Bacillus with high temperature resistance and cellulose degradation capacity and application thereof

A technology of cellulose degradation and bacillus, applied in the fields of application, bacteria, organic fertilizers, etc., can solve the problems of pectin and hemicellulose component decomposition, high temperature tolerance and other problems, achieve low cost of cultivation, rapid reproduction, The effect of facilitating the implementation of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Isolation, purification and preservation of strains

[0026] The rotten rice straw and soil were taken from the Shanghai Jiaotong University Pujiang Green Valley Experimental Base in Pujiang Town, Minhang District, Shanghai as samples. 10 g of different samples were ground and placed in 100 mL enrichment medium for constant temperature cultivation at 37 °C and 150 rpm. Every 5 days, 10% of the inoculum was added to another enriched medium, and the acclimatization was repeated 4 times. The enrichment medium adopts the medium with CMC-Na as the sole carbon source.

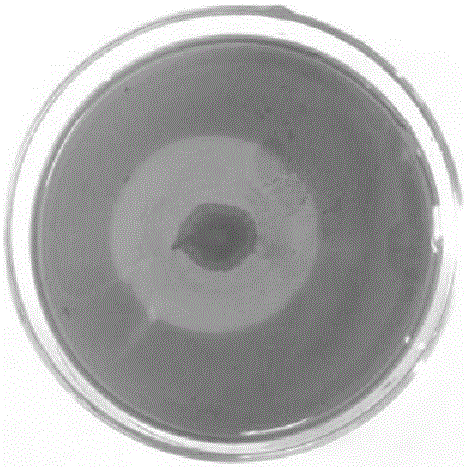

[0027] Take 100 μL of the enrichment solution and spread it on the CMC-Congo red medium plate, and then culture it upside down in a 35°C incubator at a constant temperature. Observe after 5 days that a transparent hydrolysis circle appears on the plate. Pick a small amount of bacteria and streak on LB solid medium until a single colony is obtained, and then continuously culture the obtained single colony o...

Embodiment 2

[0040] Preparation of High Temperature Composting Bacteria

[0041] The bacteria were inoculated in LB liquid medium, and after 24 hours, samples were taken to determine the concentration of the bacteria solution was about 2.0×10 10 After cfu / mL, stop the fermentation. Mix each liter of bacterial liquid with 0.4-0.6 kg of rice straw to prepare a high-temperature compost bacterial agent.

Embodiment 3

[0043] Application of High Temperature Composting Bacteria in Rice Straw Composting

[0044]The rice straw is crushed to 3-5cm by crushing equipment to form a straw segment, and 1.0% of the weight of the straw is added to the compost bacterial agent, and the water content of the pile is adjusted to about 65%. Measure the temperature of the heap body every day. At the beginning, the temperature of the heap body will rise rapidly to around 70°C and maintain for 1-2 days. When the temperature reaches the peak and gradually drops below 45°C, it means that the fermentation is completed (such as Figure 7 ). The whole composting process is about 7-8 days and the compost is turned once, and the compost is turned 3 times in total. After the third turning is completed, the straw bio-organic fertilizer is obtained.

[0045] After searching the prior art, it is found that Chinese Patent Document No. CN103013887, published on 2013-04-03, discloses a Bacillus pumilus KMXU56, and its pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com