cigs solar cell film production line

A solar cell and production line technology, applied in the manufacture of circuits, electrical components, final products, etc., can solve the problems that cannot overcome the difficulties of thin film technology, cannot reflect the advantages of low cost, and have not been fully manifested, and achieve small average film thickness and high speed. High energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail and completely below in conjunction with Examples and Comparative Examples.

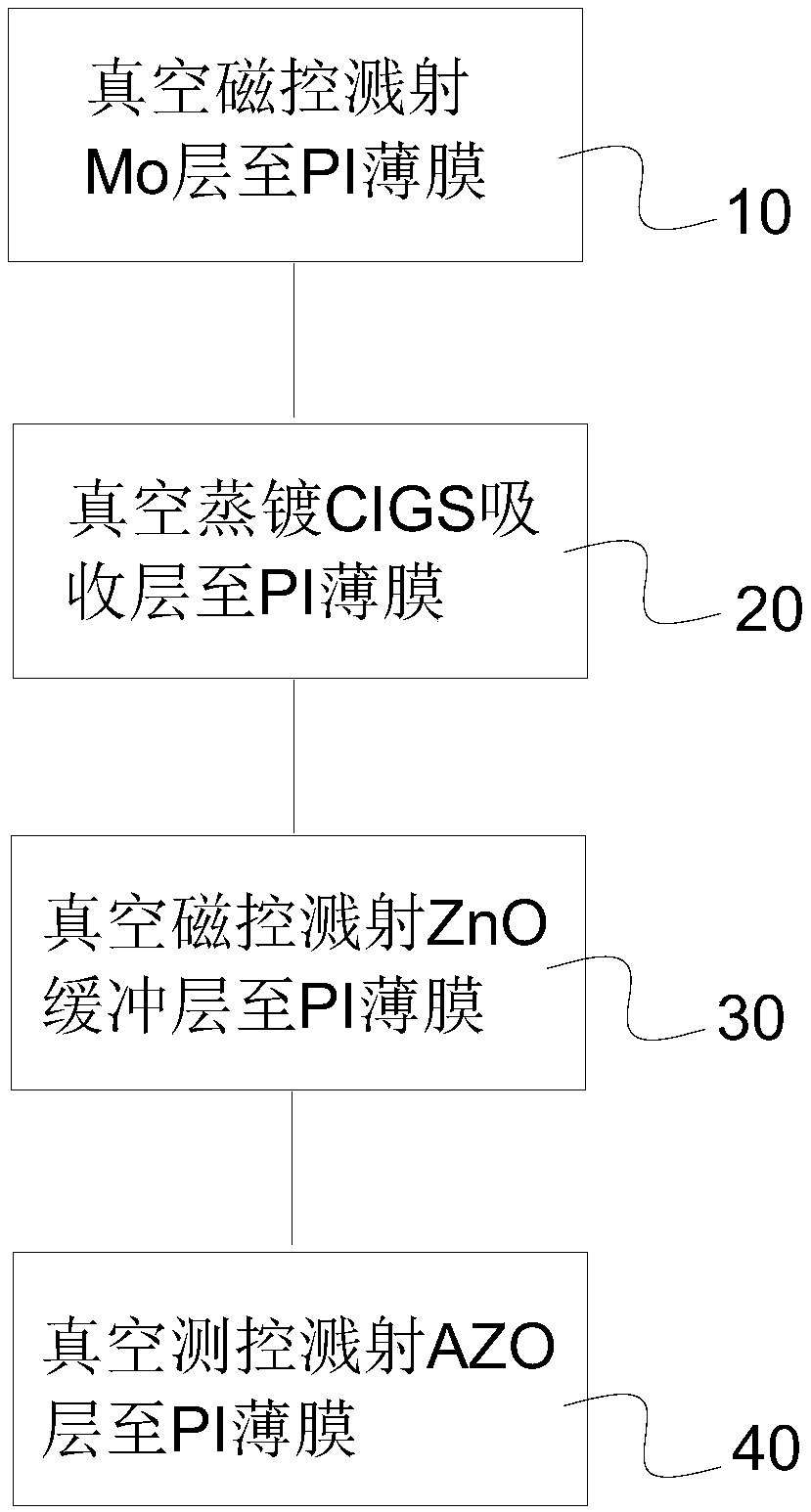

[0052] The CIGS solar cell thin film production line of the present invention is a vertical CIGS solar cell thin film production line, that is to say, in the production process, the thin film is produced in each step in a state perpendicular to the ground, and the vertical production line not only ensures that there is no impurity pollution in the coating process, And the non-contact with the equipment avoids the damage of the film surface, and also makes the coating more uniform during the coating process. Such as figure 1 As shown, the production line of the present invention comprises the following four process flow sections: the Mo sub-wire for sputtering metal molybdenum (Mo) onto the thin film; adopting the linear evaporation source of copper, indium, gallium to deposit in selenium environment Ring-shaped evaporation sub-lines fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com