Power module

A power module group, power module technology, applied in the output power conversion device, AC power input into DC power output, electrical components and other directions, can solve problems such as increasing power density, to increase power density, reduce costs, avoid uneven flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

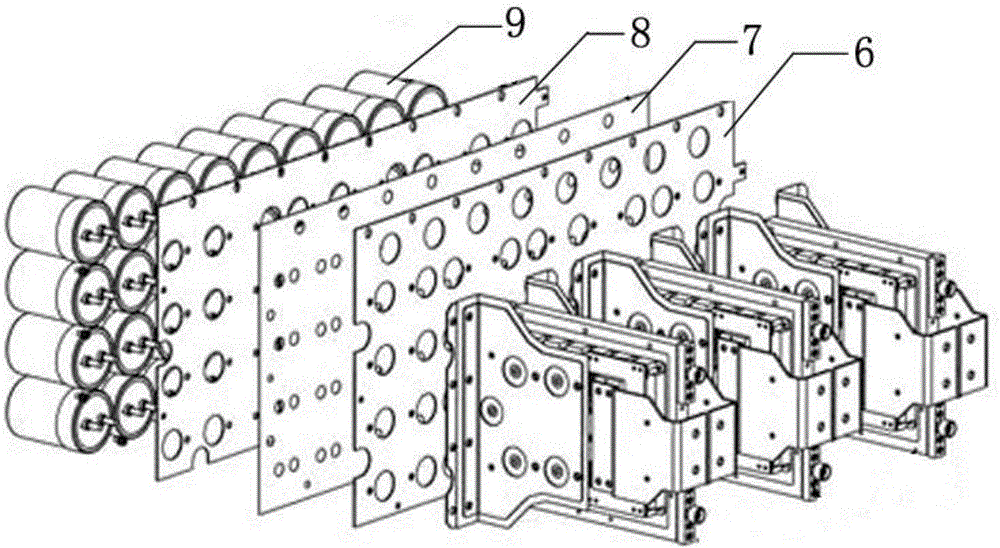

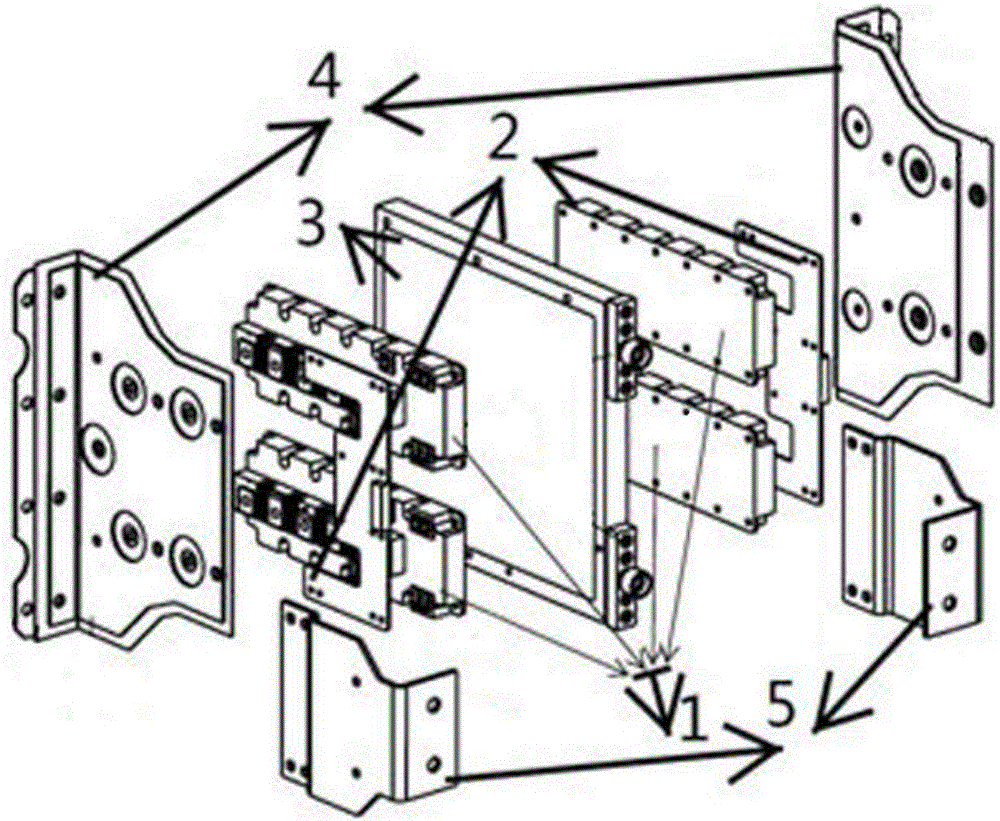

[0027] Embodiment 1: as Figures 1 to 3 As shown, the power module module involved in the present invention includes an IGBT power module and a capacitor module. The IGBT power module is composed of three IGBT power module structures arranged side by side. The capacitor module includes a capacitor group 9, a positive busbar copper bar 8, a middle Insulation layer 7 and negative busbar copper bar 6.

[0028] The IGBT power module structure includes an IGBT module group, an IGBT driver board 2, a heat sink 3 for the IGBT module, a DC busbar 4 connected to the IGBT module, and an AC copper busbar 5 for connecting the IGBT modules in parallel. The IGBT module group consists of two IGBT modules 1 connected in parallel and installed on the liquid cooling radiator 3. The IGBT module 1 can be a commonly used 1000A power module (such as the fourth-generation FF1000R17IE4 of Infineon in Germany, or it can be the same package size of the fifth generation FF1800R17IP5), it can also be ne...

Embodiment 2

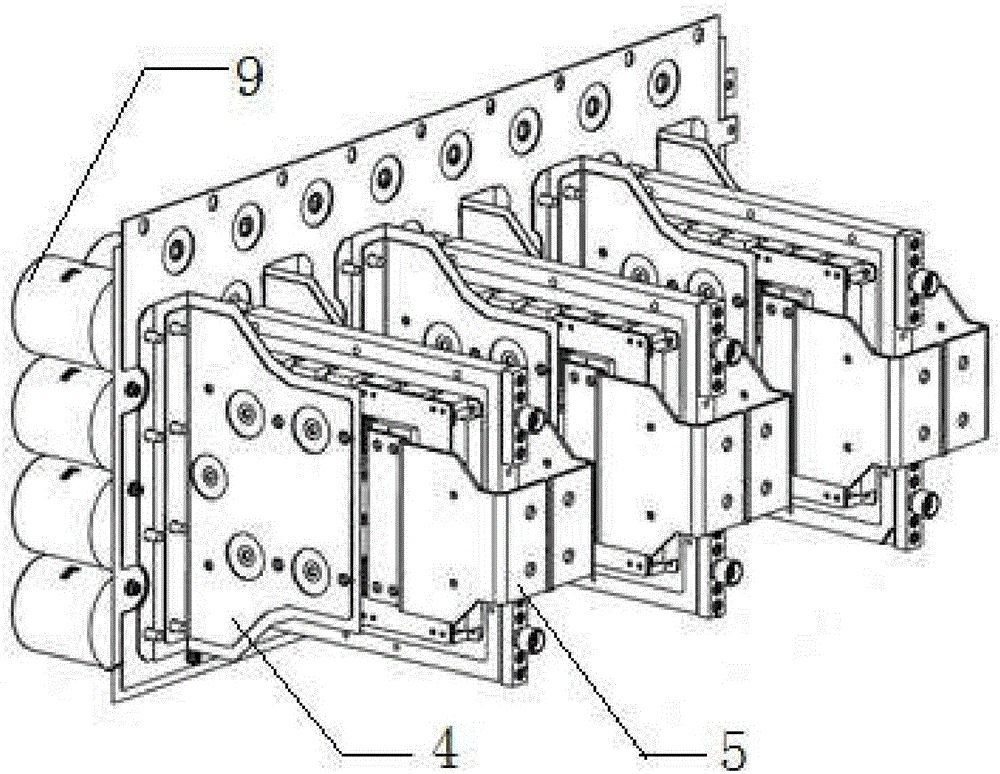

[0030] Embodiment 2: as Figure 4 As shown, the power module module involved in the present invention includes an IGBT power module and a capacitor module. The IGBT power module is composed of three IGBT power module structures arranged side by side. The capacitor module includes a capacitor group 9, a positive busbar copper bar 8, a middle Insulation layer 7 and negative busbar copper bar 6.

[0031]The IGBT power module structure includes an IGBT module group, an IGBT driver board 2, a heat sink 3 for the IGBT module, a DC busbar 4 connected to the IGBT module, and an AC copper busbar 5 for connecting the IGBT modules in parallel. The IGBT module group consists of two IGBT modules 1 connected in parallel and installed on the liquid cooling radiator 3. The IGBT module 1 can be a commonly used 1000A power module (such as the fourth-generation FF1000R17IE4 of Infineon in Germany, or it can be the same package size of the fifth generation FF1800R17IP5), it can also be new silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com