Flexible pole piece, preparation method of flexible pole piece, flexible battery and flexible mobile phone

A flexible battery, flexible technology, applied in the direction of battery electrodes, telephone structure, secondary battery manufacturing, etc., can solve the problems of easy material drop, poor bending performance, etc., to achieve improved mechanical strength, good bendable performance, easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

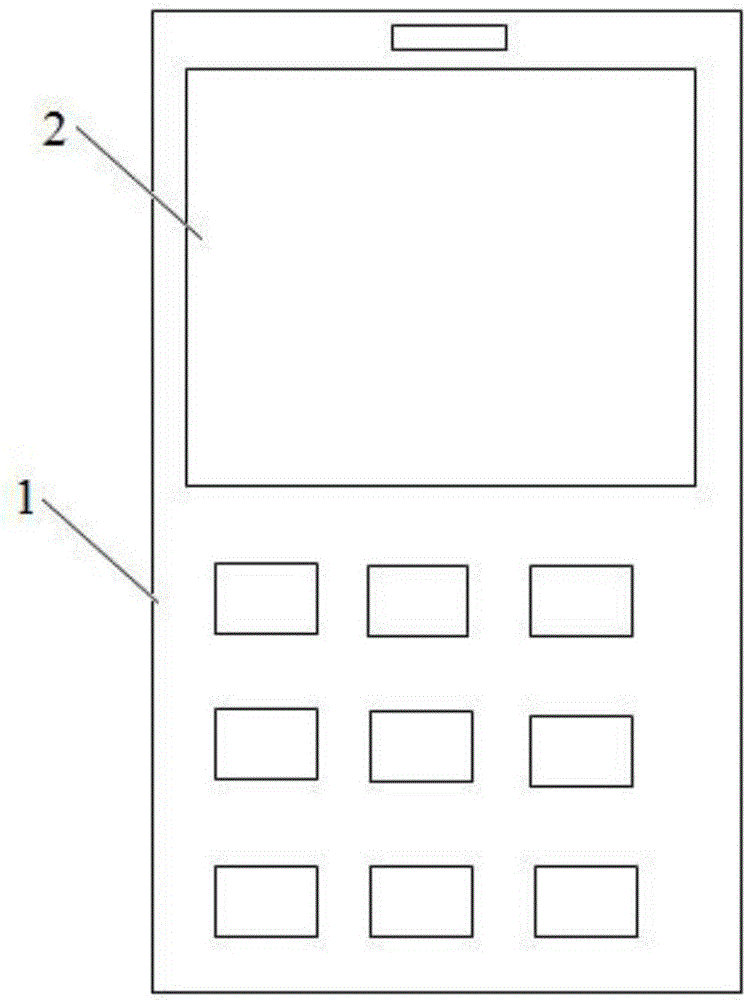

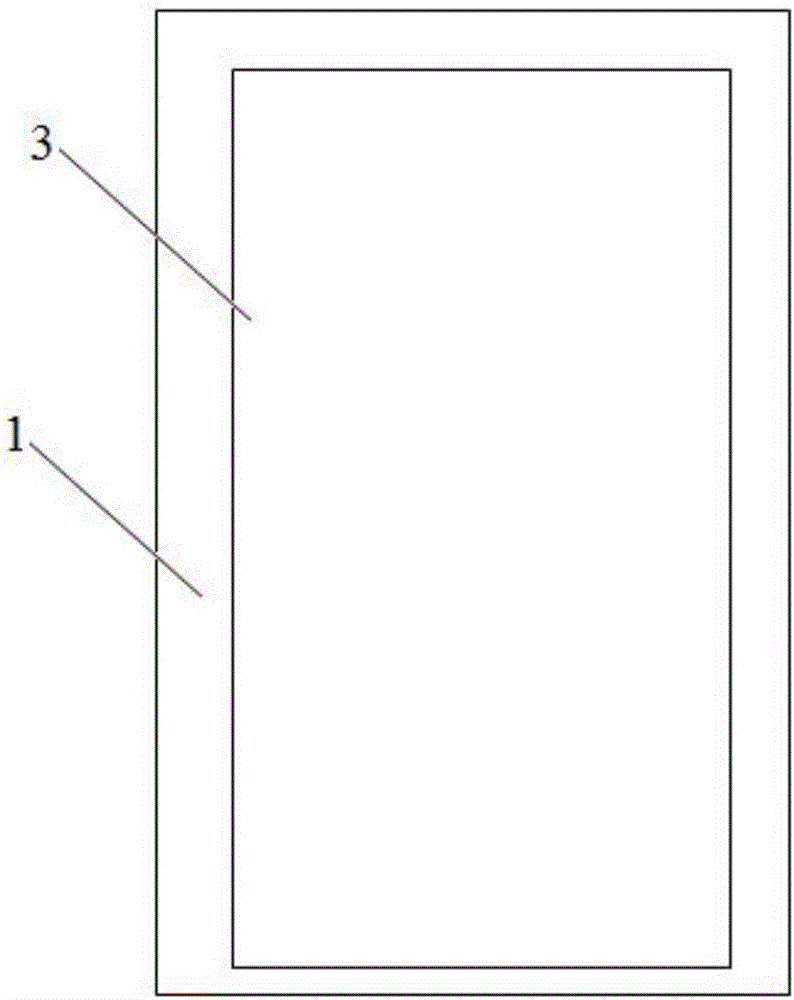

[0030] Such as Figure 1-Figure 4 , the embodiment of the present invention provides a flexible mobile phone, including a flexible housing 1, a flexible circuit board (not shown), a flexible screen 2 and a flexible battery 3, the flexible circuit board and the flexible battery 3 are installed on the In the flexible housing 1, the flexible screen 2 is installed on one side of the flexible housing 1; the flexible circuit board is electrically connected to the flexible battery 3 through flexible wires, and the flexible screen 2 is The wire is electrically connected with the flexible circuit board. Among them, the components contained in the above-mentioned flexible mobile phone are the same as those contained in the existing ordinary mobile phones. It is no different from the assembly method of the existing common mobile phone. For example: the above-mentioned flexible battery 3 is electrically connected to the charging and discharging control system module of the flexible circ...

Embodiment 2

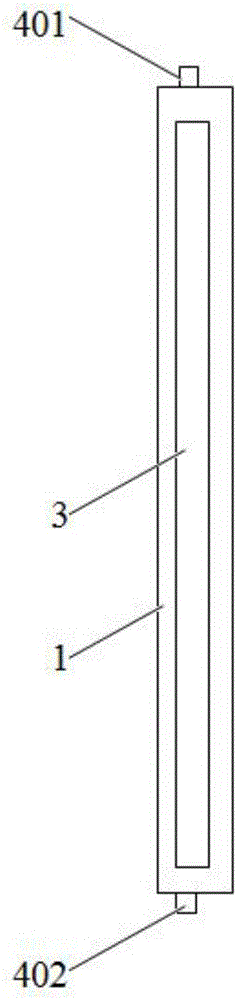

[0038] Such as Figure 5 , the embodiment of the present invention relates to a method for preparing a flexible pole piece, comprising the following steps:

[0039] Step 1, mixing and stirring the active material, conductive agent, binder and solvent to form a uniformly dispersed suspension;

[0040] Step 2, adding cellulose to the suspension and stirring to obtain viscous slurry 301;

[0041] Step 3, the viscous slurry 301 is laid on the metal mesh 302 by rolling film process, and the flexible pole piece is obtained after drying.

[0042]In the embodiment of the present invention, active material, conductive agent, binder, solvent and cellulose are used to prepare battery pole pieces. The binder can make the active material material adhere to the metal mesh 302 while maintaining the adhesion between the active material particles. knot effect; cellulose can play a supporting role. By laying the slurry on the metal mesh 302, the metal mesh 302 can play the role of a current c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com