Inorganic high-pressure fireproof wear-resistant decorative plate and production method thereof

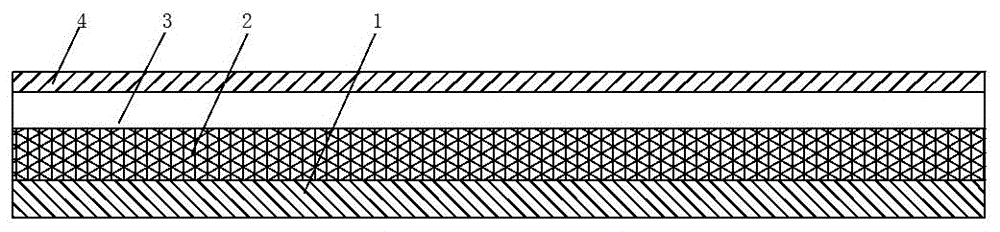

A decorative board, inorganic technology, applied in the field of inorganic high-pressure fireproof wear-resistant decorative board and its production, can solve the problems of high compressive strength, difficult to meet the needs, brittle fracture and other problems, and achieve high tensile strength and bending strength , Good dimensional stability, large penetration depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 of a production method of an inorganic high-pressure fireproof and wear-resistant decorative board includes the following production steps:

[0057] (1) Prepare the alcohol-soluble phenolic resin for impregnating the inorganic non-combustible board, and add 8% flame retardant with the mass of the alcohol-soluble phenolic resin in the later stage of the preparation process, and finally make the resin for impregnating the inorganic non-combustible board;

[0058] (2) Arrange inorganic non-combustible boards such as cement boards, cement fiber boards or glass magnesium boards with a thickness of 3.5 mm on the stainless steel grid frame at intervals of 3 cm, and then dry them at a temperature of 80 ° C for 2 hours and then put them into pressure impregnation Tank, inject the above-mentioned resin for impregnating inorganic non-combustible sheets that has not covered the upper edge of the sheet, pressurize to 0.35MPa, and impregnate at a temperature of 35°C for 1...

Embodiment 2

[0067] Embodiment 2 of a production method of an inorganic high-pressure fireproof and wear-resistant decorative board includes the following production steps:

[0068] (1) Prepare the alcohol-soluble phenolic resin for impregnating the inorganic non-combustible board, and add 9% of the mass of the alcohol-soluble phenolic resin flame retardant in the later stage of the preparation process, and finally make the resin for impregnating the inorganic non-combustible board;

[0069] (2) Arrange inorganic non-combustible boards such as cement boards, cement fiber boards or glass magnesium boards with a thickness of 4.8mm evenly on the stainless steel grid frame at intervals of 4cm, and then dry them at a temperature of 90°C for 2 hours and then put them into pressure impregnation tank, inject the above-mentioned impregnated inorganic non-combustible sheet resin that has not crossed the upper edge of the sheet, pressurize to 0.3MPa, and impregnate at a temperature of 35°C for 150 min...

Embodiment 3

[0078] Embodiment 3 of a production method of an inorganic high-pressure fire-resistant and wear-resistant decorative board, including the following production steps: (1) Prepare an alcohol-soluble phenolic resin for impregnating the inorganic non-combustible board, and add a mass of alcohol-soluble phenolic resin in the later stage of the preparation process 10% flame retardant of the resin mass, finally made into resin for impregnating inorganic non-combustible boards;

[0079] (2) Arrange inorganic non-combustible plates such as cement boards or cement fiber boards or glass magnesium boards with a thickness of 6mm on the stainless steel grid frame evenly at intervals of 5cm, and then dry them at a temperature of 100°C for 2 hours and then put them into a pressurized impregnation tank , inject the above-mentioned resin for impregnating inorganic non-combustible sheets that has not crossed the upper edge of the sheet, pressurize to 0.25MPa, and impregnate at a temperature of 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com