Functionalized polydopamine derived carbon layer coated carbon substrate preparation method and application

A technology of polydopamine and coated carbon, which is applied in the manufacture of hybrid/electric double-layer capacitors, electrical components, battery electrodes, etc., can solve the problem of inability to achieve uniform loading of high active materials, full exposure of electrochemical active sites, poor structural stability, Problems such as agglomeration and shedding, to achieve excellent electrochemical activity, stable structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

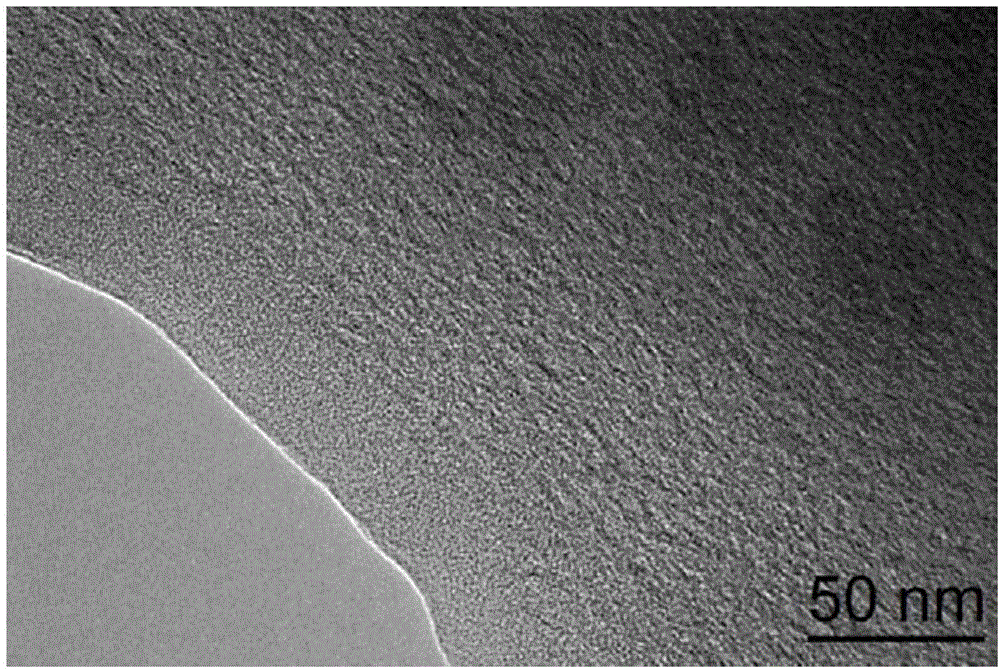

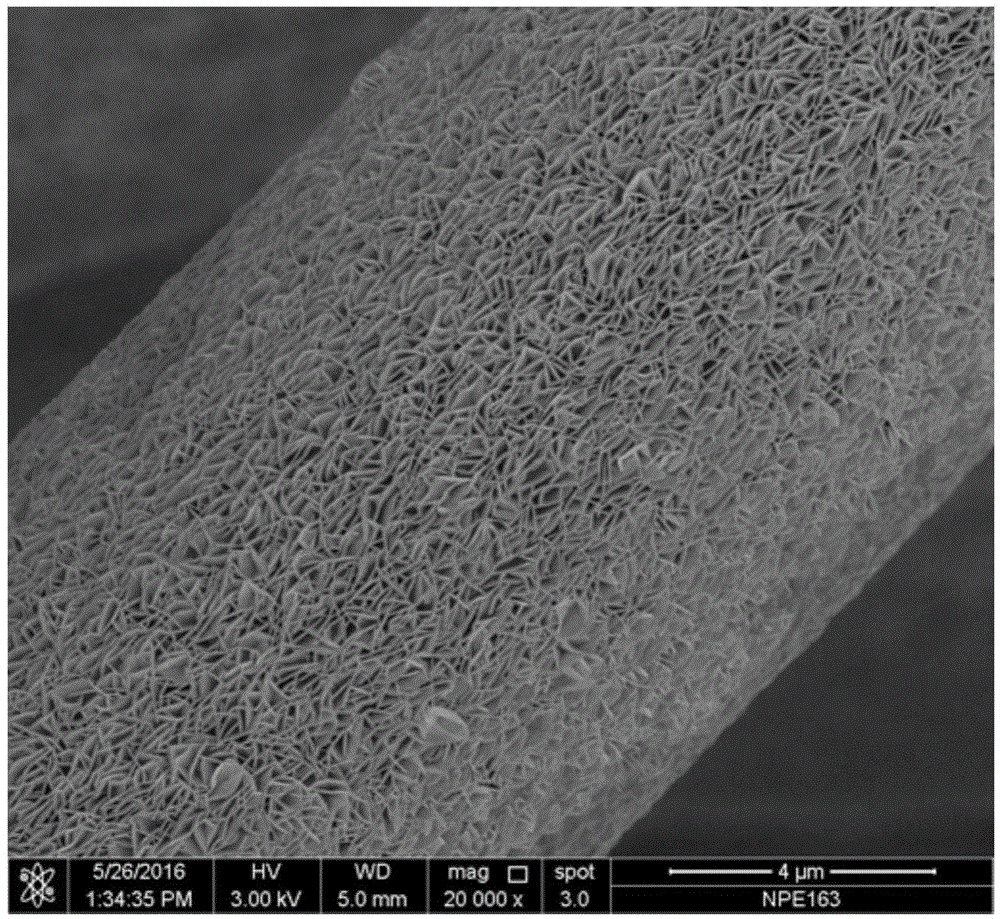

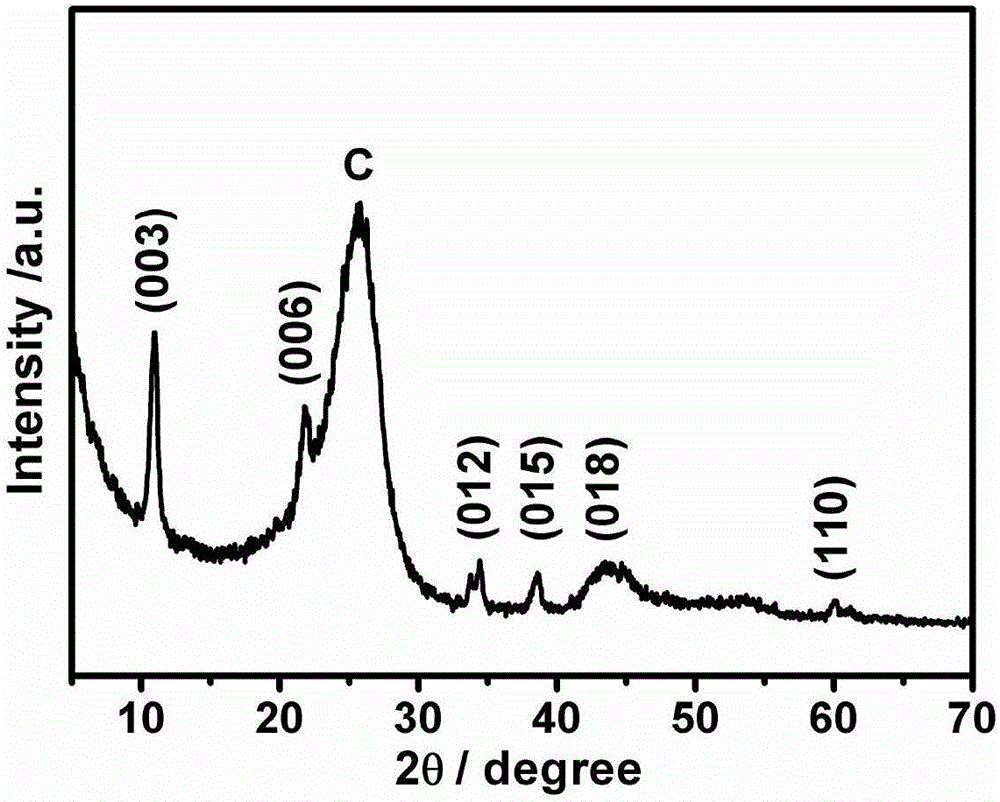

[0019] Weigh 200 mg of Tris, add it to 100 mL of deionized water, and then dropwise add dilute hydrochloric acid with a concentration of 0.1 mol / L to adjust the pH to 8.5. After stirring for 16 min, immerse the carbon cloth into the solution, then add 200 mg of dopamine hydrochloride was reacted at room temperature for 12 hours to obtain polydopamine-coated carbon cloth; then the obtained polydopamine-coated carbon cloth was carbonized at high temperature under nitrogen protection, and the temperature was increased from room temperature at a heating rate of 5 °C / min. The temperature was raised to 800°C, kept at a constant temperature for 120 min, and cooled to room temperature to obtain a polydopamine-derived carbon layer-coated carbon cloth; and then immersed the obtained polydopamine-derived carbon layer-coated carbon cloth into 80 mL of a bimetallic salt solution, in which hexahydrate The concentration of nickel nitrate is 0.03mol / L, the concentration of cobalt nitrate hexah...

Embodiment 2

[0021] Weigh 180 mg of Tris, add it to 60 mL of deionized water, add 0.1 mol / L of dilute hydrochloric acid dropwise to adjust the pH to 8.5, stir for 18 min, and immerse the carbon cloth into the solution, then add 180 mg of Dopamine hydrochloride was reacted at room temperature for 24 hours to obtain polydopamine-coated carbon cloth; then the obtained polydopamine-coated carbon cloth was carbonized at high temperature under nitrogen protection, and the temperature increased from room temperature to 10 °C / min. 700 ° C, constant temperature for 90 min, and cooling to room temperature to obtain polydopamine-derived carbon layer-coated carbon cloth. Then, the obtained polydopamine-derived carbon layer-coated carbon cloth was dipped into 60 mL of a bimetallic salt solution, wherein the concentration of nickel nitrate hexahydrate was 0.02 mol / L, and the concentration of cobalt nitrate hexahydrate was 0.01 mol / L. The concentration of cetyltrimethylammonium bromide was 0.03 mol / L, th...

Embodiment 3

[0023] Weigh 350 mg of tris, add it to 140 mL of deionized water, then add 0.1 mol / L of dilute hydrochloric acid dropwise to adjust the pH to 8.5, stir for 30 min, and immerse the graphite paper into the solution, then add 280 mg of Dopamine hydrochloride was reacted at room temperature for 36 hours to obtain polydopamine-coated graphite paper; then the obtained polydopamine-coated graphite paper was carbonized at high temperature under argon protection, and the temperature was increased from room temperature at a heating rate of 8 °C / min. to 900° C., constant temperature for 90 min, and cooling to room temperature to obtain polydopamine-derived carbon layer-coated graphite paper. The obtained polydopamine-derived carbon layer-coated graphite paper was then dipped into 70 mL of a bimetallic salt solution, wherein the concentration of nickel nitrate hexahydrate was 0.04 mol / L, and the concentration of cobalt nitrate hexahydrate was 0.02 mol / L. The concentration of cetyltrimethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com