Elastomer composition used for water washing flexographic plate, and water washing flexographic plate containing elastomer composition and having excellent press life and affinity for ink

A water-washing flexible and elastic body technology, which is applied in the field of letterpress printing, can solve the problems of printing durability and ink affinity of plate materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

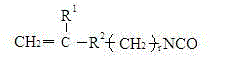

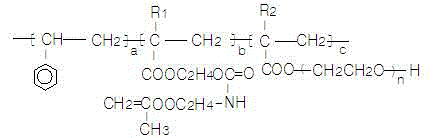

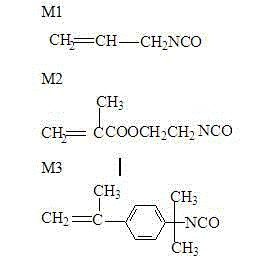

Method used

Image

Examples

Embodiment 1

[0076] Polymer A1: 77g, urethanized double bond polybutadiene (structure I, Mw=1000, Nippon Soda) 10g, 1,6-hexanediol diacrylate (Tianjiao) 2g, hydroxyethyl methacrylate (Mitsubishi Rayon) 4g, dipentaerythritol triacrylate (Sartomer) 5g, initiator 651 (Jingjiang Hongtai Chemical Industry) 1g, Neozapon-red395 (BASF) 0.5g, 2,6-Ditert-butyl p-cresol ( Nanjing Jiulong Chemical Industry) 0.1g, tertiary alkyl ethoxylamine (Liancarb Chemical) 0.1g, Tween 20 (Foshan Keqi Chemical Industry) 0.3g.

[0077] Plate performance: washing rating: 3 stars; ink affinity index: 10; 125lpi dot reduction: 2%-98%; independent dot: 0.2mm; independent line: 0.1mm, printing times: 420,000.

Embodiment 2

[0079]Polymer A2: 45g, urethanized double bond polybutadiene (structure II, Mw=5000, Zibo Qilong) 30g, 1,6-hexanediol diacrylate (Tianjiao) 12g, hydroxyethyl methacrylate (Mitsubishi Rayon) 5g, dipentaerythritol triacrylate (Sartomer) 13g, initiator 651 (Jingjiang Hongtai Chemical Industry) 5g, Neozapon-red395 (BASF) 2g, 2,6-Ditert-butyl p-cresol (Nanjing Jiulong Chemical Industry) 1g, tertiary alkyl ethoxy amine (Liancarb Chemical) 1g, Tween 20 (Foshan Deke Gas Chemical) 1g.

[0080] Plate performance: washing rating: 5 stars; ink affinity index: 7; 122lpi dot reduction: 2%-98%; independent dot: 0.2mm; independent line: 0.1mm, printing times: 280,000.

Embodiment 3

[0082] Polymer A3: 76g, urethanized double bond polybutadiene (structure III, Mw=1500, Nippon Soda) 5g, urethanized double bond polybutadiene (structure I, Mw=2000, Nippon Soda) 5g, 1,6-hexanediol diacrylate (Tianjiao) 2g, hydroxyethyl methacrylate (Mitsubishi Rayon) 5g, Satomer399 (Sartomer) 1g, initiator 651 (Jingjiang Hongtai Chemical) 1g, Neozapon- Red395 (BASF) 2g, 2,6-di-tert-butyl-p-cresol (Nanjing Jiulong Chemical Industry) 1g, tertiary alkyl ethoxyamine (Liancarb Chemical) 1g, Tween 20 (Foshan Deke Gas Chemical) 1g.

[0083] Plate performance: washing rating: 4 stars; 125lpi dot reduction: 2%-98%; independent dot: 0.2mm; independent line 0.1mm, printing times: 300,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com