Three-clutch gearbox for loader

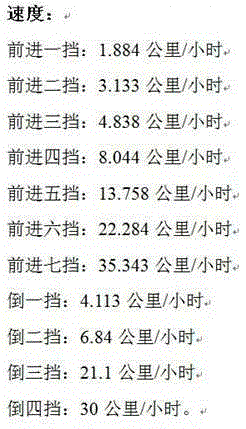

A three-clutch, gearbox technology, applied in vehicle gearboxes, mechanical equipment, transmission devices, etc., can solve problems such as reducing the service life of gearbox oil, low transmission efficiency of hydraulic torque converters, and affecting the working efficiency of engineering machines. Achieve low shovel loading speed, easy operation, and avoid engine stalling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and examples.

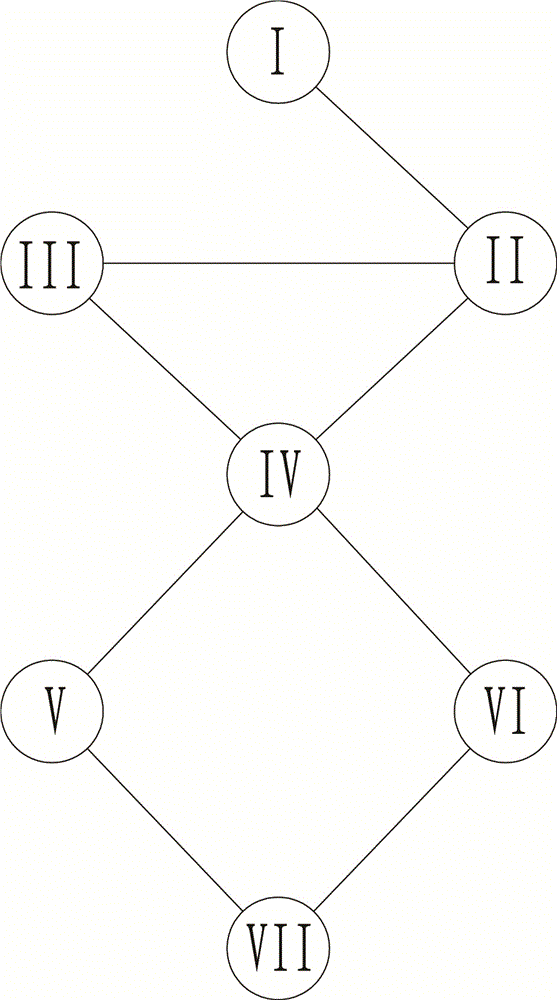

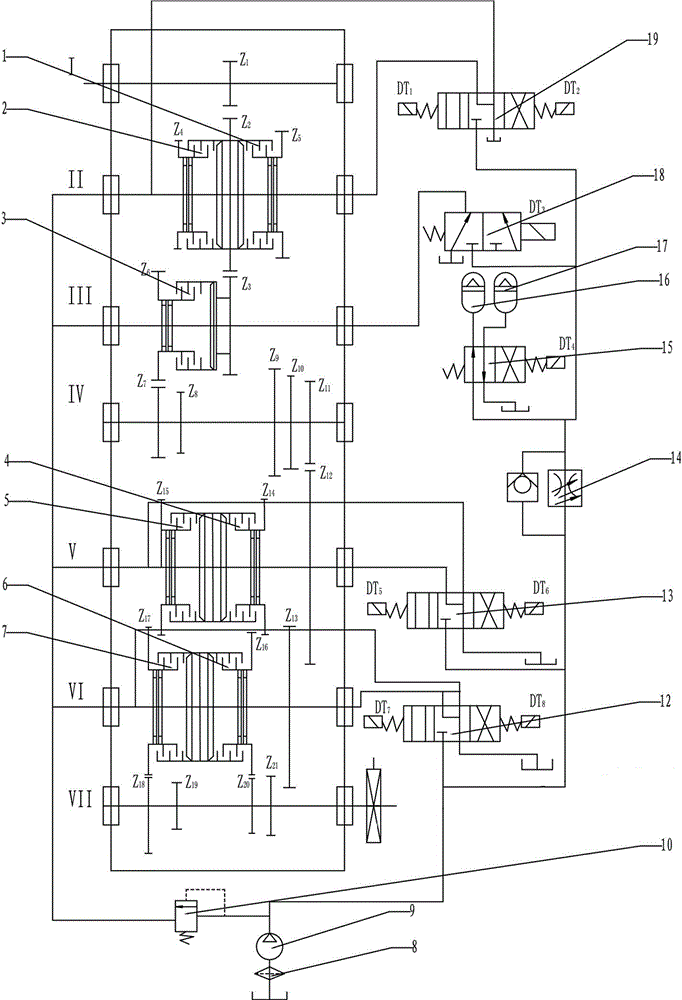

[0021] like figure 1 , 2 As shown, the present invention includes a box, and shafts I, II, III, IV, V, VI and VII are respectively installed in the box through bearings and are parallel to each other. Shaft I is the input shaft, the left end is used to connect with the engine, the right end is connected with the gear pump 9, and the Z1 gear is installed on the shaft I. The first wet clutch 1 and the second wet clutch 2 are installed on the shaft II, and there are lubricating oil passages leading from the left end of the shaft to the friction disc chambers of the first wet clutch 1 and the second wet clutch 2 respectively on the shaft II. There is also a control oil channel leading from the right end of the shaft to the piston chambers of the first wet clutch 1 and the second wet clutch 2 respectively. The third wet clutch 3 is installed on the shaft III...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com