Optical fiber connector and assembling method thereof

An optical fiber connector and assembly method technology, applied in the directions of light guides, optics, instruments, etc., can solve the problems that cannot be solved by pressing and regrinding, the ceramic end face and core wire are damaged, the ferrule ceramic surface is damaged, etc., and the structure is simple. , Solve the effect of unmanufacturable and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

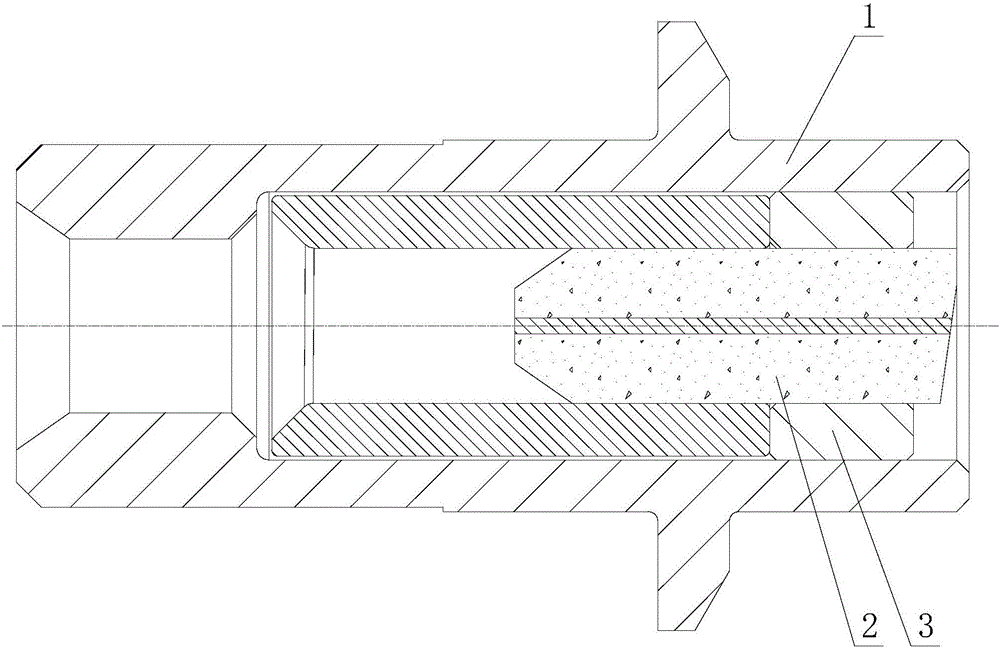

[0019] Such as figure 1 As shown, the optical fiber connector includes a metal sleeve 1 and a ceramic ferrule 2, a metal ring 3 is provided between the metal sleeve and the ceramic ferrule, and the metal ring is sleeved on the ceramic ferrule And located in the middle of the ceramic ferrule. The metal ring tightly fits with the ceramic ferrule. The end face of the ceramic ferrule is located inside the end face of the metal sleeve to protect the end face of the ceramic ferrule from damage.

[0020] The assembly method of the optical fiber connector described above includes step 1: grinding the end face of the ceramic ferrule, and pressing the ceramic ferrule into the metal ring; step 2: pressing the ground ceramic ferrule into the metal sleeve.

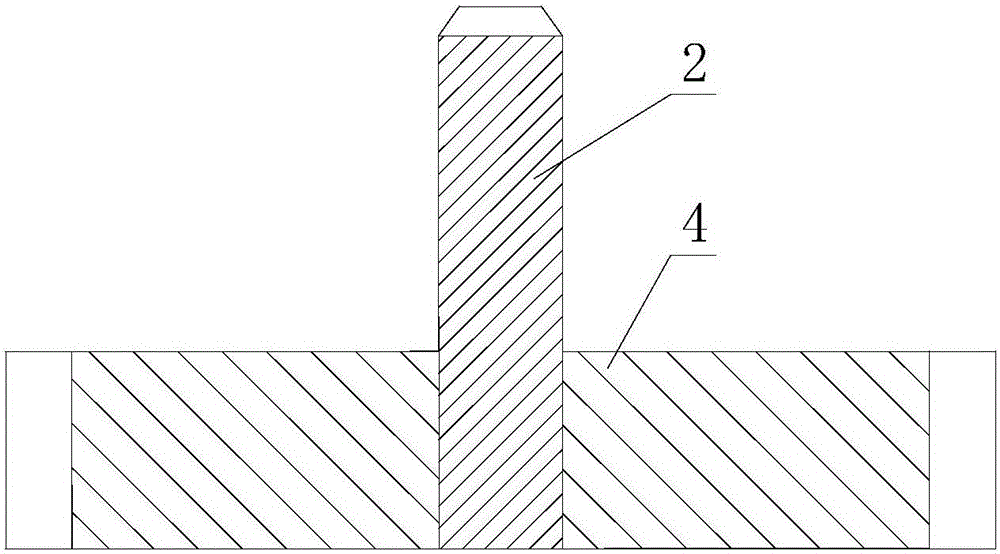

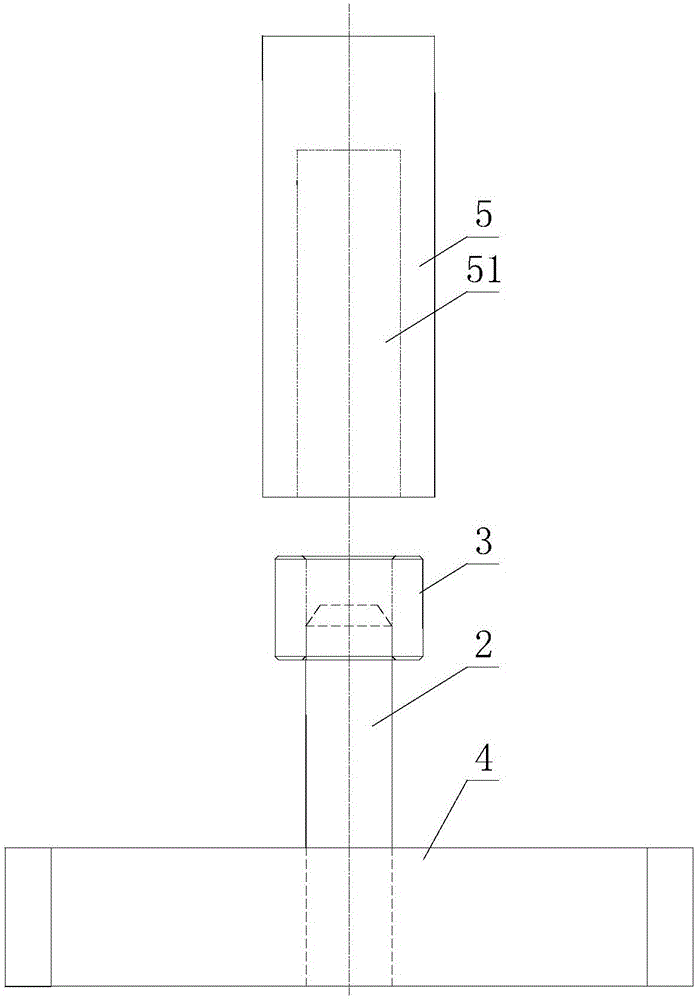

[0021] The first step includes the following steps: (1) grinding the end face of the ceramic ferrule; (2) embedding the ground ceramic ferrule into the bottom plate I4 (such as figure 2 shown); (3) Buckle the metal ring on the grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com