Horizontal type stirring sanding groove for producing efficient composite electroplated diamond wire and use method

A composite electroplating and diamond wire technology, applied in electrolytic components, electrolytic processes, electrolytic coatings, etc., can solve the problems of poor uniformity of diamond wire diameter, difficulty, and large circulation of mortar, and achieve uniform distribution of liquid flow field. Good dispersion effect, not easy to deposit and consolidate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

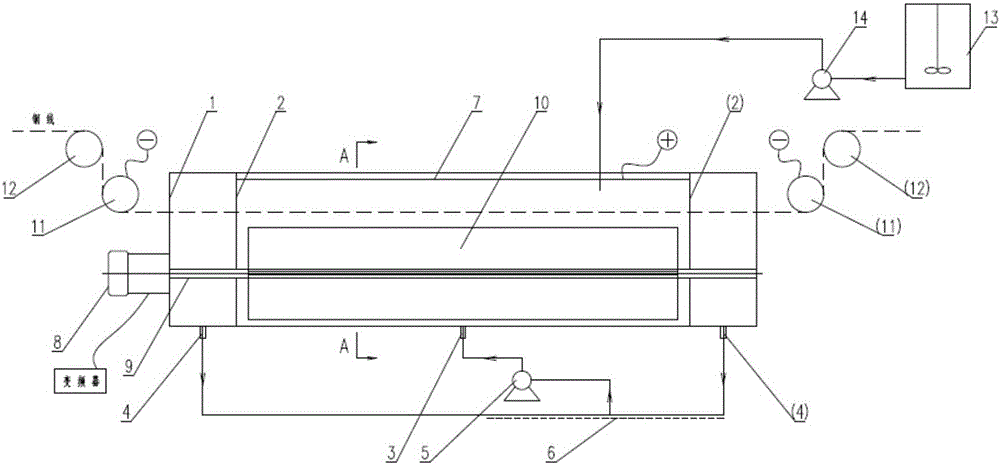

[0025] figure 1 Among them, a horizontal mixing and sanding tank for producing high-efficiency composite electroplating diamond wire, including a sanding tank body, overflow liquid circulation device, horizontal stirring device, steel wire transmission device, automatic feeding device, etc.

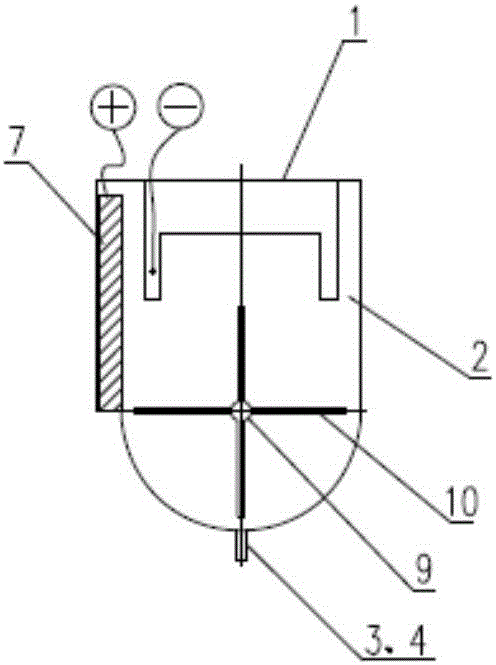

[0026] The upper sand tank body 1 includes three cavities, the middle cavity is the upper sand area at the arc-shaped bottom, and the two side cavities are overflow areas. figure 2 It can be seen from the figure that the middle partition of the three chambers is equipped with a liquid level adjustment plate 2. The vertical groove on the liquid level adjustment plate provides a routing channel for the steel wires. The vertical groove width and plate height of the adjustment plate can be adjusted. Liquid level in the sand zone;

[0027] The upper sand area is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com