Continuous production line automatic foam cutting method capable of improving production efficiency and cutting precision

A technology of production efficiency and automatic cutting, which is applied in metal processing and other directions, can solve the problems of excessive labor, high labor intensity, and low production capacity, and achieve the effects of reducing product costs, accurate and reliable equipment operation, and high material cutting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

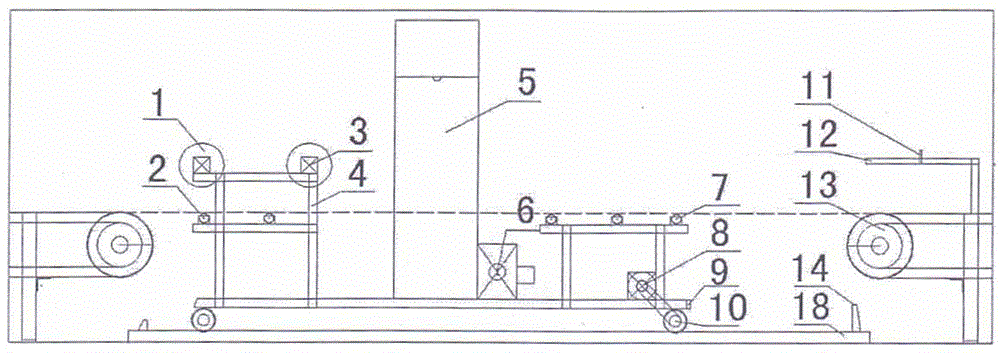

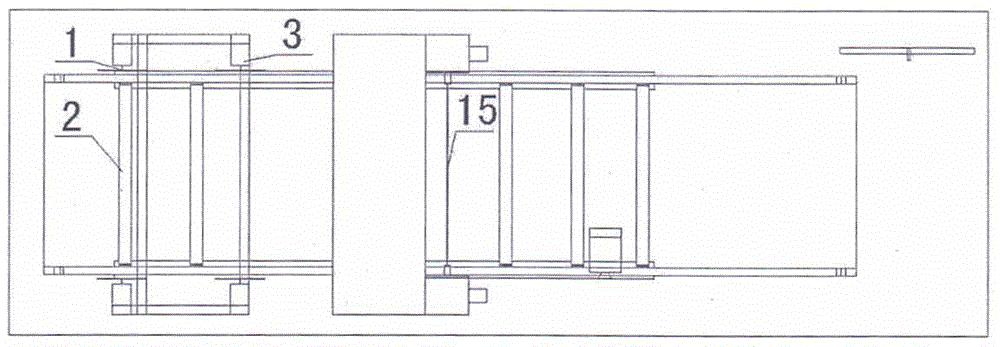

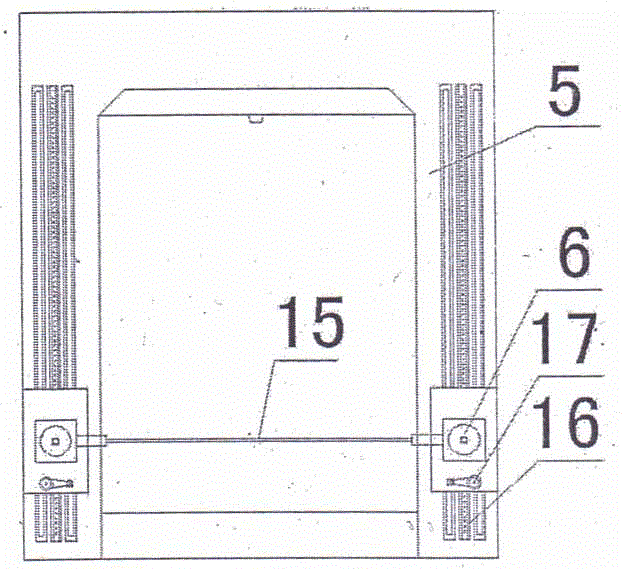

[0025] Such as Figure 1 to Figure 3 As shown, the structure diagram of the foam automatic cutting device of the continuous production line according to the embodiment of the present invention, its structure mainly includes: clamping dial 1, guide roller 2, pneumatic actuator 3, bracket 4, gantry frame 5, vibrating head 6. Guide roller 7, motor 8, limit switch 9, roller 10, cross bar 11, induction device 12, fast conveyor belt 13, baffle plate 14, cutter 15, slide rail 16, machine head driver 17 and guide rail 18 .

[0026] An automatic foam cutting device for a continuous production line, including a base that can move on a guide rail; a clamping and protecting device is installed on the base, which is used for guiding, limiting, clamping and straightening the foam delivered from the previous production line; a cutting device is installed on the base and behind the clamping and protecting device The device is used to cut the solidified and formed foam produced by the continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com