Preparation method of antimicrobial hydrogel applied to surface of touch screen

A hydrogel and touch screen technology, applied in the field of antibacterial hydrogel preparation, can solve problems such as alcohol infiltration, eye hazard, damage, etc., and achieve the effects of preventing bacterial reproduction, reducing bacterial infection rate, and high-efficiency sterilization performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

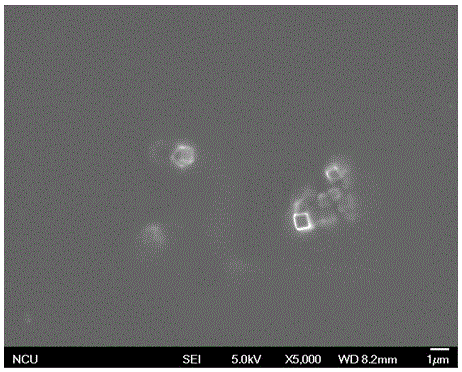

Image

Examples

Embodiment 1

[0032] A, the preparation of nano-cuprous oxide:

[0033] (a) Dissolve 2mmol of copper sulfate pentahydrate and 1mmol of EDTA (ethylenediaminetetraacetic acid) in 30mL of deionized water, and stir for 30 min;

[0034] (b) Heat the solution prepared in step A-a to 55°C, and add 25mL of 0.6M NaOH solution;

[0035] (c) After 40 min, add 0.5 g of C to the solution prepared in step A-b 6 h 6 o 2 (1,4-hydroquinone), and continue to stir for 1h;

[0036] (d) After the reaction in steps A-c, the solution is naturally cooled to room temperature, and then the precipitate is centrifuged, washed with deionized water and absolute ethanol respectively, and then dried to obtain nano-cuprous oxide;

[0037] B. Preparation of hydrogel:

[0038] (a) Dissolve 1 g of Carbomer 940 in 50 ml of deionized water and stir for 120 min;

[0039] (b) Heat the solution prepared in step B-a to 50°C, and continue to stir for 3h until the carbomer is completely swollen;

[0040] (c) Grinding 0.2 g of ...

Embodiment 2

[0047] A, the preparation of nano-cuprous oxide:

[0048] (a) Dissolve 2 mmol of copper sulfate pentahydrate and 1 mmol of EDTA (ethylenediaminetetraacetic acid) in 10 mL of deionized water, and stir for 2 min;

[0049] (b) Heat the solution prepared in step A-a to 30°C, and add 1mL of 0.1M NaOH solution;

[0050] (c) After 1 min, add 0.1 g of C to the solution prepared in step A-b 6 h 6 o 2 (1,4-hydroquinone), and continue stirring for 0.5-24h;

[0051] (d) After the reaction in steps A-c, the solution is naturally cooled to room temperature, and then the precipitate is centrifuged, washed with deionized water and absolute ethanol respectively, and then dried to obtain nano-cuprous oxide;

[0052] B. Preparation of hydrogel:

[0053] (a) Dissolve 1g of Carbomer 940 in 20ml of deionized water and stir for 3 minutes;

[0054] (b) Heat the solution prepared in step B-a to 30°C, and continue stirring for 4 min until the carbomer is completely swollen;

[0055] (c) Grinding 0...

Embodiment 3

[0062] A, the preparation of nano-cuprous oxide:

[0063] (a) Dissolve 2 mmol of copper sulfate pentahydrate and 1 mmol of EDTA (ethylenediaminetetraacetic acid) in 100 mL of deionized water, and stir for 200 min;

[0064] (b) Heat the solution prepared in step A-a to 90°C, and add 100mL of 2M NaOH solution;

[0065] (c) After 50 min, add 5 g of C to the solution prepared in step A-b 6 h 6 o 2 (1,4-hydroquinone), and continue stirring for 24h;

[0066] (d) After the reaction in steps A-c, the solution is naturally cooled to room temperature, and then the precipitate is centrifuged, washed with deionized water and absolute ethanol respectively, and then dried to obtain nano-cuprous oxide;

[0067] B. Preparation of hydrogel:

[0068] (a) Dissolve 1g of Carbomer 940 in 200ml of deionized water and stir for 300 minutes;

[0069] (b) Heat the solution prepared in step B-a to 30-90°C, and continue stirring for 400 min until the carbomer is completely swollen;

[0070] (c) Gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com