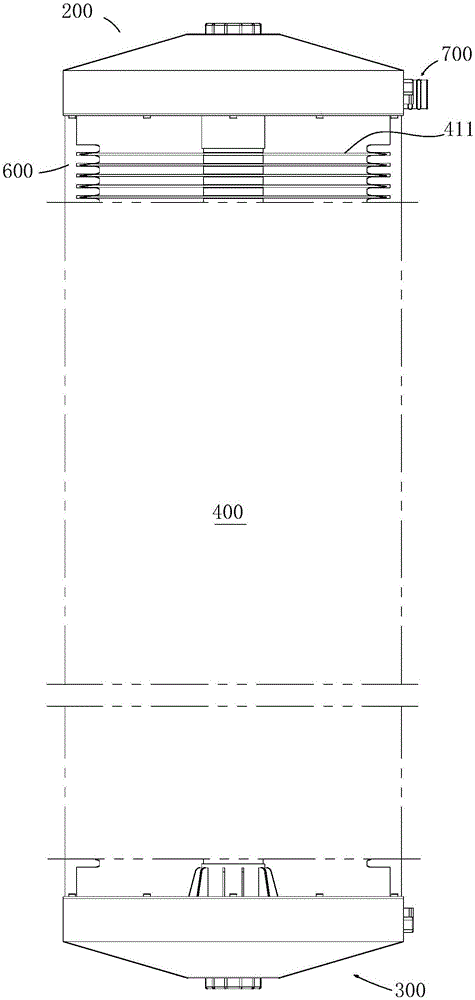

Membrane component used for water treatment

A technology of membrane modules and water treatment, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc. Effective filter area and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

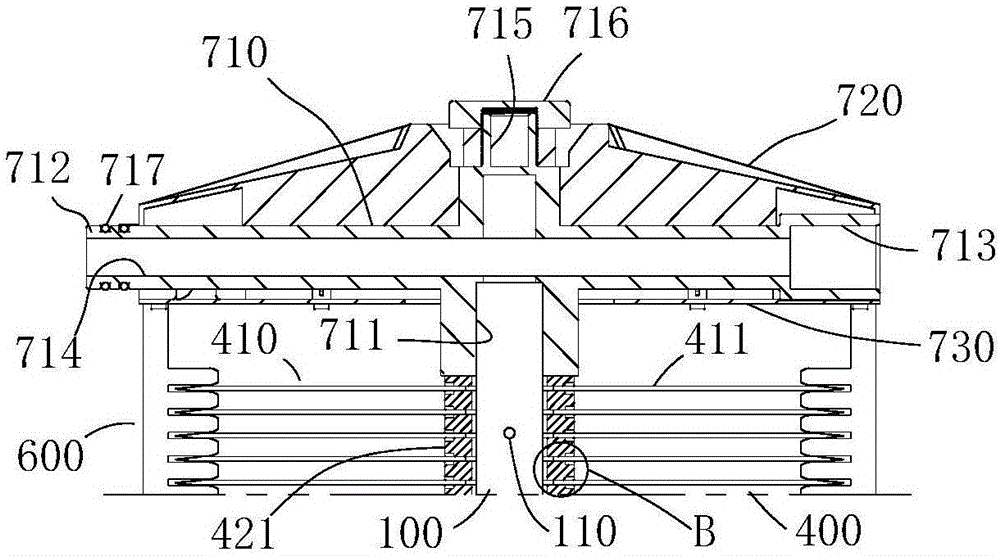

[0043] like Figures 1 to 4 In the MBR membrane module shown, the membrane element 410 adopts a square membrane 411 with the same shape and size. The length or width of the diaphragm 411 is 320 mm. The four corners of the diaphragm 411 are all rounded with a radius of 15 mm. The center of the diaphragm 411 is provided with a through hole 411d. A support plate 411f with a thickness of 1.2mm is provided in the cavity 411c of the diaphragm 411. The support plate 411f is a square solid plate, and the four corners of the support plate 411f are respectively provided with chamfers. An assembly hole 411g is provided at the center of the support plate 411f, and the assembly hole 411g is coaxially arranged with the through hole 411d. The length or width of the square support plate 411f is 20mm smaller than the length or width of the square diaphragm 411, so as to reserve the position of the welding scar 411i. The membrane 411 is made by stacking the support plate 411f and the second...

Embodiment 2

[0049] Replace the support rod 100 of Embodiment 1 with a solid rod. On this basis, the structure of the first interface 711 of the guide adapter 710 is adjusted accordingly, so that the flow path formed by the guide gap 430, the matching gap between the seal ring body 421a and the support rod 100 is set on the support The filtered water in the diversion channel on the surface of the rod 100 directly flows into the diversion adapter 710 from the mating surface between the support rod 100 and the first interface 711 of the diversion adapter 710 . The specific method is to set a diversion hole connected to the diversion tube 714 in the side wall of the first interface 711 of the diversion adapter 710 , and connect the diversion hole to the diversion channel provided on the surface of the support rod 100 .

Embodiment 3

[0051] like Figures 9 to 10 As shown, the membrane 411 of the embodiment 1 is improved, specifically, support nets 411h are provided on the inside of the first filter membrane 411a and the inside of the second filter membrane 411b. like Figure 10 As shown, the improved membrane 411 is after stacking the support net 411h, the support plate 411f, the support net 411h and the second filter film 411b sequentially on the first filter film 411a, and then the edge of the first filter film 411a and the second filter film The edges of the two filter films 411b are heat-processed and fused together, and the edges of the support net 411h inside the first filter film 411a and the support net 411h inside the second filter film 411b are preferably combined in the welding scar 411i. The support net 411h can further support the first filter film 411a and the second filter film 411b, and can better prevent the deformation of the diaphragm 411 when used in conjunction with the support plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com