee of product hygiene, and no fried food has been seen, and achieve simple and fast preparation methods, solve circulation, and improve chemical efficiency. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Main ingredient 1: 100 parts raw glutinous rice flour;

[0036] Main ingredient 2: 100 parts cooked powder;

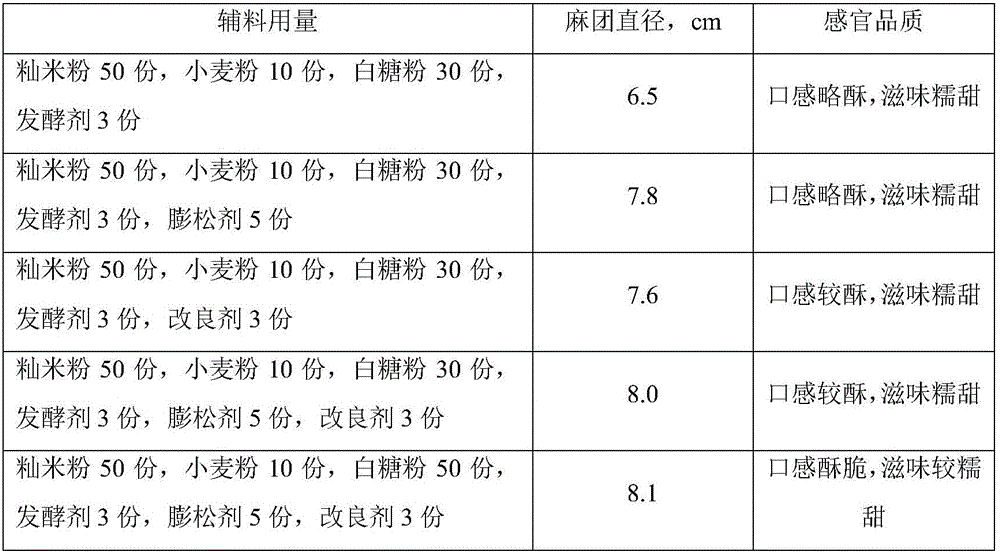

[0037] Excipient 1: 50 parts of indica rice flour, 10 parts of wheat flour, 30 parts of white sugar powder, 3 parts of leavening agent, 5 parts of leavening agent, 3 parts of improving agent;

[0038] The cooked powder raw material is glutinous rice flour.

[0039] The leavening agent comprises the following components in parts by weight: 200 parts of sodium bicarbonate, 120 parts of glucono-δ-lactone, and 170 parts of calcium carbonate.

[0040] The improving agent comprises the following components in parts by weight: 80 parts of amylase, 3 parts of lipase, 5 parts of protease, 0.5 part of TG enzyme (transglutaminase) and 0.5 part of vitamin C.

[0041] The main ingredient 1, the main ingredient 2, and the auxiliary ingredients are evenly mixed to obtain the special powder for sesame balls.

[0042] Production of main ingredient 2: add 1 times the weight of...

Embodiment 2

[0044] The comparison of embodiment 2 main material 2 preparation methods

[0045] With embodiment 1, main ingredient 2 preparation method 1 is with embodiment 1.

[0046] Production method 2 is as follows: mix the raw materials of main ingredient 2 with white sugar powder, heat with supersaturated steam (120°C) for 30 minutes, dry with hot air (80°C, 60 minutes), and pulverize to obtain main ingredient 2. The water content of main ingredient 2 was measured to be 11.8%.

[0047] Production method 3 is: soak the cooked powder raw materials in water, steam at 120°C, cool to room temperature, let stand at 20°C for 3 hours, dry (microwave 250w / g, 20min, take out and stir, then hot air at 60°C for 2h), pulverize to obtain main Material 2. The water content of the main ingredient 2 was measured to be 10.3%, and the quality of the rice balls is shown in Table 1.

[0048] Table 1 The influence of the main material 2 production method on the quality of sesame balls

[0049]

[0...

Embodiment 3

[0051] The comparison of the consumption of embodiment 3 major ingredient 2 (cooked powder)

[0052] With embodiment 1, main ingredient 2 consumption is different. See Table 2 for the dosage of main ingredient 2 and the quality of the dough.

[0053] Table 2 The effect of the amount of main ingredient 2 on the quality of sesame balls

[0054] Amount of cooked powder, part Dump diameter, cm taste Taste color Fat content,% Moisture content,% 0 5.5 6.2 6.1 7.6 46.2 8.1 50 6.2 9.3 8.6 8.9 40.3 8.0 100 8.0 9.6 9.0 9.1 39.4 8.0 300 8.3 8.5 7.6 7.8 33.2 7.9

[0055] It can be seen from Table 2 that the addition of different main ingredients 2 has an impact on the quality of the final mochi product. With the increase of the addition amount, the diameter of the mochi becomes larger, the fat content decreases, the taste is more fluffy, and the sensory quality is improved. , but it is also not suitable for adding too much...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com