Production Methods of Flame-retardant Antistatic Blended Yarn and Its Use

A flame retardant, antistatic, and production method technology, applied in textiles, papermaking, yarn, etc., can solve the problems of uneven weight in the drawing process, difficulty in spinning, difficult opening, etc., and achieve excellent wearing performance, moisture absorption and breathability, Excellent antistatic performance, natural and soft hand effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

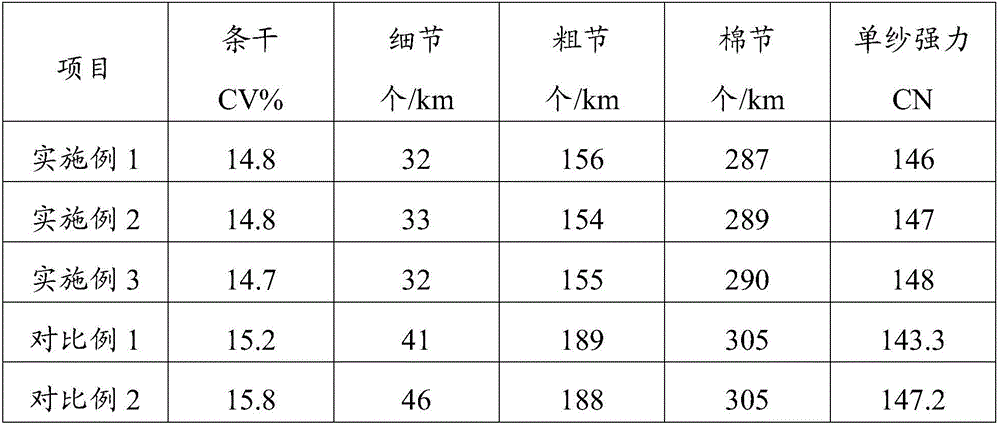

Examples

Embodiment 1

[0031] A flame-retardant antistatic blended yarn produced through the following steps:

[0032] 1) Blending process

[0033] Because silicon-nitrogen flame-retardant regenerated cellulose fibers are difficult to open, in order to open the silicon-nitrogen flame-retardant regenerated cellulose fibers as much as possible, and to mix the three blended fibers as evenly as possible, the silicon-nitrogen flame-retardant Combustible regenerated cellulose fiber, flame-retardant acrylic fiber and white nylon conductive short fiber 301-051-XOS are mixed evenly at a ratio of 58:40:2 for the cleaning process.

[0034] 2) Cleaning process

[0035] The blended fibers are all regenerated fibers, free of impurities, and have good uniformity; the disadvantages of silicon nitrogen flame-retardant regenerated cellulose fibers are low dry breaking strength and difficult to open. On the basis of the traditional process, the process of A036B porcupine opener is reduced, which can protect the fibe...

Embodiment 2

[0050] The parameters of each process are consistent with those in Example 1, except that the weight ratio of silicon nitrogen-based flame-retardant regenerated cellulose fiber, flame-retardant acrylic fiber, and white nylon conductive staple fiber 301-051-XOS is 58:40:2.

Embodiment 3

[0052] The parameters of each process in Example 1 are the same, the difference is that the weight ratio of silicon nitrogen-based flame-retardant regenerated cellulose fiber, flame-retardant acrylic fiber, and white nylon conductive short fiber 301-051-XOS is 50:48:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry breaking strength | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com