Magnetic biochar adsorbing material and preparation method thereof

An adsorption material and biochar technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of poor connection stability and fast separation speed between magnetic particles and biomass, and achieve a Good appearance, fast separation speed, and stable magnetic core performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

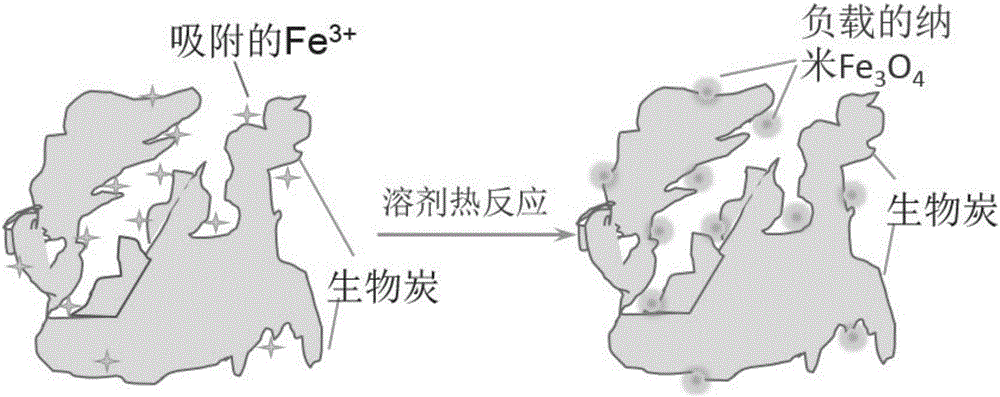

[0035] The preparation method of magnetic biochar adsorption material among the present invention, comprises the following steps:

[0036] (1) Preparation of biochar: use plant biomass (such as agricultural and forestry waste) as raw material after washing, drying, crushing, and powder passing through a 60-mesh sieve, and roast and activate it at 200-1000°C under anaerobic conditions, and the roasting time is controlled In 1-4h, biochar is obtained.

[0037] (2) Preparation of ferric iron precursor solution: ferric salt is dissolved in ethylene glycol by magnetic stirring, and the ratio of solid mass and liquid volume of ferric salt to ethylene glycol is 1: (20-100) (unit mg / L), preferably 1:60, then add anhydrous sodium acetate and surfactant, continue stirring to form a uniform ferric precursor solution, ferric salt in the precursor solution: anhydrous sodium acetate: surface The mass ratio of active agent is controlled between 1:12:3.5-21.

[0038] (3) Preparation of magn...

Embodiment 1

[0043] The preparation method and application examples of the magnetic biochar adsorption material in this embodiment include the following steps:

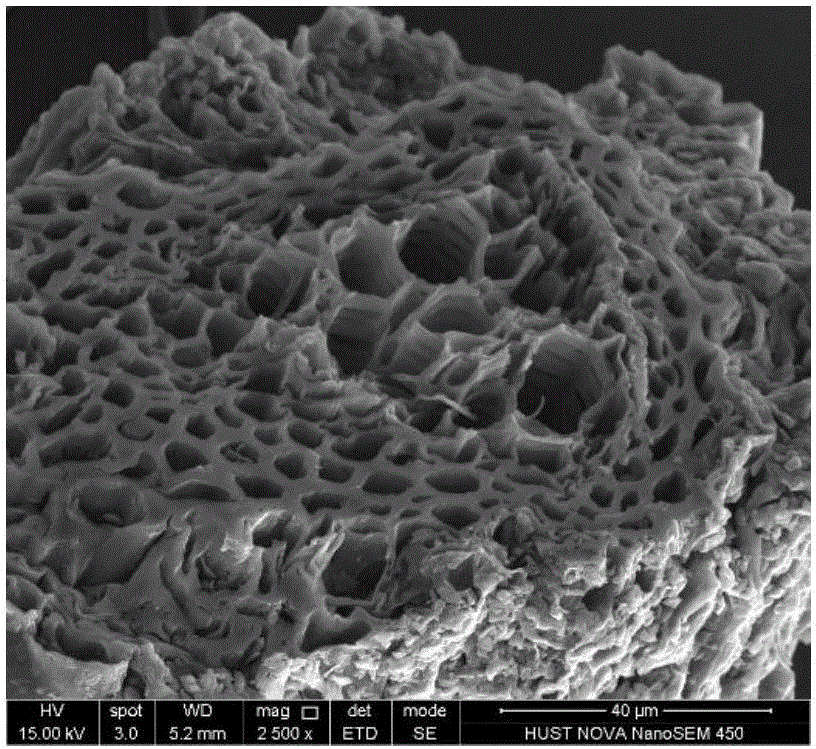

[0044] (1) Preparation of biochar: the agricultural and forestry wastes are the fallen leaves of sycamore collected in the campus, and the powder after washing, drying, crushing and passing through 60 meshes is used as the raw material. Get sycamore leaf biochar, figure 2 Its SEM image.

[0045] (2) Preparation of ferric iron precursor: take 2.7g FeCl 3 ·6H 2 O was dissolved in 80mL of ethylene glycol solution, and then 7.2g of anhydrous sodium acetate and 2g of polyethylene glycol (molecular weight: 4000) were added to it, and stirred continuously for 30min by magnetic stirring to form a uniform emulsion.

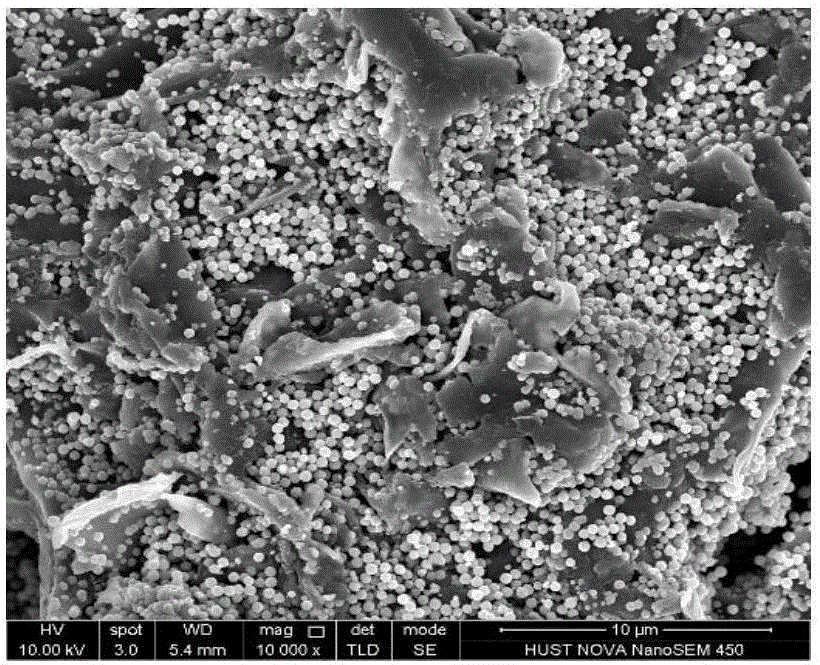

[0046] (3) Preparation of magnetic biochar by solvothermal reaction: add 0.77 g of sycamore-based biochar to the above emulsion, and stir for 2 hours by magnetic force to fully mix the biochar and emulsion.

[0047] (4) P...

Embodiment 2

[0050] The preparation method and application examples of the magnetic biochar adsorption material in this embodiment include the following steps:

[0051] (1) Preparation of biochar: the agricultural and forestry wastes are the fallen leaves of sycamore collected in the campus, and the powder after washing, drying, crushing and passing through 60 meshes is used as the raw material. Get sycamore leaf biochar.

[0052] (2) Preparation of ferric iron precursor: take 2.7g FeCl 3 ·6H 2 O was dissolved in 80mL of ethylene glycol solution, and then 7.2g of anhydrous sodium acetate and 2g of polyethylene glycol (molecular weight: 4000) were added to it, and stirred continuously for 30min by magnetic stirring to form a uniform emulsion.

[0053] (3) Preparation of magnetic biochar by solvothermal reaction: add 1.54 g of sycamore-based biochar to the above emulsion, and stir for 2 hours by magnetic force to fully mix the biochar and emulsion.

[0054] (4) Pour the mixed emulsion int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com