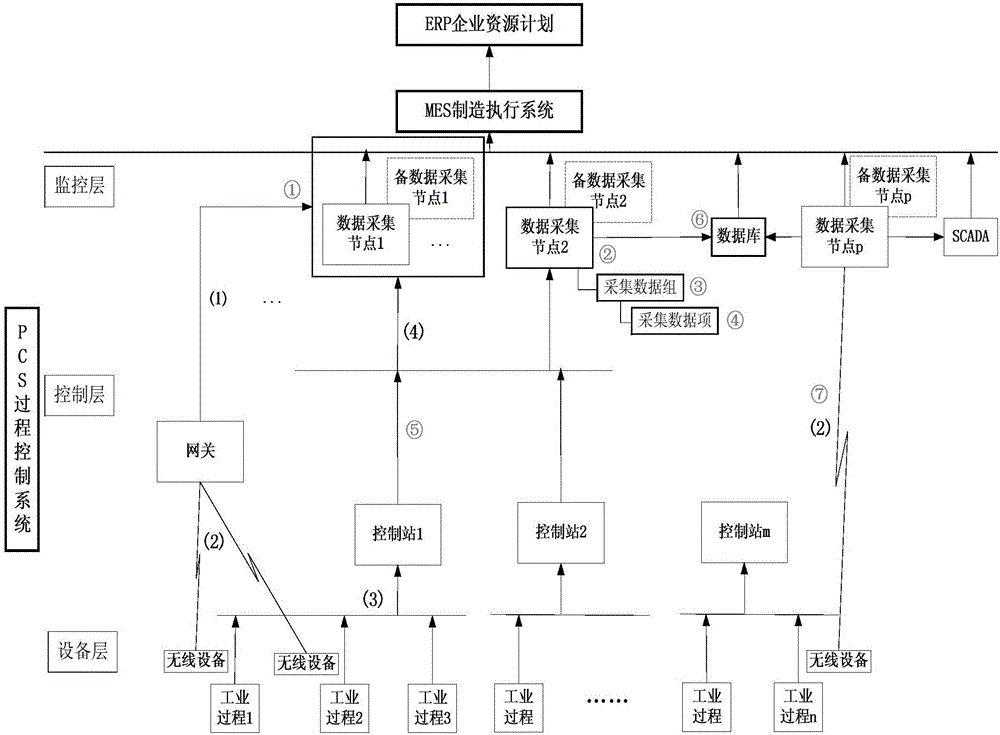

①-⑦ represent the problems existing in the current industrial data

collection system, among which ① represents the 1:1 redundancy of the collection

client, and the

resource utilization rate is low; ② represents the failure of the collection node; ③ represents the failure of the data group collection; ④ represents the failure of the data

item collection ;⑤Indicates that the

acquisition rate is low and the real-time performance is poor;⑥Indicates that data storage fails, the

transmission rate is low, and the data occupies a large space;⑦Indicates

wireless transmission problems

[0007] 3. If figure 1 As shown in ③, when the OPC / OPC-UA protocol is used for collection, even if the data collection nodes are running normally, some or some data groups often fail to be collected. How to capture the failed data groups and provide them with Corresponding solutions to ensure the reliability of data collection are also a major problem in the current industrial data collection process;

[0009] 5. If figure 1 As shown in ⑤, during the data acquisition process of the current industrial data acquisition system, although the underlying data is collected and stored in the

database through the PLC / DCS system, due to the low sampling frequency of the upper-level MES and other systems, the sampling requirements for the upper computer It is not very strict. It often happens that the actual data

collection time is longer than the set collection cycle. For general monitoring or MES application scenarios that do not have strict real-time requirements, this situation can meet the requirements. However, in industrial In the

big data environment, it is often necessary to carry out real-

time correlation analysis on the data collected in each collection cycle, so there are relatively strict requirements on the timing of the data, and the efficiency and reliability of the existing host computer data collection are not enough to meet the requirements

[0011] 7. If figure 1 As shown in middle ⑦, with the wide application of

Internet of Things technology in industry and the access of many

wireless transmission devices, higher requirements and challenges are put forward for data

collection methods[0012] At present, the patents on industrial large-scale distributed data acquisition systems mainly include "CN105527948A (a large-scale distributed data acquisition system and method based on industrial processes)". The system described in this patent uses a data acquisition scheduling module to connect the field control

station The collection task is assigned to multiple data collection clients. When the collection

client fails, in the next collection cycle, the data collection scheduling module can assign other data collection clients to the part according to the detected fault information of the data collection client. The data is collected for data collection, thereby ensuring the high

fault tolerance of the data collection client for data collection. When the

collection time on one or several collection clients exceeds the collection cycle set by the user or there is an overload of the collection client, the data collection scheduling The module restarts the new collection client, and redistributes the collection tasks on all opened collection clients; although the data collection scheduling module in this patent considers the operation status information of the field control

station, data collection Factors such as client operating status information and collection cycle ensure the high reliability of the data collection client to a certain extent, but the system functions described in this patent are not comprehensive enough, and there are the following limitations:

[0013] 1. The system described in this patent can only guarantee the reliability of the next collection cycle and subsequent collection after a fault, and the data in the current collection cycle of the fault will still be lost;

[0014] 2. The system described in this patent only guarantees the reliability of collection when the collection client fails or is overloaded. For the failure of collection of a certain data group or data item on the collection client, no corresponding solution is proposed to ensure collection reliability ;

[0015] 3. This patent can only realize the collection of wired data, and does not provide a corresponding method for

wireless transmission of data;

[0017] 5. The functions of the system described in the patent are not perfect, lack of

user management functions, and it is difficult to verify user identities, thereby ensuring system security; lack of

log management functions, it is difficult to query historical collection and storage results and historical alarm information, so as to check the system The traces left by historical failures, and the system is upgraded and maintained according to the historical records; lack of collection task backup and local data persistence functions, when data collection fails or storage fails, the

fault tolerance of data collection and storage cannot be guaranteed; lack

Data compression function, large

data transmission volume and large storage space lead to low data

storage efficiency and

low resource utilization; lack of monitoring and alarm function, it is difficult for the staff to find the fault at the first time when a fault occurs, so as to carry out related

fault handling;

[0018] To sum up, the current industrial data acquisition system has obvious deficiencies in terms of reliability, effective use of resources, and system functions, and it is difficult to meet the needs of reliable acquisition of real-

time data in the process of

manufacturing enterprises' transformation to intelligence.

Login to View More

Login to View More  Login to View More

Login to View More