Synthetic fiber treatment agent and use of same

A synthetic fiber and synthetic fiber filament technology, which is applied in the manufacture of false-twisted processed yarn and the field of synthetic fiber filament yarn, can solve the problems of no packaging appearance and unwinding treatment agent, and achieve excellent packaging appearance and unwinding property Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

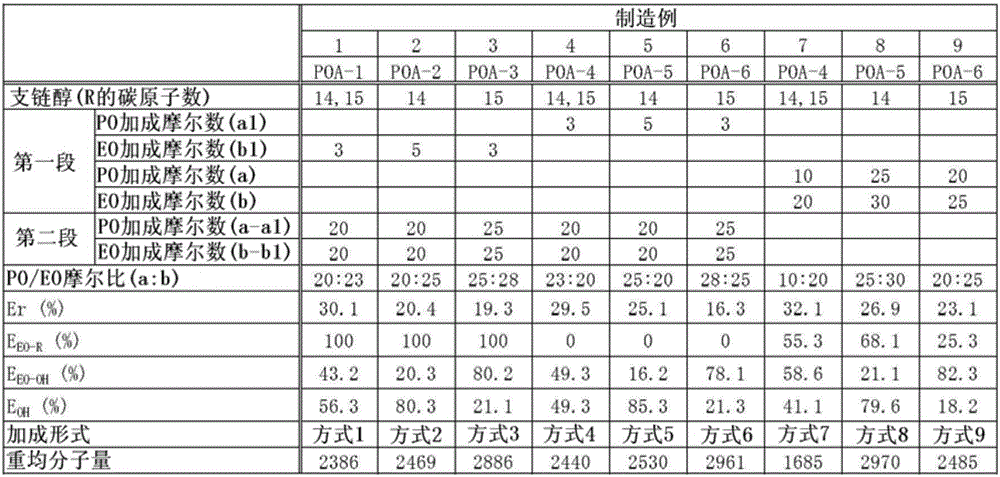

manufacture example 1

[0203] In the 3L autoclave that can be stirred, can be adjusted in temperature, and has an alkylene oxide feed box, a nitrogen supply pipe, and a pressure regulating valve, drop 221g of C as alcohol. 14-15 Branched chain alcohol, 3.5 g caustic potash as base catalyst. After replacing the inside of the autoclave with nitrogen, a dehydration operation was performed at 100 to 110° C. for 1 hour while stirring. Then, at a desired molar ratio, under a gauge pressure of 0.0-0.4MPa and a reaction temperature of 140-150°C, 132g of ethylene oxide is put in as the first stage, and a mixture of 1160g of propylene oxide and 880g of ethylene oxide is put in as the second stage. In the second stage, the addition polymerization reaction was carried out for about 15 hours. Thereafter, the obtained polyoxyalkylene alkyl ether was neutralized with 5.3 g of lactic acid, and recovered. Thus, polyoxyalkylene alkyl ether (POA-1) was obtained.

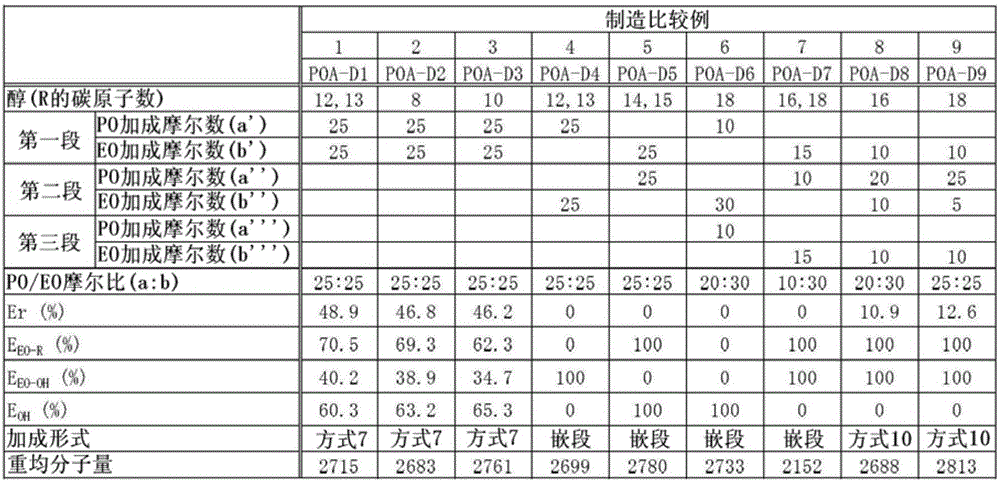

[0204] In Production Examples 2 to 9 and Production...

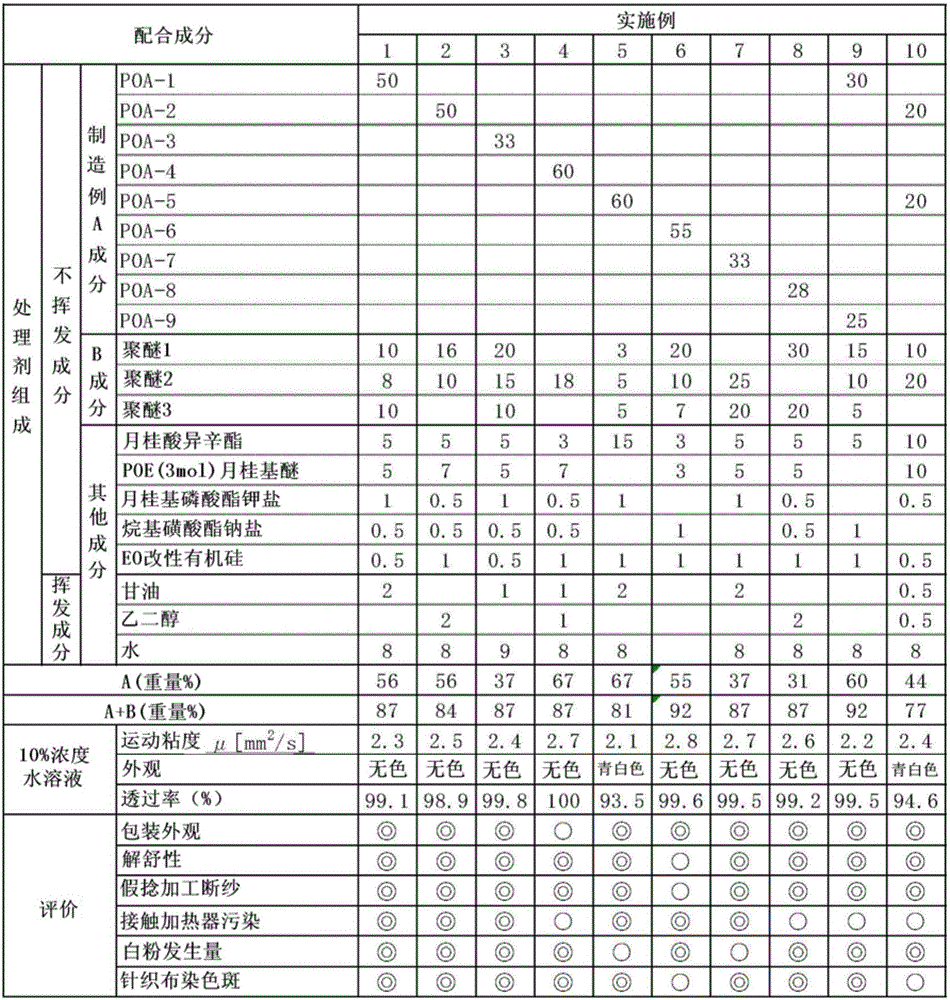

Embodiment 1~10、 comparative example 1~10

[0221] In Examples 1-10, the compounding component described in Table 3 and Table 4 was mixed and stirred, and the processing agent for synthetic fibers was prepared. In addition, the polyethers 1-3 in Table 3 and Table 4 are the following polyethers.

[0222] Polyether 1: PO / EO=50 / 50, weight average molecular weight 5000 random type

[0223] Polyether 2: PO / EO=25 / 75, weight average molecular weight 2000 random type

[0224] Polyether 3: PO / EO=50 / 50 polyoxyalkylene decyl ether, weight average molecular weight 800 random type

[0225] Next, water was added to the prepared synthetic fiber treatment agent to prepare an aqueous solution having a nonvolatile content of 10% by weight. Next, the polyethylene terephthalate full-dull yarn containing 2.5% of titanium oxide, which was spouted from the metal port by the extruder and cooled and solidified, was treated by using a metering pump device to supply oil to the nozzle. 130dtex / 72f (130デシテックス / 72フィラメメント) POY is spun into an aqueo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com