Octafluoropropane purifying method and purifying apparatus thereof

A technology of octafluoropropane and purification method, applied in chemical instruments and methods, halogenated hydrocarbon disproportionation separation/purification, organic chemistry and other directions, can solve the problems of difficult purification, small adsorption capacity, difficult to remove, etc., and prolong the required time. , The effect of improving product yield and reducing discharge light weight and discharge weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

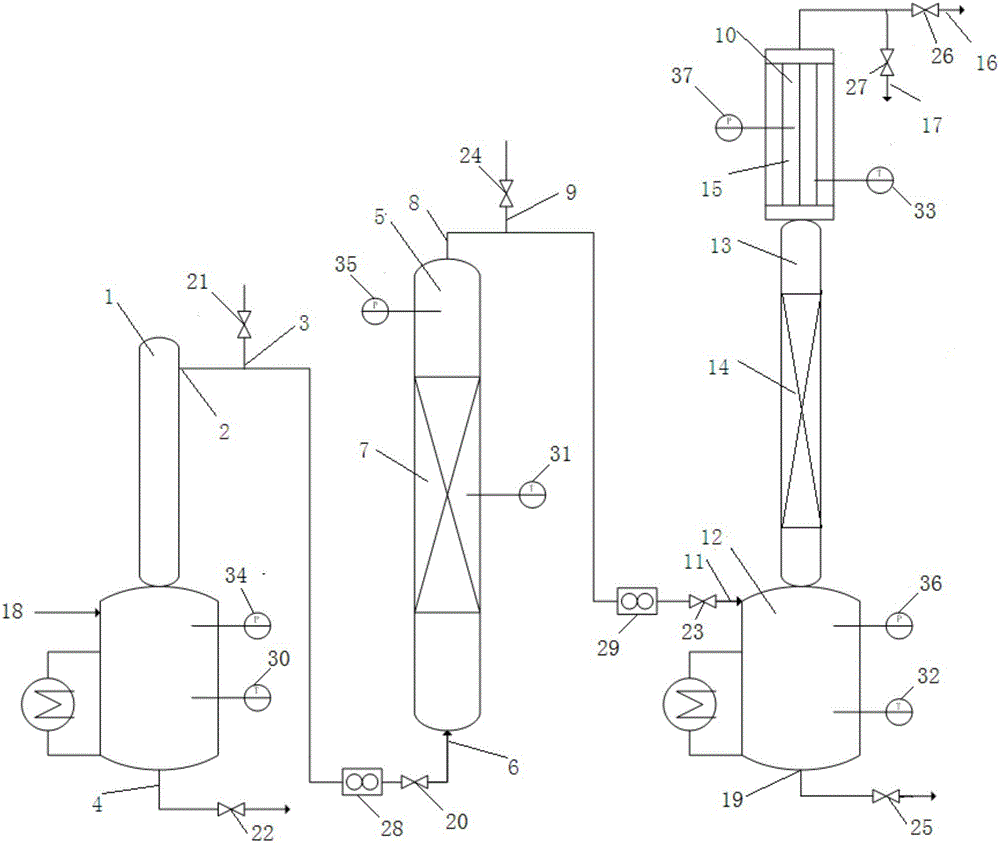

[0054] The rectification tower 10 is a packed rectification tower, the filler 14 is a stainless steel θ ring with a diameter of 1mm, the material of the rectification tower 10 is nickel, the height is 15m, and the diameter of the rectification column 13 is 50mm.

[0055] A purification method of octafluoropropane, the steps of the purification method are as follows:

[0056] (1) The crude octafluoropropane gas is introduced into the cold trap 1 with a temperature of -100°C, the temperature is raised at a rate of 1°C / min, and light removal treatment is carried out at -90°C to -40°C to make the light components with low boiling points Evaporate and discharge. When the temperature rises to greater than -40°C and less than or equal to -20°C, the treated crude octafluoropropane gas is introduced into the bottom of the adsorption tower 5. When the temperature rises to greater than -20°C, stop the flow to the bottom of the adsorption tower 5. In, the higher boiling point heavy compon...

Embodiment 2

[0064] The rectification tower 10 is a packed rectification tower, the filler 14 is a nickel Pall ring with a diameter of 5mm, the material of the rectification tower 10 is stainless steel, the height is 8m, and the diameter of the rectification column 13 is 500mm.

[0065] A purification method of octafluoropropane, the steps of the purification method are as follows:

[0066] (1) Introduce the crude octafluoropropane gas into the cold trap 1 with a temperature of -91°C, raise the temperature at a rate of 2°C / min, and perform light removal treatment at -90°C to -40°C, so that the light component impurities with low boiling points Evaporate and discharge. When the temperature rises to greater than -40°C and less than or equal to -20°C, the treated crude octafluoropropane gas is introduced into the bottom of the adsorption tower 5. When the temperature rises to greater than -20°C, stop the flow to the bottom of the adsorption tower 5. In, the higher boiling point heavy componen...

Embodiment 3

[0074] The rectification tower 10 is a packed rectification tower, and the filler 14 is a polytetrafluoroethylene Pall ring with a diameter of 100mm. The rectification tower 10 is made of Monel alloy and has a height of 5m. The diameter of the rectification column 13 is 300mm.

[0075] A purification method of octafluoropropane, the steps of the purification method are as follows:

[0076] (1) Import the crude octafluoropropane gas into the cold trap 1 with a temperature of -100°C, raise the temperature at a rate of 1.5°C / min, and carry out light removal treatment at -90°C to -40°C, so that the light component impurities with low boiling points Evaporate and discharge. When the temperature rises to greater than -40°C and less than or equal to -20°C, the treated crude octafluoropropane gas is introduced into the bottom of the adsorption tower 5. When the temperature rises to greater than -20°C, stop the flow to the bottom of the adsorption tower 5. In, the higher boiling point ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com