Far-end plasma reinforced chemical vapor deposition device

An enhanced chemical and vapor deposition technology, used in gaseous chemical plating, metal material coating processes, coatings, etc., can solve the problem of inability to maintain optimal requirements, low plasma density, and poor plasma spatial distribution uniformity. problems, to achieve the effect of improving the use efficiency and process efficiency, increasing the plasma density, and avoiding the low plasma density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

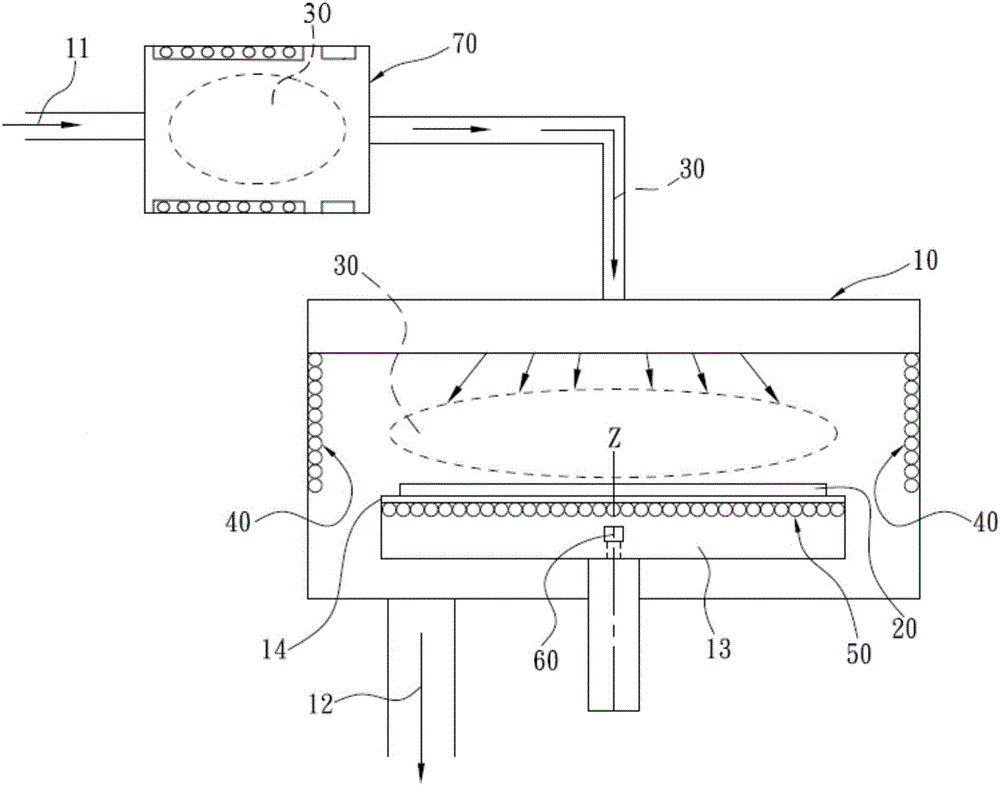

[0038] like figure 1 and figure 2 As shown, the present embodiment provides a preferred remote plasma-enhanced chemical vapor deposition device, which includes a reaction chamber 10 and a remote plasma generation chamber 70 communicated with each other, wherein one end of the remote plasma generation chamber 70 A process gas inlet 11 is provided, and a by-product outlet 12 is provided at the bottom of the reaction chamber 10 . A platform 13 is provided in the reaction chamber 10, and a heating device is provided in the platform 13, which can heat the substrate 20 to provide the temperature required for forming the plasma 30; a platform surface 14 is fixed on the platform 13 for bearing At least one substrate 20, the platform surface 14 here can preferably be set as a rotatable structure, so as to improve the film-forming effect of the reaction chamber. A DC discharge unit 71, a radio frequency discharge unit 72 and a microwave discharge unit 73 are simultaneously and mutual...

Embodiment 2

[0046] This embodiment proposes another preferred remote plasma-enhanced chemical vapor deposition device, which is basically the same as the device in Embodiment 1, with the difference that the setting parameters of each discharge unit and process gas are different.

[0047] In this embodiment, the radio frequency intensity of the radio frequency discharge unit 72 is preferably 11000MHz, 100A / m±3%, that is, when the frequency of the radio frequency discharge unit 72 is 11000MHz, the radio frequency can be in the range of (100±100*3%) A / m The DC intensity of the DC discharge unit 71 is 15KVA / m ± 10%, that is, the DC intensity can be selected within the range of (15 ± 15*10%) KVA / m; the radio frequency intensity of the microwave discharge unit 73 is 120db / w. In addition, the remote plasma generation chamber 70 also uses argon gas as the process gas, but the gas flow intensity of the argon gas is preferably 5˜15 cc / min. Compared with the first embodiment, the parameter range o...

Embodiment 3

[0049] This embodiment proposes a deposition method applicable to the remote plasma-enhanced chemical vapor deposition device, which specifically includes the following steps:

[0050] A: At least one substrate 20 is placed on the platform surface 14 in the reaction chamber 10 , here, the shape of the substrate 20 is not limited, and the number depends on the size of the platform surface 14 .

[0051] B: providing the plasma 30 formed by the process gas into the reaction chamber 10;

[0052] In this step, the plasma 30 is formed from raw materials in the remote plasma generation chamber 70 and then passed into the reaction chamber 10 .

[0053] C1: start the first electric field device 40, the first electric field device 40 is arranged on the peripheral wall of the inner cavity of the PECVD reaction chamber 10, and is used to generate an electric attraction effect on the plasma 30 in the reaction chamber 10, so that the plasma Before the source material or film precursor in 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com