A method for monitoring the working state of the iron core inside the box based on magnetic flux leakage

A technology of working state and iron core, which is applied in the field of monitoring the working state of the iron core inside the box based on magnetic flux leakage, can solve the problems of interference transmission accuracy, influence on reliability, misoperation of relay protection devices, etc., and achieve the goal of avoiding the influence of distortion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings, and a single-phase dual-winding transformer is specifically used to illustrate the specific application of the present invention.

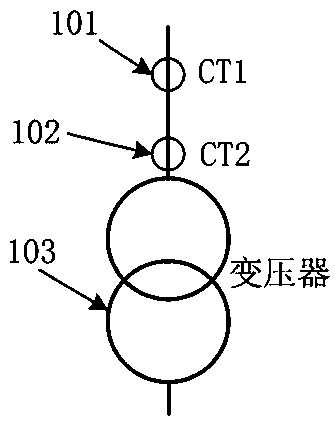

[0027] In the power system, for large-capacity transformers, based on transportation and manufacturing factors, three independent single-phase transformers are usually combined to form a three-phase transformer after installation. The common connection methods of single-phase transformers and the power grid are as follows: figure 1 As shown, two sets of CTs are configured. The line CT 101 is installed near the circuit breaker of the transformer lead, and the transformer bushing CT 102 is installed inside the elevated base above the transformer body, near the windings and cores inside the transformer.

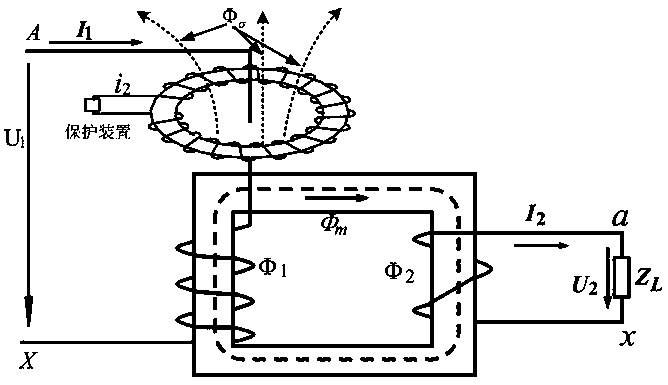

[0028] The internal magnetic flux of the single-phase transformer and the leakage magnetic flux in the bushing area such as figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com