Double-toothed-connection-component inner double-walled pipe combination member and manufacturing method thereof

A technology of combining components and connectors, which is applied in the directions of building components, building structures, and elongated structural components for load-bearing. In order to improve the mechanical properties and durability, the construction technology is simple, and the structural integrity is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions claimed in the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

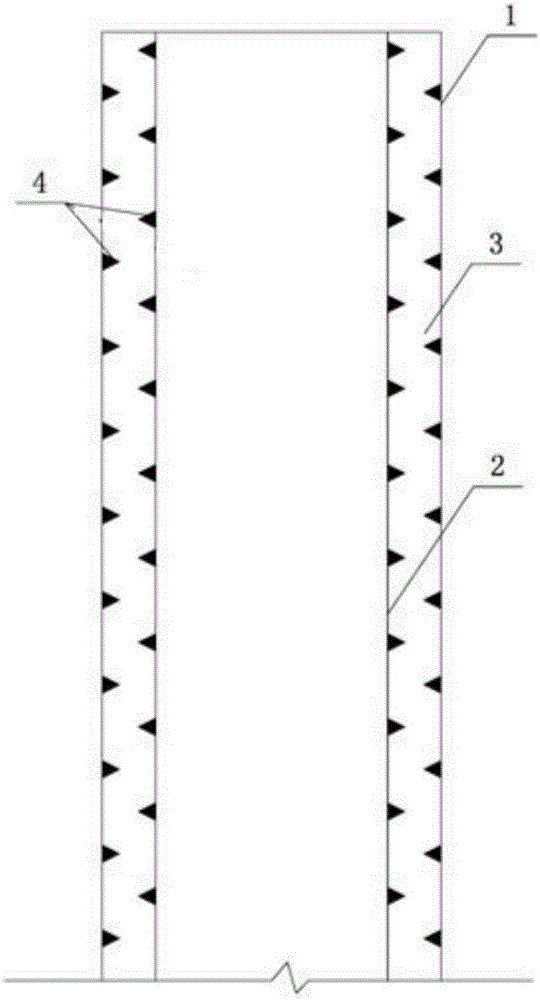

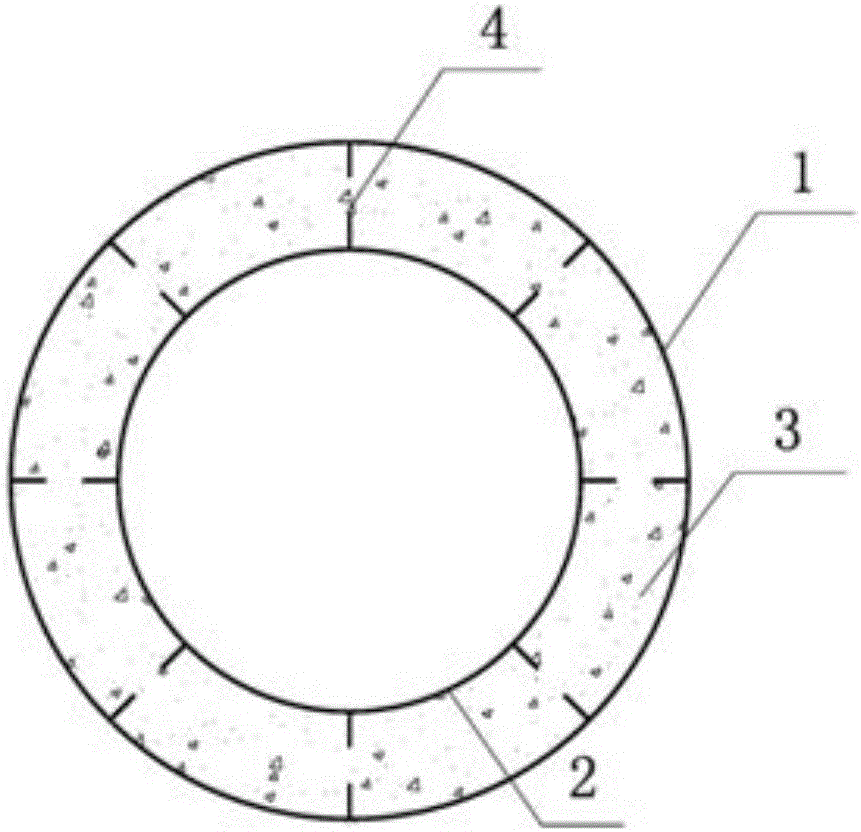

[0030] See attached figure 1 And attached figure 2 As shown, a double-threaded connector 4 double-walled pipe composite member in this embodiment includes an outer pipe 1 and an inner pipe 2, and concrete 3 is filled between the outer pipe 1 and the inner pipe 2, wherein the inner wall of the outer pipe 1 And the outer wall of the inner tube 2 is formed with a toothed connector 4 . In this embodiment, the double-wall pipe composite member is a hollow structure, that is, the interior of the inner pipe 2 is hollow. In other embodiments, it can also be replaced with a solid structure according to actual needs, that is, the interior of the inner pipe 2 is also filled with concrete 3 . In this embodiment, the inner tube 2 is a round steel pipe, and the outer tube 1 is an FPR tube. In other embodiments, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com