Condensed water recycling heat exchanger for air conditioner

A heat exchanger and condensed water technology, applied in indirect heat exchangers, condensed water prevention, heat exchanger types, etc., can solve the problem of insufficient utilization of condensed water, etc., to facilitate promotion, improve performance coefficient, and facilitate mass production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

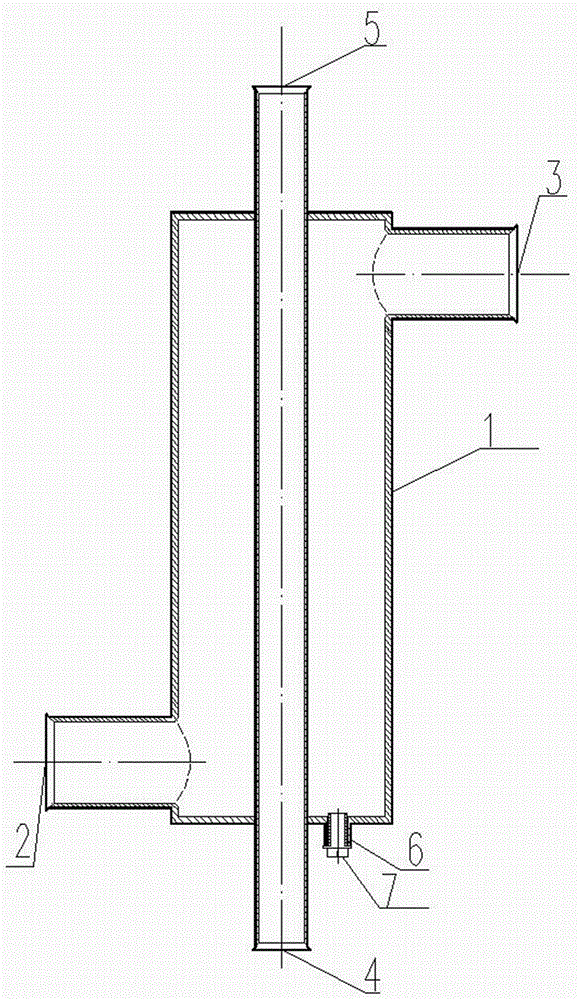

[0017] The present invention will be further described below in conjunction with accompanying drawing:

[0018] see figure 1 , a heat exchanger for reusing condensed water for air conditioning, comprising seven parts: a cooling heat exchanger, a condensed water inlet, a condensed water outlet, a refrigerant inlet, a refrigerant outlet, a drain pipe, and a drain plug. The heat exchanger is installed at the outlet of the compressor. The cooling heat exchanger, the inlet and outlet of condensed water, and the inlet and outlet of refrigerant are all made of copper tubes. The copper pipes of the compressor and the condenser are connected by flared sodium. During the installation process, the condensed water of the air conditioner is reused. When the heat exchanger and the equipment are manufactured at the same time, the copper pipe of the cooling heat exchanger is connected with the copper The tubes are connected by welding.

[0019] During use, after the condensed water of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com