Online three-stage eddy flow dehydration device of submarine pipeline

A technology for dehydration of submarine pipelines and cyclones, which is applied in the direction of cyclone devices, devices in which the axial direction of the cyclone can be reversed, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

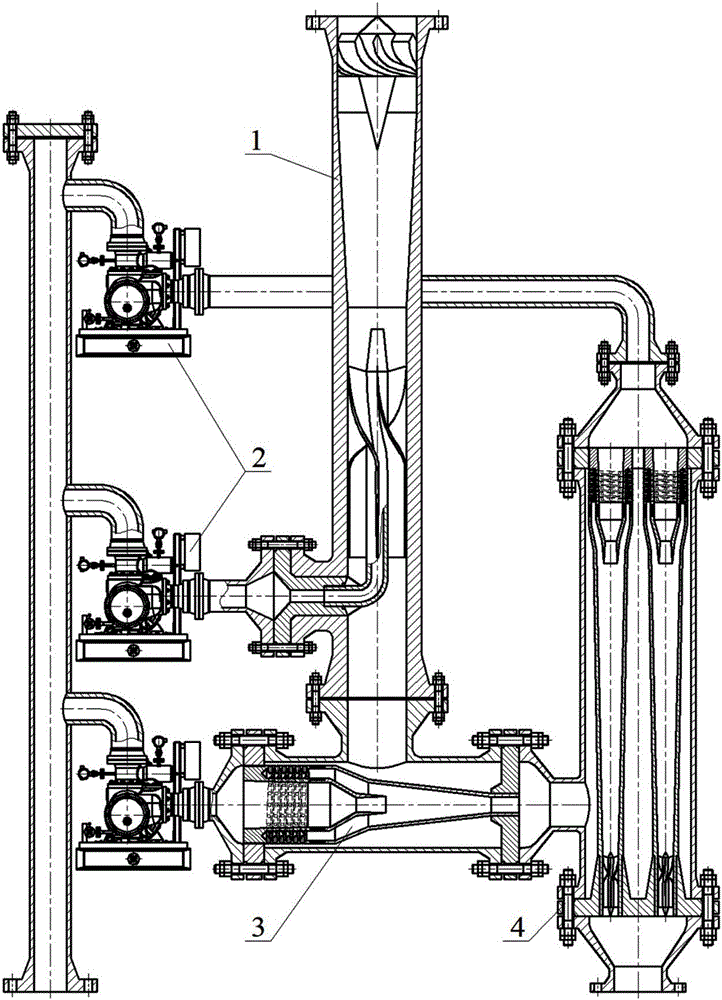

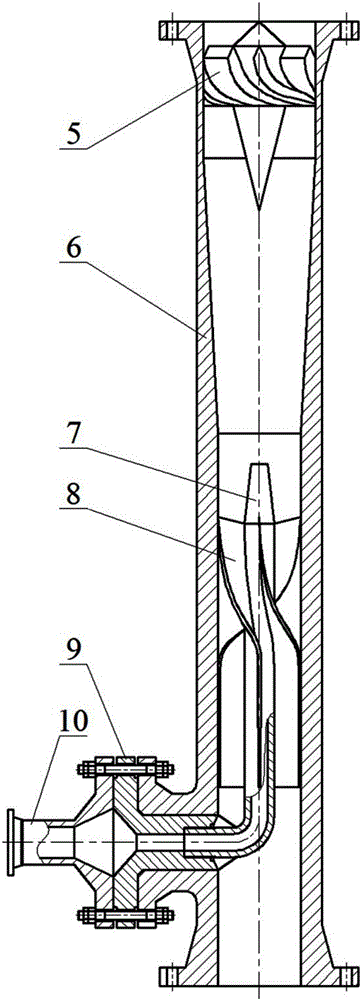

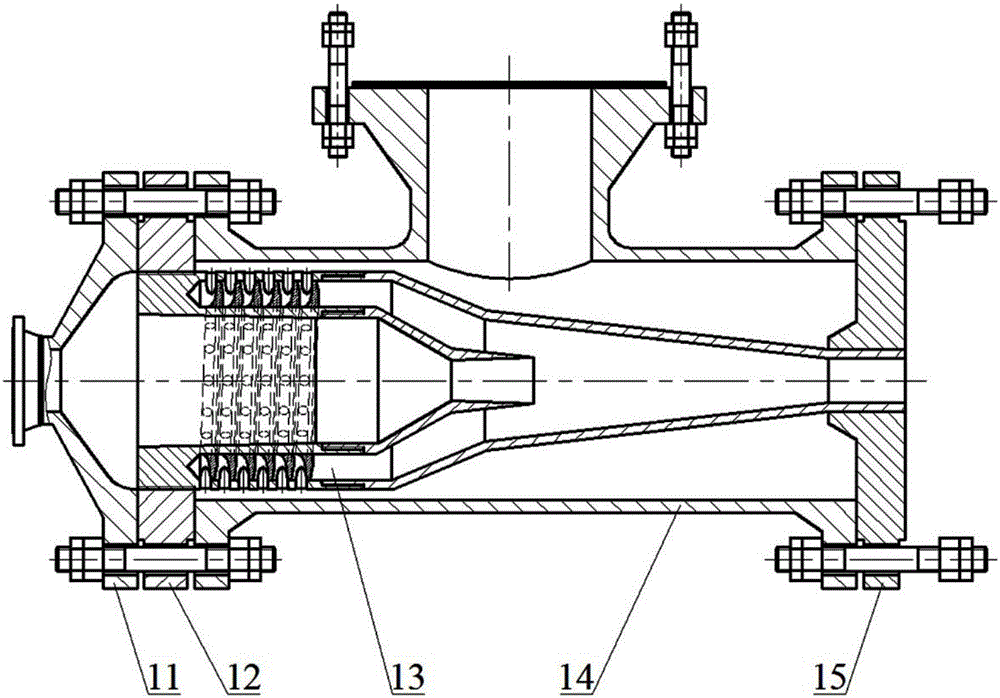

[0034] exist figure 1 Among them, the submarine pipeline online three-stage cyclone dehydration device is composed of the first-stage dehydrator 1, the second-stage dehydrator 3, the third-stage dehydrator 4 and the crude oil booster 2. The first-stage dehydration cylinder of the first-stage dehydrator 1 is connected to the wellhead underwater manifold through a jumper pipe and flange, and the third-stage drain pipe of the third-stage dehydrator 4 is connected to the water delivery manifold through a flange At the same time, the outgoing sea pipe of the crude oil booster 2 is connected with the seabed pipe through flanges, so that the dehydration device is organically combined with the underwater manifold and the seabed pipe, and the online installation of the seabed pipe can be realized. After the second-stage dehydrator 3 is connected with the first-stage dehydrator 1 and the third-stage dehydrator 4 respectively, the axes of the three are perpendicular to each other and pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com