Method for producing cabinet board by adopting damp-proof composite urea resin

A technology of urea-formaldehyde resin and urea-formaldehyde resin glue, which is applied in the field of producing cabinet boards with moisture-proof composite urea-formaldehyde resin, can solve problems such as reduction, and achieve the effects of simple process, full use of resources, and reduction of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

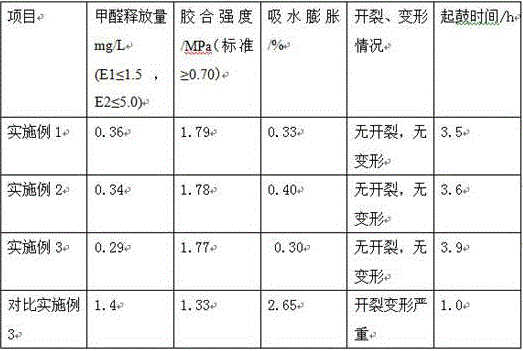

Examples

Embodiment 1

[0065] A method for producing cabinet boards by using moisture-proof composite urea-formaldehyde resin. The cabinet boards have the following structure from top to bottom: decorative paper, fir veneer, particle board, and back board; the cabinet boards are edged with aluminum alloy; fir veneer and particle board The moisture-proof composite urea-formaldehyde resin adhesive is applied between the particle board and the backboard, and the moisture-proof composite urea-formaldehyde resin adhesive is applied between the particleboard and the backboard, and the moisture-proof composite urea-formaldehyde resin adhesive is also used for the particleboard in the cabinet board; , Chinese fir veneer and backboard are respectively glued and covered with particleboard and decorated.

[0066] The preparation process of described particle board is:

[0067] 1) After simple screening, the waste materials that cannot be used in the process of making multi-layer eucalyptus boards after rotary ...

Embodiment 2

[0095] A method for producing cabinet boards by using moisture-proof composite urea-formaldehyde resin. The cabinet boards have the following structure from top to bottom: decorative paper, fir veneer, particle board, and back board; the cabinet boards are edged with aluminum alloy; fir veneer and particle board The moisture-proof composite urea-formaldehyde resin adhesive is applied between the particle board and the backboard, and the moisture-proof composite urea-formaldehyde resin adhesive is applied between the particleboard and the backboard, and the moisture-proof composite urea-formaldehyde resin adhesive is also used for the particleboard in the cabinet board; , Chinese fir veneer and backboard are respectively glued and covered with particleboard and decorated.

[0096] The preparation process of described particle board is:

[0097] 1) After simple screening, the waste materials that cannot be used in the process of making multi-layer eucalyptus boards after rotary ...

Embodiment 3

[0125] A method for producing cabinet boards by using moisture-proof composite urea-formaldehyde resin. The cabinet boards have the following structure from top to bottom: decorative paper, fir veneer, particle board, and back board; the cabinet boards are edged with aluminum alloy; fir veneer and particle board The moisture-proof composite urea-formaldehyde resin adhesive is applied between the particle board and the backboard, and the moisture-proof composite urea-formaldehyde resin adhesive is applied between the particleboard and the backboard, and the moisture-proof composite urea-formaldehyde resin adhesive is also used for the particleboard in the cabinet board; , Chinese fir veneer and backboard are respectively glued and covered with particleboard and decorated.

[0126] The preparation process of described particle board is:

[0127] 1) After simple screening, the waste materials that cannot be used in the process of making multi-layer eucalyptus boards after rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com