Ship ballast water filter performance experiment device

A technology for ship ballast water and experimental devices, which is applied in the testing of measuring devices, instruments, machinery/structural components, etc. Operating life, good safety and environmental protection effects, and good signal compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the content of the present invention more obvious and understandable, the present invention will be described in detail below in conjunction with specific examples.

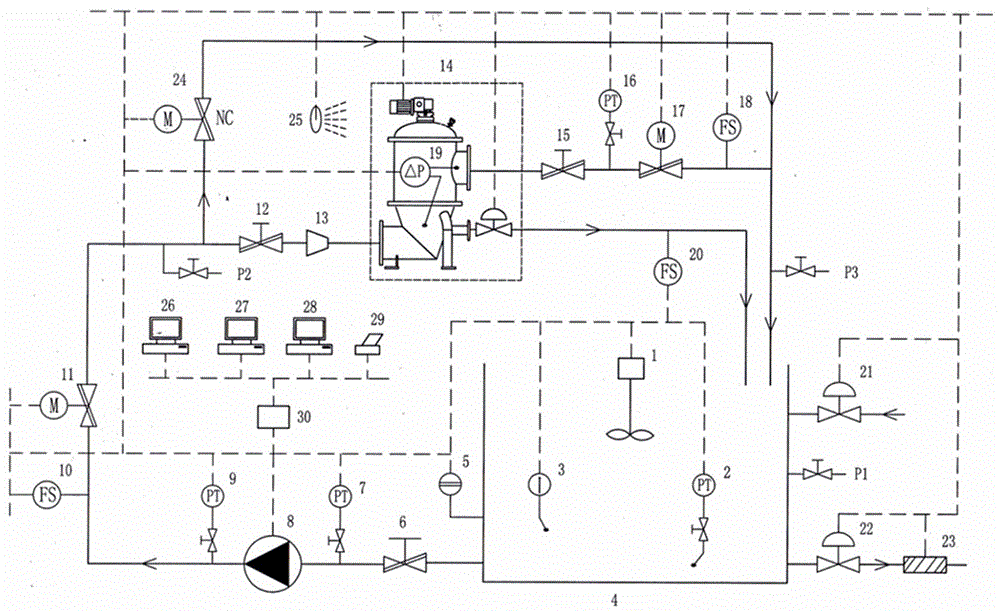

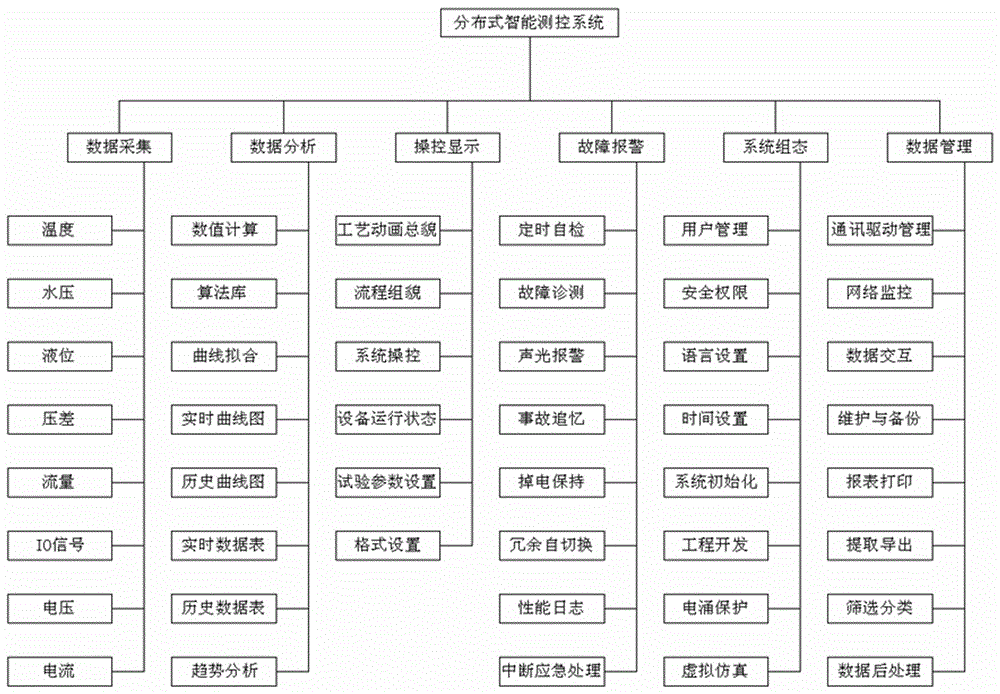

[0027] As shown in the figure, the experimental device for the performance of the ship's ballast water filter includes three parts: a circulating water system unit, a heterogeneous product access unit and a distributed intelligent measurement and control system;

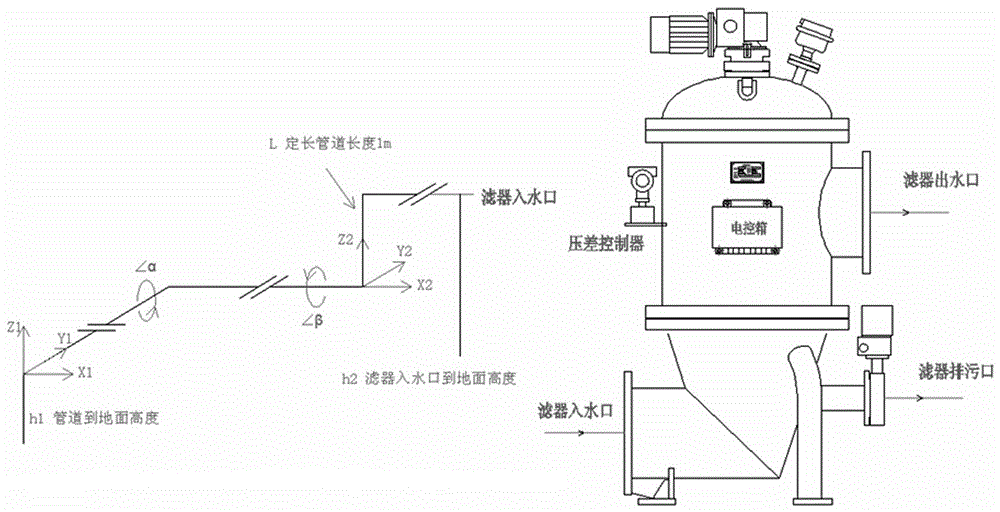

[0028] The circulating water system unit includes a water supply and drainage system, a circulating water tank 4, a first manual valve 6, a water pump 8, a regulating valve 11 and a bypass valve 24, and the water supply and drainage system includes a water injection valve 21 and a drain valve respectively connected to the circulating water tank 4 22. The end of the drain valve 22 of the water supply and drainage system is also connected with a microfilter 23. The water outlet of the circulating water tank 4 is connected to the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com