Processing method for welding of high-tension aluminum silicon coating plated steel plate and splicing structure thereof

A technology of coated steel plate and processing method, which is applied in the field of steel welding, can solve the problems of high daily maintenance cost of optical instruments, influence of coating stripping effect, and increase of production cost, and achieve maintenance cost reduction, processing efficiency improvement, and stripping speed Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

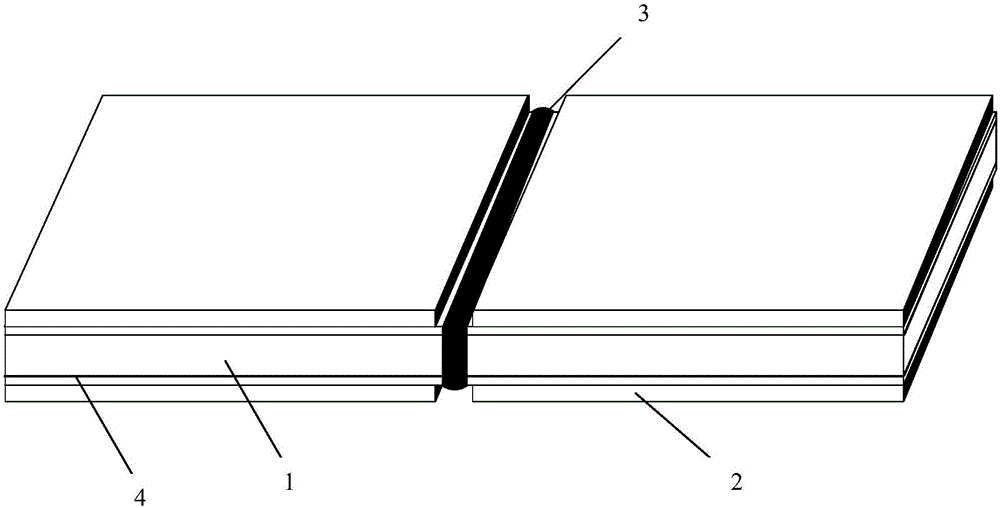

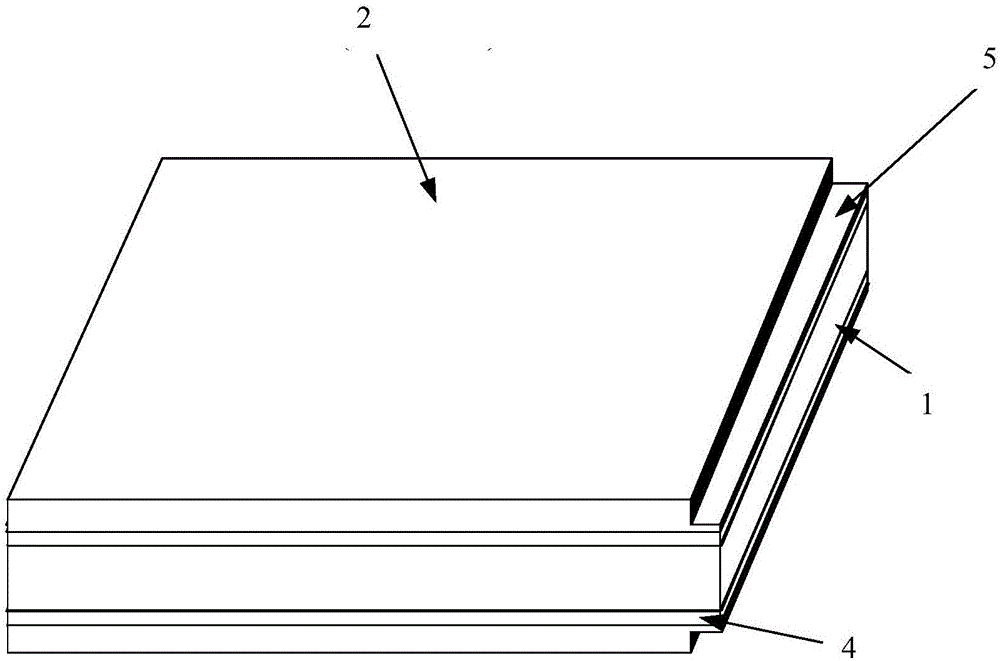

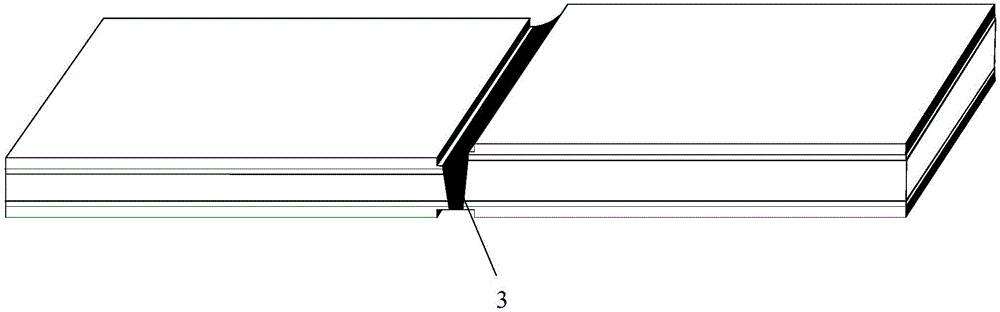

[0026] Embodiment one: see Figure 2~3 As shown, a processing method for welding a high-tensile aluminum-silicon-coated steel plate, wherein the surface of the steel plate 1 to be welded is coated with an aluminum-silicon alloy layer 2, and the surface of the steel plate 1 to be welded is peeled off along the welding edge by a laser beam. Part of the aluminum-silicon alloy layer, the removed part of the aluminum-silicon alloy layer accounts for 90% to 95% of the original aluminum-silicon alloy layer.

[0027] In this embodiment, a laser with an average output power of 900W is used to split the energy and split the light to the positive and negative two aluminum-silicon alloy layers 2 while removing the coating, and the width of the removed part of the aluminum-silicon alloy layer is 0.5mm- 1.0 mm, the thickness is less than 2 microns, after the laser beam peels off part of the aluminum-silicon alloy layer, the steel plate 1 to be welded is laser welded, and the aluminum remain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com