A light-emitting diode chip and its preparation method

A light-emitting diode and chip technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of small number of chips and sacrifice of light-emitting area area, etc., and achieve the effect of increasing the number of chips, reducing the surface area, and saving the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

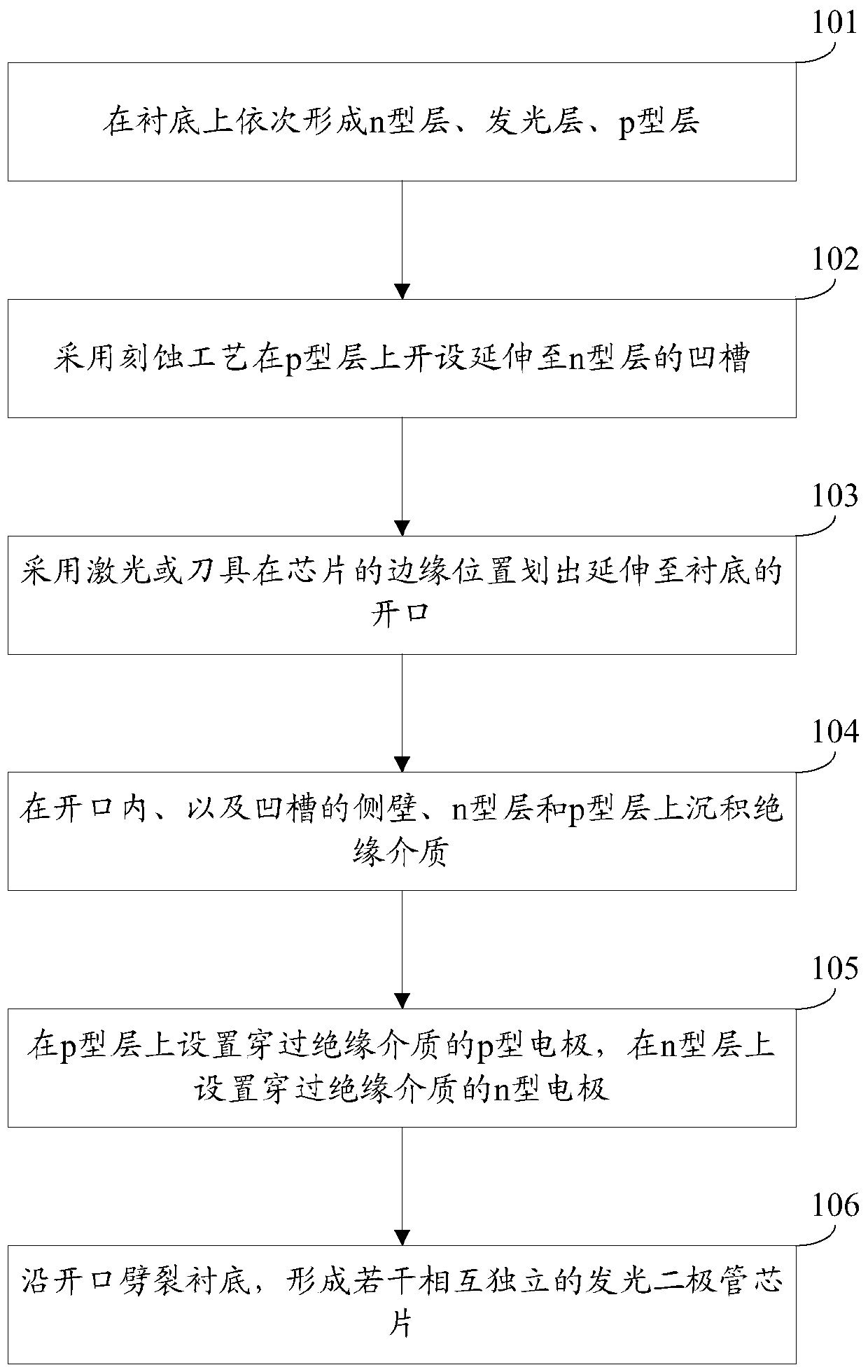

[0034] The embodiment of the present invention provides a method for preparing a light-emitting diode chip, see figure 1 , the preparation method comprises:

[0035] Step 101: sequentially forming an n-type layer, a light-emitting layer, and a p-type layer on a substrate.

[0036] In this embodiment, the substrate can be a sapphire substrate, the n-type layer can be an n-type GaN layer, the light-emitting layer can include alternately stacked InGaN quantum well layers and GaN quantum barrier layers, and the p-type layer can be a p-type GaN layer .

[0037] Step 102: using an etching process to open a groove extending to the n-type layer on the p-type layer.

[0038] Step 103: Using a laser or a cutter to mark an opening extending to the substrate at the edge of the chip.

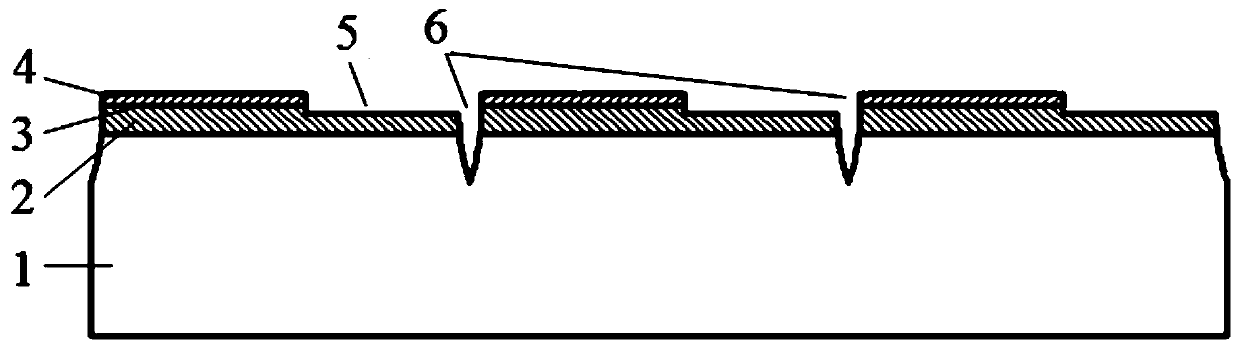

[0039] Figure 2a It is a schematic structural diagram of the light emitting diode chip after step 103 is performed. Wherein, 1 is a substrate, 2 is an n-type layer, 3 is a light-emitting layer, 4 is a ...

Embodiment 2

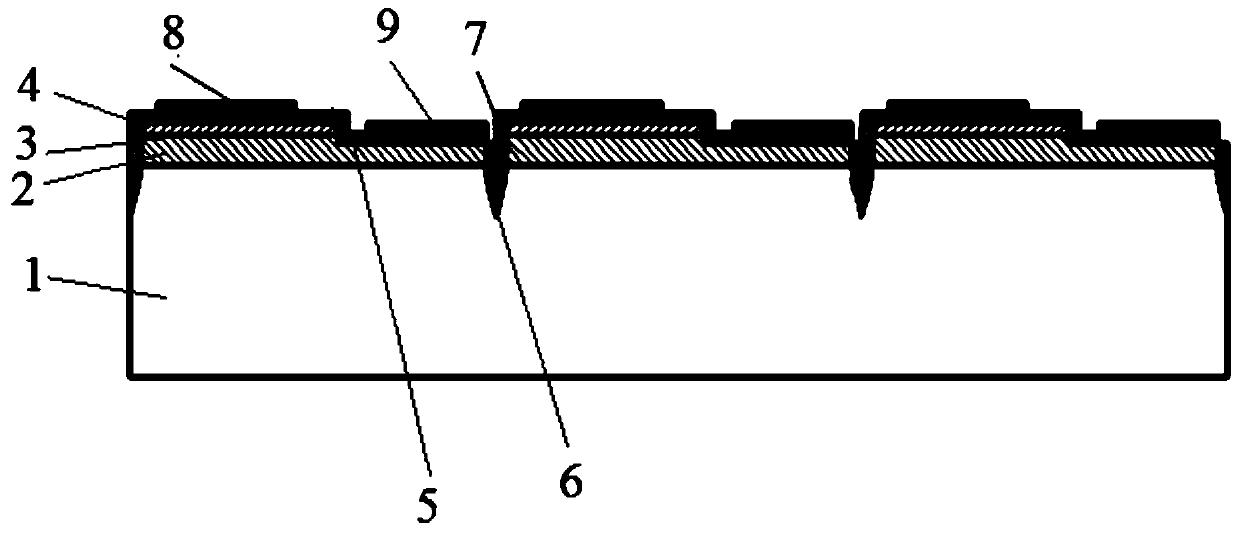

[0068] The embodiment of the present invention provides a light-emitting diode chip, which can be prepared by the preparation method provided in Embodiment 1, see image 3 with Figure 4 The light-emitting diode chip includes a substrate 1, and an n-type layer 2, a light-emitting layer 3, and a p-type layer 4 sequentially stacked on the substrate 1, and a groove 5 extending to the n-type layer 2 is opened on the p-type layer 4 The edge position of the LED chip is provided with an opening 6 extending to the substrate 1, an insulating medium 7 is deposited in the opening 6, on the sidewall of the groove 5, on the n-type layer 2 and the p-type layer 4, and the p-type electrode 8 is set on the p-type layer 4 through the insulating medium 7, and the n-type electrode 9 is set on the n-type layer 2 through the insulating medium 7.

[0069] In the embodiment of the present invention, an opening extending to the substrate is provided at the edge of the light-emitting diode chip, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com