Automatic oxygen control/corrosion device and method in high temperature lead and bismuth melt

A corrosion device, lead-bismuth technology, applied in weather resistance/light resistance/corrosion resistance, temperature control, measuring devices, etc., can solve problems such as low degree of automation, harsh operation and maintenance requirements, and poor device conditions, so as to improve efficiency and guarantee The effect of safe operation and intuitive position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

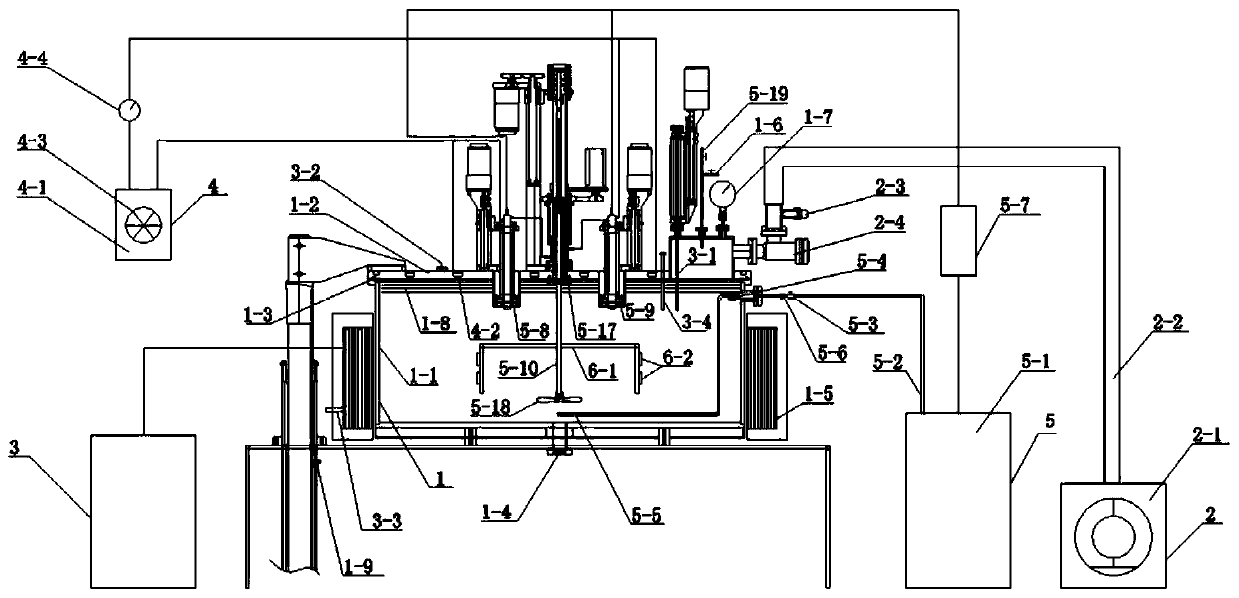

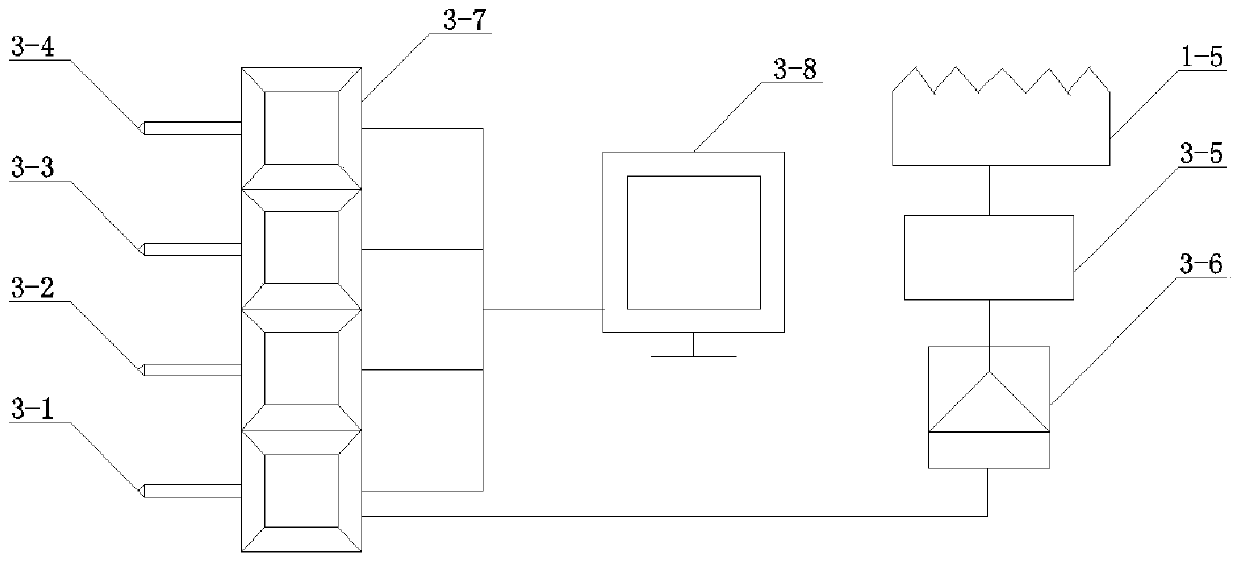

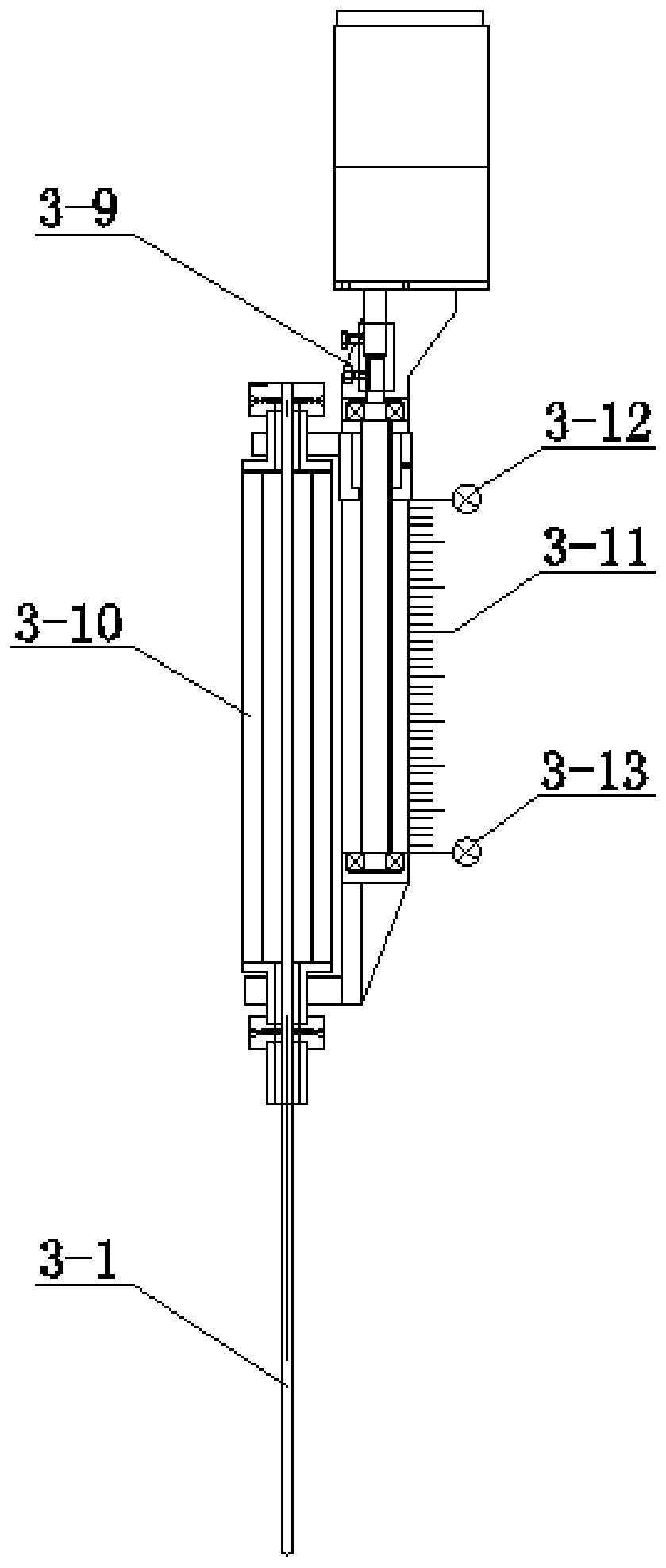

[0048] Example 1: see figure 1 , an automatic oxygen control / corrosion device in a high-temperature lead-bismuth melt, comprising a storage tank 1, on which a vacuum system 2, a temperature control system 3, a cooling system 4, an oxygen concentration control system 5, Sample corrosion experiment system 6 and automatic control and data processing system 7.

[0049] The storage tank 1 is a cylindrical high-vacuum airtight container, and the upper cover 1-2 is provided on the tank body 1-1, and the upper cover 1-2 and the tank body 1-1 are sealed with a thinner aluminum wire Circle 1-3, a semi-open tubular muffle furnace external heater 1-5 is provided on the side of the tank body 1-1, and the outside of the furnace body is covered with heat insulating material to ensure that the temperature of the heater continues at 1200°C The case temperature is below 40°C. The bottom of the tank body 1-1 is provided with a high temperature resistant discharge valve 1-4, which facilitates t...

Embodiment 2

[0065] Example 2: see Figure 7 , an automatic oxygen control / corrosion method in a high-temperature lead-bismuth melt, its main feature is that the steps are:

[0066] (a) Open the upper cover of the storage tank, load the lead-bismuth ingot, close the upper cover and seal it;

[0067] (b) Start the vacuum system, and use the vacuum cascade pump group to pump the vacuum in the storage tank to 1×10 -2 Pa;

[0068] (c) Close the vacuum system, and use the air inlet line of the upper cover to fill the tank with high-purity Ar gas;

[0069] (d) Repeat steps (b) and (c) 2-3 times, rinse the storage tank repeatedly, and finally keep the vacuum at 1×10 -2 Pa;

[0070] (e) Start the software and hardware of the temperature control system, cooling system, oxygen concentration control system, sample corrosion experiment system, and automatic control and data processing system;

[0071] (f) Select the oxygen probe calibration, oxygen concentration control or sample corrosion experi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com