Chemical plating solution for Ni-P plated layer and controllable preparation method of micro-nano mold

A technology of chemical plating solution and coating, applied in liquid chemical plating, coating, metal material coating process and other directions, can solve the problems of slow deposition rate, uniformity, hardness and corrosion resistance of the coating, and improve the processing Efficiency and processing quality, reduction of processing cost, effect of increased deposition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

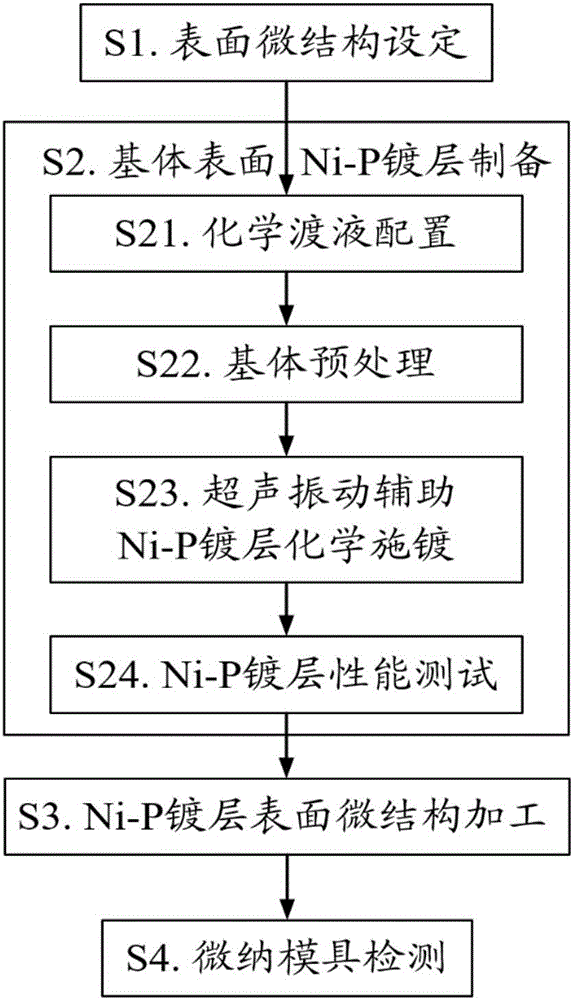

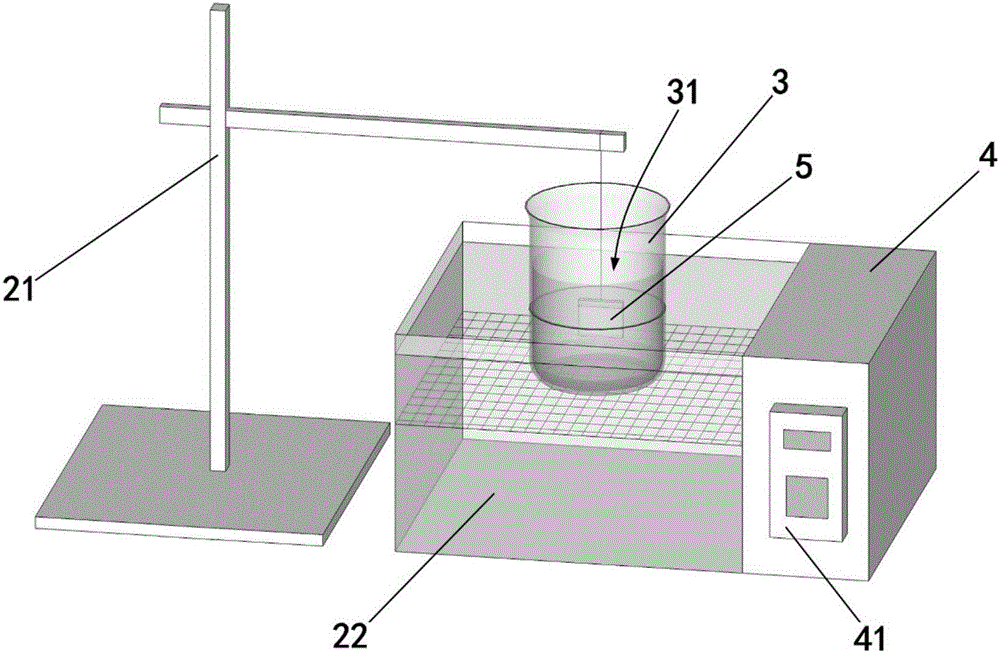

Method used

Image

Examples

Embodiment approach

[0054] As an embodiment of the present invention, this embodiment provides a Ni-P plating electroless plating solution, including NiSO as the main salt 4 ·6H 2 O, NaH as reducing agent 2 PO 2 ·H 2 O, and complexing agents and stabilizers, among them, NiSO 4 ·6H 2 The concentration of O is greater than 25g / L; NaH 2 PO 2 ·H 2 The concentration of O is 16-28g / L.

[0055] A kind of commonly used Ni-P coating electroless plating solution formula that exists in the prior art is: concentration is 25g / L NiSO 4 ·6H 2 O, NaH at a concentration of 25g / L 2 PO 2 ·H 2 O, the concentration is 25g / L sodium acetate (CH 3 COONa), boric acid (H 3 BO 3 ), and the concentration as stabilizer is the thiourea of 2g / L, and the pH value of plating solution is adjusted to 5.8.

[0056] As the preference of this embodiment, choose NiSO 4 ·6H 2 The concentration of O is 27g / L; Complexing agent selects lactic acid and propionic acid, wherein, the concentration of lactic acid is 25g / L, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com