A counterweight system for a magnetic levitation machining center

A machining center and magnetic levitation technology, which is applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of inability to meet the application needs of ultra-high precision, falling of the counterweight balance machine head, and short service life, etc. , to achieve the effect of simple structure, precise control and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

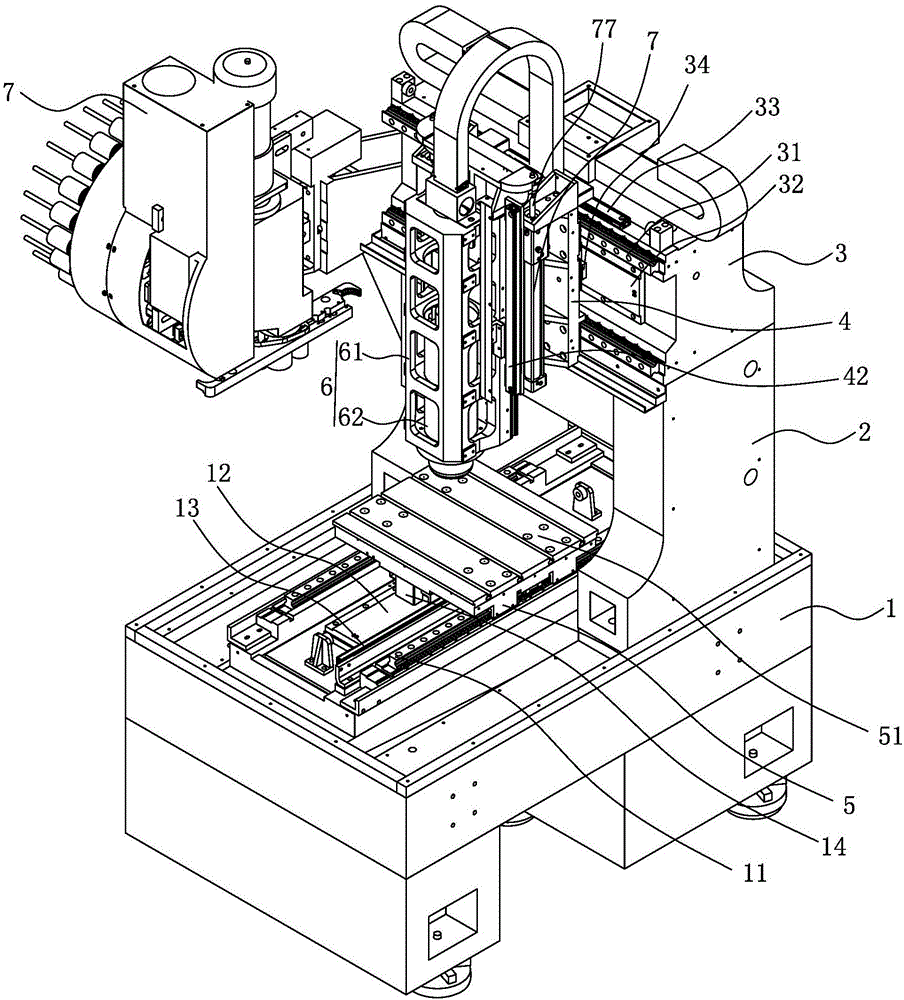

[0023] Such as Figure 1 to Figure 6 As shown, the maglev gantry machining center includes a base 1, two uprights 2 arranged at intervals on the base 1, a crossbeam 3 arranged between the two uprights 2, a tool magazine 7 arranged on one side of the crossbeam 3, and a ground movable horizontally and horizontally. The first sliding seat 4 arranged on the crossbeam 3, the second sliding seat 5 arranged on the base 1 that can move vertically and horizontally, the machine head mounting frame 63 that can be moved up and down on the first sliding seat 4, and installed on the The machine head 6 on the machine head mounting frame 63, the object stage 51 that is rotatably arranged on the second slide seat 5, is arranged between the second slide seat 5 and the object stage 51 for driving the object stage 51 to rotate The first DD motor, the X-axis moving mechanism arranged between the beam 3 and the first sliding seat 4, the Y-axis moving mechanism arranged between the base 1 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com