Line laser weld detection device for vertically articulated six-axis industrial robot

A technology of industrial robots and vertical joints, applied in the direction of optical devices, measuring devices, instruments, etc., can solve problems affecting image quality, welding deviation, and laser sensor arc light, etc., to improve tracking accuracy, ensure effective application, reduce effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

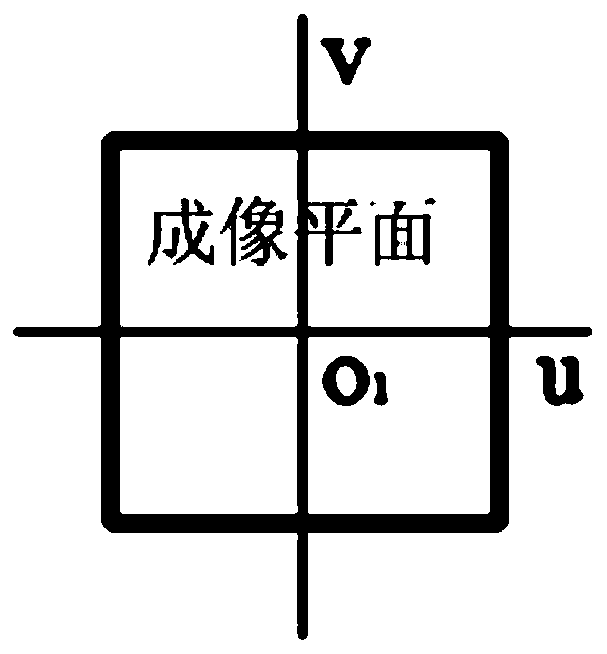

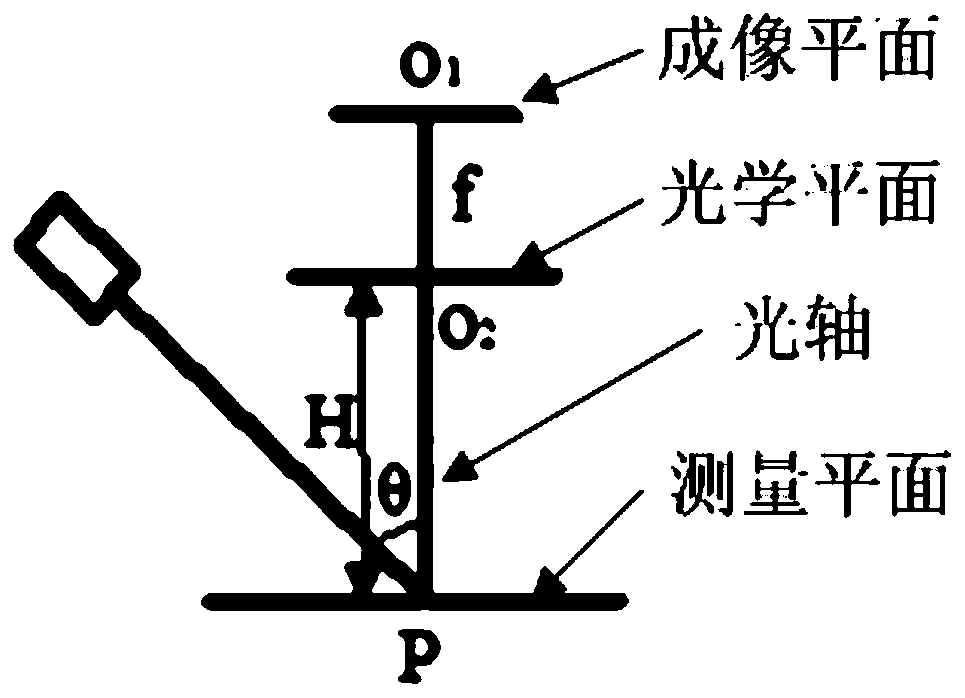

[0032] Such as Figure 3 to Figure 5 As shown, a line laser seam detection device suitable for a vertically articulated six-axis industrial robot includes a laser sensor 3 and a sensor mounting base 4, and the laser sensor 3 is fixed on the front end of the welding torch 2 through the sensor mounting base 4 for Use the principle of triangulation to obtain weld information; the sensor mounting base 4 is used to adjust the relative position and installation angle of the three-dimensional space in the X, Y, and Z directions between the laser sensor and the welding torch, and the sensor mounting base 4 has insulation Function to realize the insulation between the sensor and the welding workpiece.

[0033]Specifically, the sensor mounting base 4 includes a sensor base fixing plate 41, an industrial hinge hinge 42, a sensor mounting side plate 43, a sensor mounting substrate 44, a sensor movable bottom plate 45, a sensor base left support bar 46, and a sensor base right support. Ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com