SEBS-based eco-friendly TPO automobile internal decorating material and preparation method thereof

An automotive interior and environment-friendly technology, which is applied in the field of SEBS-based environment-friendly TPO automotive interior materials and its preparation, can solve problems such as hard hand feeling, poor process control, and obvious rubber smell, so as to reduce VOC content and improve soft performance , Improve the effect of soft feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

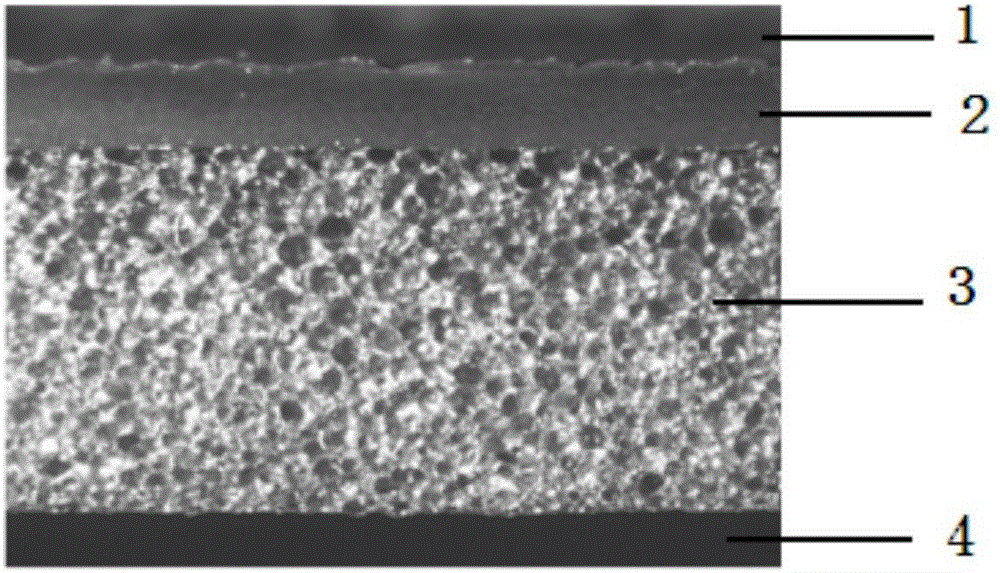

[0039] Such as figure 1 As shown, the environment-friendly TPO automotive interior material based on SEBS is disclosed in the present embodiment, which includes from top to bottom: paint layer 1, TPO skin layer 2, sponge layer 3, and base layer 4. In this embodiment, soft TPO skin and soft sponge formula improve the soft feel of the interior materials and increase the comfort of the product, and the surface is coated with soft water-based polyurethane paint, compounded with soft sponge, and the three-layer structure improves the softness of the material performance, reducing the density of the product, meeting the demand for lightweight products, reducing the VOC content of materials in the car, and improving the environmental protection of the product.

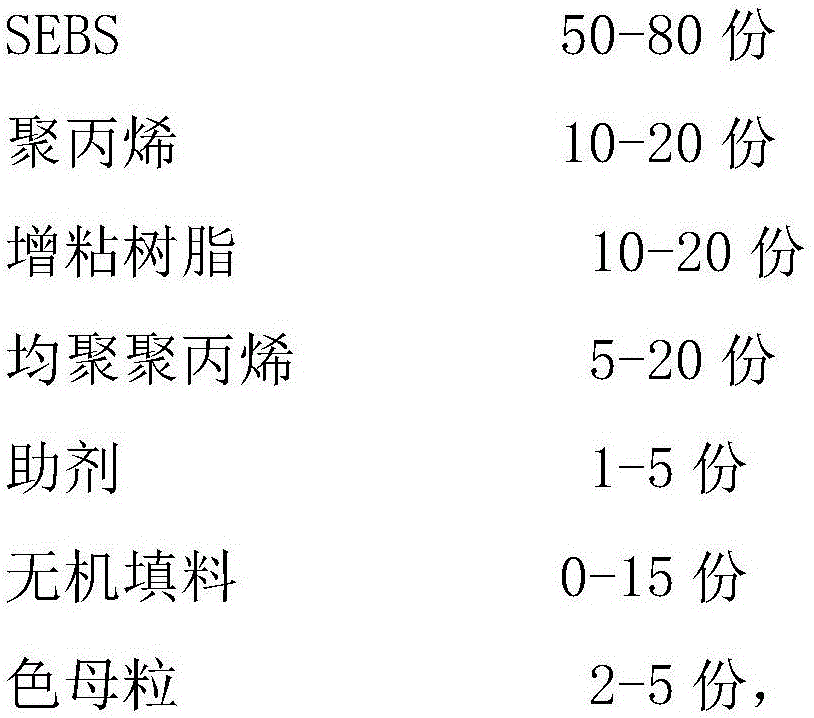

[0040] Wherein, according to parts by weight, the above-mentioned TPO skin layer includes:

[0041]

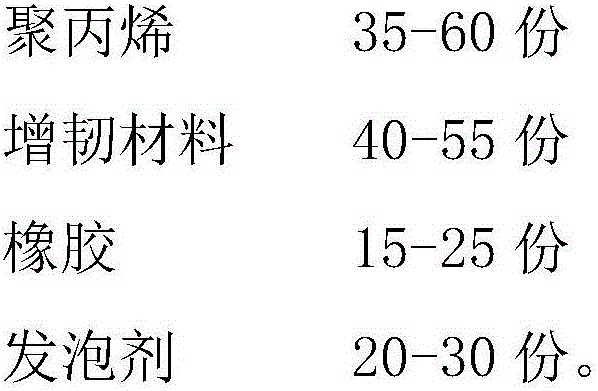

[0042] Above-mentioned sponge layer comprises:

[0043]

[0044] Wherein, the above-mentioned homopolypropylene inc...

Embodiment 2

[0063] In the present embodiment, the above-mentioned TPO skin layer includes:

[0064]

[0065] Above-mentioned sponge layer comprises:

[0066]

[0067] The above-mentioned homopolypropylene includes 60-90% highly crystalline polypropylene homopolymer with a melt flow rate of 50-200 g / 10min, 10-40% highly crystalline polypropylene with a melt flow rate of 150-1000g / 10min Homopolymer.

[0068] The above-mentioned tackifying resin includes rosin resin, terpene resin, hydrocarbon resin, and the ring and ball softening point of the above-mentioned tackifying resin is 140-150°C.

[0069] Wherein, the above-mentioned additives include: metal soaps, phenols, stearic acid complex ester, phosphorous acid.

[0070] The above-mentioned inorganic fillers include: talcum powder, calcium carbonate, barium sulfate, montmorillonite, and nano glass microspheres, and the particle size of the above-mentioned inorganic fillers is 3500 mesh.

[0071] The above-mentioned rubbers include:...

Embodiment 3

[0086] The above TPO epidermis includes:

[0087]

[0088]

[0089] Above-mentioned sponge layer comprises:

[0090]

[0091] The above-mentioned homopolypropylene includes 60-90% highly crystalline polypropylene homopolymer with a melt flow rate of 50-200 g / 10min, 10-40% highly crystalline polypropylene with a melt flow rate of 150-1000g / 10min Homopolymer.

[0092] Wherein, the tackifying resin includes rosin resin, terpene resin, hydrocarbon resin, and the ring and ball softening point of the tackifying resin is 140-150°C.

[0093] The above-mentioned additives include: metal soaps, phenols, stearic acid complex esters, and phosphorous acid.

[0094] The above-mentioned inorganic fillers include: talcum powder, calcium carbonate, barium sulfate, montmorillonite, and nano glass microspheres, and the particle size of the above-mentioned inorganic fillers is 4000 mesh.

[0095] The above-mentioned rubbers include: NBR, silicone rubber, and EPDM rubber.

[0096] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| Global softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com