A biphenyl hydrophobic monomer and leakage plugging gel based on the monomer

A technology of hydrophobic monomer and bis-phenyl, applied in the field of plugging gel and bis-phenyl hydrophobic monomer, can solve the problems of false plugging, plugging failure, leakage, etc., achieves low cost, is beneficial to industrial production and production simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

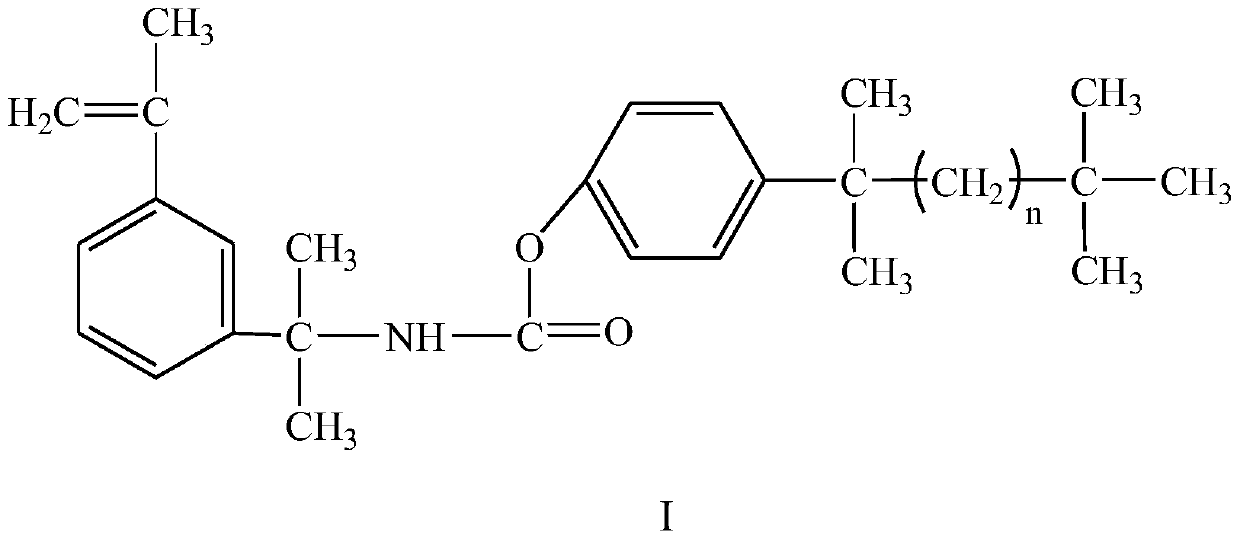

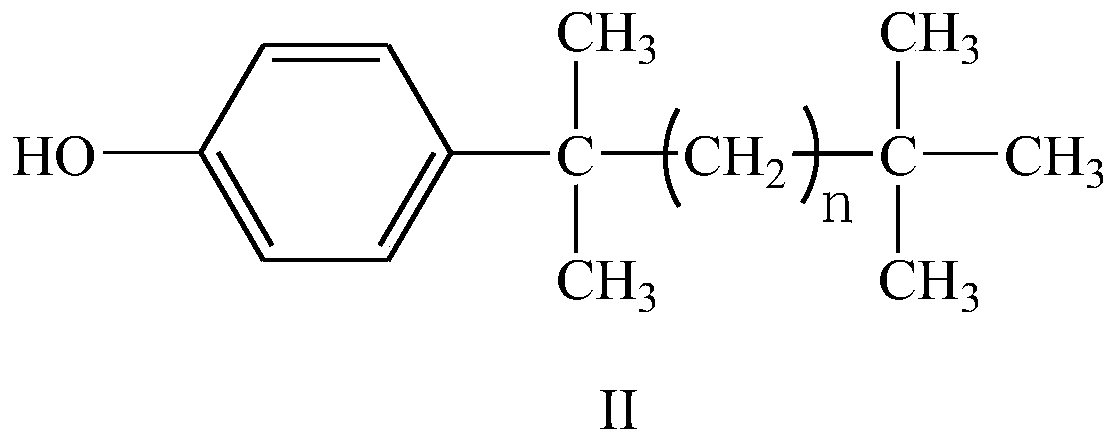

[0047] Preparation of Biphenyl Hydrophobic Monomer (n=1)

[0048] Add 600g acetone and 20.63g p-tertoctylphenol in a dry three-necked flask with stirrer, condenser and dropping funnel, add 21.13g of 3-isopropenyl-dimethylbenzyl isocyanate in the dropping funnel, start Stir until the p-tetylphenol in the flask is fully dissolved. The water bath was heated to 53° C., and a vacuum was applied for 2 hours while heating to remove moisture in the flask. Then add 0.0169g of dibutyltin dilaurate under the protection of nitrogen, and drop the 3-isopropenyl-dimethylbenzyl isocyanate in the dropping funnel into the three-necked flask, react for 7.5 hours, and distill under reduced pressure to remove Acetone, that is, the crude product of the monomer is obtained. The crude product was rinsed with chloroform three times, placed in an oven at 65°C and dried to constant weight to obtain the target product.

Embodiment 2

[0050] Preparation of Biphenyl Hydrophobic Monomer (n=4)

[0051] Add 600g toluene and 24.84g 4-(1,1,6,6-tetramethylheptyl)phenol into a dry three-necked flask with a stirrer, condenser and dropping funnel, add 21.13g of 3 -Isopropenyl-dimethylbenzyl isocyanate, start stirring until the 4-(1,1,6,6-tetramethylheptyl)phenol in the flask is fully dissolved. The water bath was heated to 79°C, and a vacuum was applied for 2 hours while heating to remove moisture in the flask. Then add 0.0169g dibutyltin dilaurate under the protection of nitrogen, and drop the 3-isopropenyl-dimethylbenzyl isocyanate in the dropping funnel into the three-necked flask, react for 10 hours, and distill under reduced pressure to remove Toluene, the crude product of the monomer is obtained. The crude product was rinsed with chloroform three times, placed in an oven at 65°C and dried to constant weight to obtain the target product.

Embodiment 3

[0053] Preparation of plugging gel (n=1)

[0054] Add 14.22g of acrylamide, 28.82g of acrylic acid, 31.09g of 2-acrylamido-2-methylpropanesulfonic acid, 6.17g of N,N-methylenebisacrylamide and 1500g of water into the reactor, stirring until completely dissolve. The pH of the solution was adjusted to 8.5 with a NaOH solution having a mass concentration of 50.0%. Add 4.08g of the diphenyl hydrophobic monomer prepared in Example 1 and 48.0g of sodium octadecyl sulfate under stirring conditions, continue to stir, solubilize the hydrophobic monomer in the sodium octadecyl sulfate micelles, and then pass nitrogen 60 minutes to remove dissolved oxygen in the solution. Add 1.0g K 2 S 2 o 8 , and then continue to pass nitrogen and heat up to the predetermined reaction temperature of 40 ° C, and react for 12 hours to obtain a gelatinous product. Wash with absolute ethanol, pulverize and dry to obtain the target product.

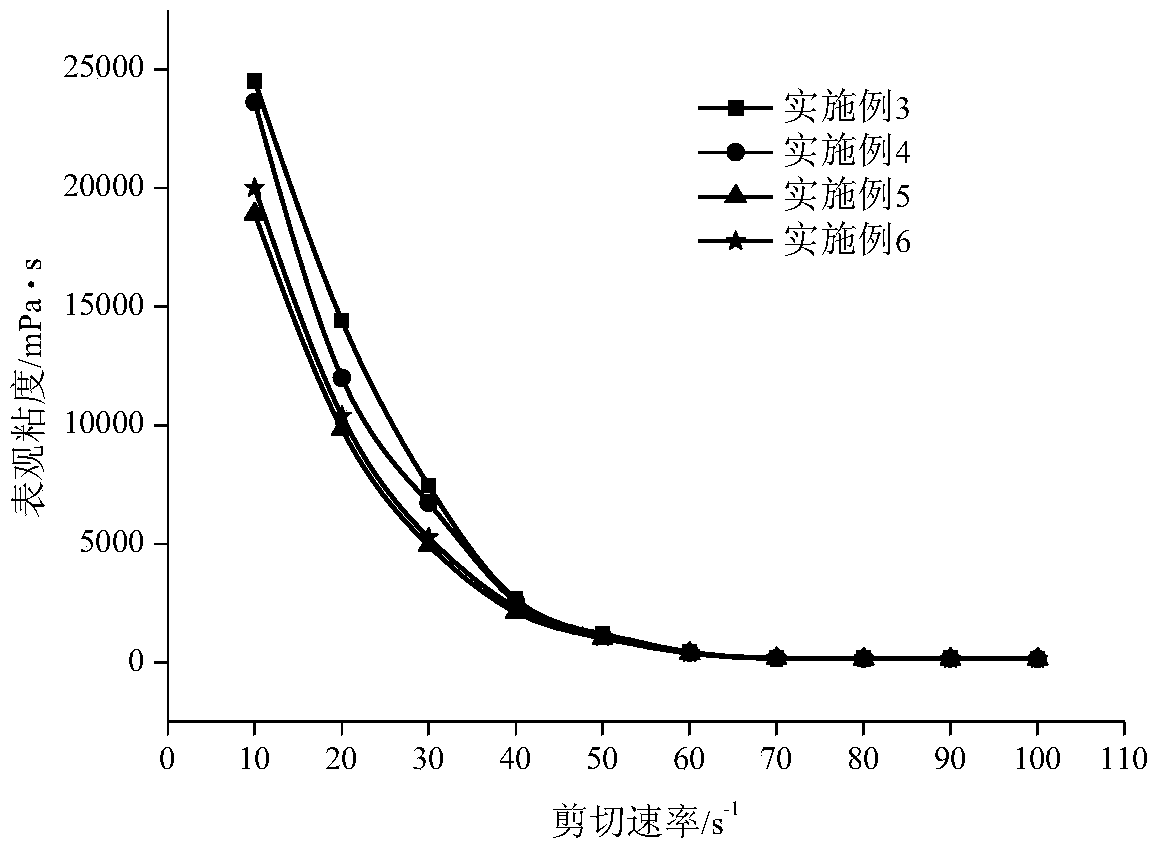

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com