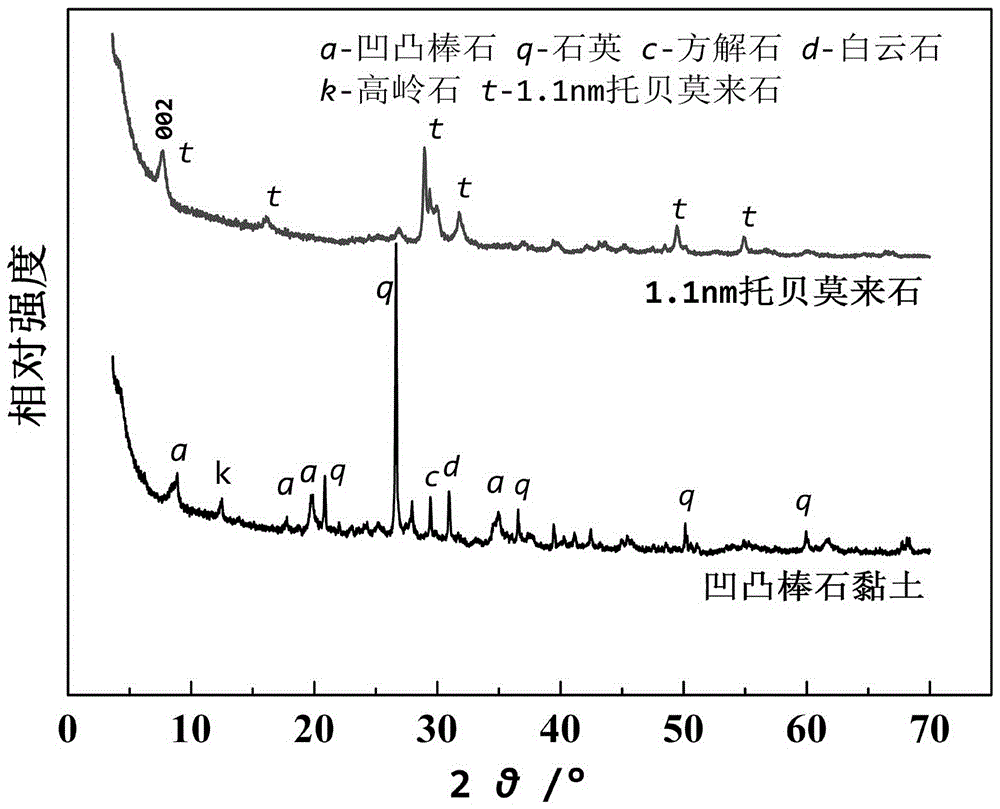

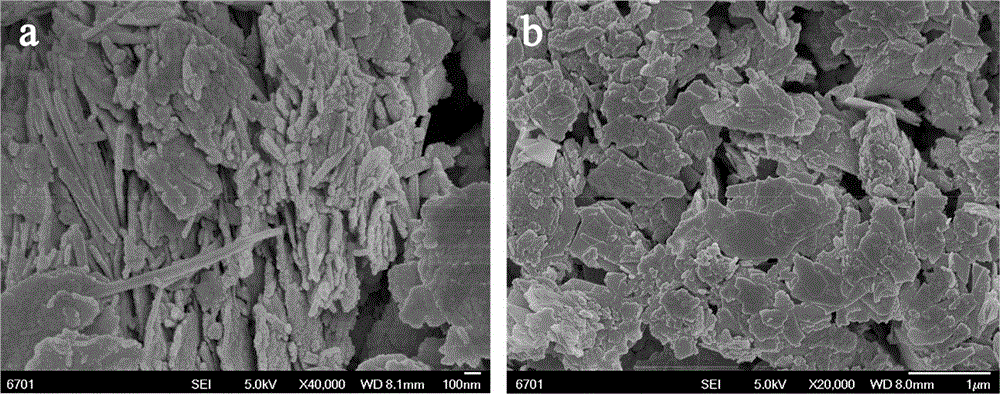

Method for preparing 1.1 nm tobermorite from low-grade attapulgite clay

A technology of attapulgite clay and tobermullite, which is applied in the direction of aluminum silicate, silicate, nanotechnology, etc., can solve the problems of performance improvement, complicated purification process, and high cost, and achieve uniform particle size and simple preparation process , Good product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Disperse 100 g of attapulgite clay powder into 300 mL of an aqueous solution containing 50 g of sodium silicate under mechanical stirring to form a uniform suspension A; dissolve 100 g of calcium chloride in 200 mL of water to form a uniform Solution B; under stirring, slowly add solution B to suspension A to obtain a precursor suspension; then transfer the precursor suspension into a 1L hydrothermal reaction kettle, seal it, and store it at a temperature of 230°C, a pressure of 3MPa, and a pH The reaction was carried out under the condition of 14 for 5 h, and the temperature was naturally cooled to room temperature; the product was centrifuged and washed thoroughly, dried to constant weight, and ground to obtain a white 1.1 nm tobermullite powder. The product can adsorb 142.3 mg / g of Cd(II) ion, 231 mg / g of tetracycline and 192 mg / g of methylene blue.

Embodiment 2

[0020] Example 2: Disperse 10 g of attapulgite clay powder into 300 mL of an aqueous solution containing 80 g of sodium silicate under mechanical stirring to form a uniform suspension A; dissolve 100 g of calcium nitrate in 200 mL of water to form a uniform solution B; under stirring, slowly add the B solution to the suspension A to obtain the precursor suspension; then transfer the precursor suspension into a 1L hydrothermal reaction kettle, seal it, and heat it at a temperature of 140°C, a pressure of 3MPa, and a pH of 14 The reaction was carried out for 36 h under certain conditions, and the temperature was naturally lowered to room temperature; the product was centrifuged and washed thoroughly, dried to constant weight, and ground to obtain a white 1.1 nm tobermullite powder. The product can adsorb Zn(II) ion at 164.6 mg / g, tetracycline at 243 mg / g, and methylene blue at 216 mg / g.

Embodiment 3

[0021] Example 3: Disperse 50 g of attapulgite clay powder into 300 mL of an aqueous solution containing 50 g of sodium potassium silicate under mechanical stirring to form a uniform suspension A; disperse 100 g of calcium bicarbonate in 200 mL of water to form Homogeneous solution B; under stirring, slowly add solution B to suspension A to obtain a precursor suspension; then transfer the precursor suspension into a 1L hydrothermal reaction kettle, seal it, and store it at a temperature of 230°C and a pressure of 3MPa. The reaction was carried out at pH 10 for 24 hours, and the temperature was naturally cooled to room temperature; the product was centrifuged and washed thoroughly, dried to constant weight, and ground to obtain a white 1.1 nm tobermullite powder. The product can adsorb Cu(II) ions at 186.3 mg / g, tetracycline at 226 mg / g, and methylene blue at 246 mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com