High-stability sertraline hydrochloride capsule and preparation method thereof

A technology of sertraline hydrochloride and high stability, which is applied in the field of high stability sertraline hydrochloride capsules and its preparation, and can solve the problems of poor chemical stability of preparations and failure to obtain better breakthroughs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

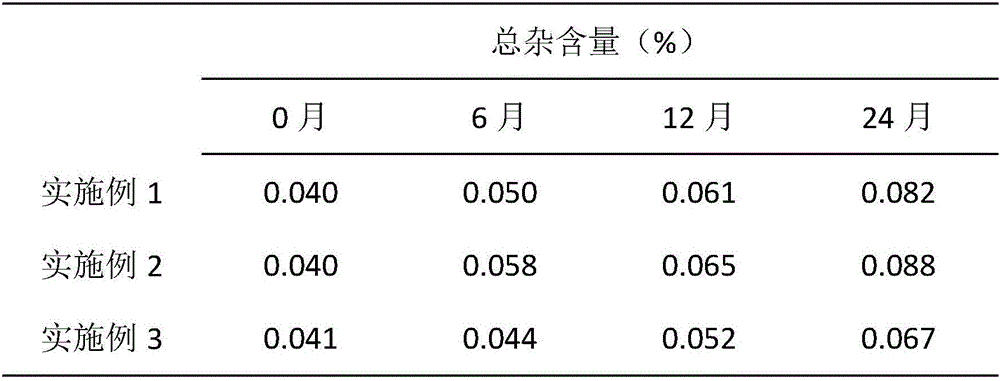

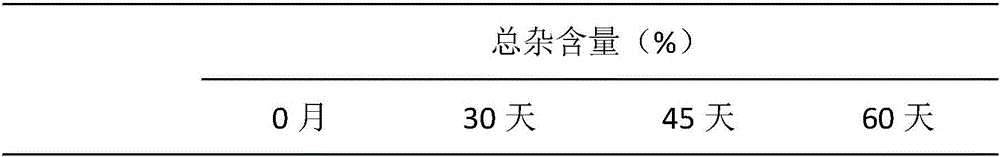

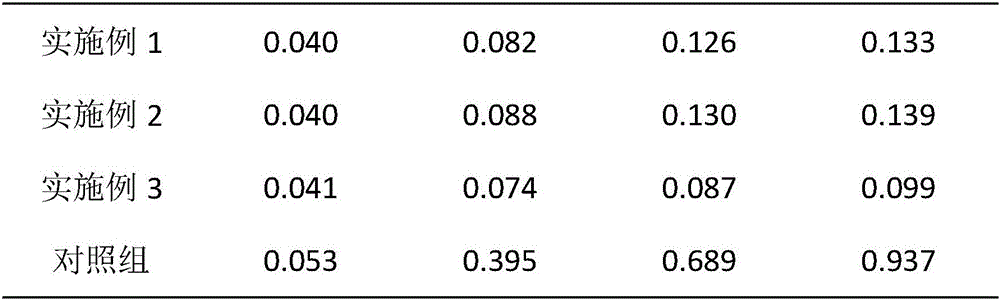

Examples

Embodiment 1

[0022] (1) In parts by weight, 20 parts of sertraline hydrochloride, 30 parts of lactose, 25 parts of microcrystalline cellulose, 20 parts of low-substituted hydroxypropyl cellulose and 5 parts of mannitol are mixed;

[0023] (2) Add ethanol (75% mass fraction) to step (1) gain, make soft material, cross 20 mesh sieves and granulate;

[0024] (3) drying the product obtained in step (2) at an environment of 65-75°C; then passing through a 20-mesh sieve for sizing;

[0025] (4) Put the product obtained in step (3) into a hard gelatin capsule shell to obtain the product.

Embodiment 2

[0027] (1) In parts by weight, 25 parts of sertraline hydrochloride, 38 parts of lactose, 30 parts of microcrystalline cellulose, 22 parts of low-substituted hydroxypropyl cellulose and 10 parts of mannitol are mixed;

[0028] (2) Add ethanol (75% mass fraction) to step (1) gain, make soft material, cross 20 mesh sieves and granulate;

[0029] (3) drying the product obtained in step (2) at an environment of 65-75°C; then passing through a 20-mesh sieve for sizing;

[0030] (4) Put the product obtained in step (3) into a hard gelatin capsule shell to obtain the product.

Embodiment 3

[0032] (1) In parts by weight, 22 parts of sertraline hydrochloride, 35 parts of lactose, 27 parts of microcrystalline cellulose, 21 parts of low-substituted hydroxypropyl cellulose and 7 parts of mannitol are mixed;

[0033] (2) Add ethanol (75% mass fraction) to step (1) gain, make soft material, cross 20 mesh sieves and granulate;

[0034] (3) drying the product obtained in step (2) at an environment of 65-75°C; then passing through a 20-mesh sieve for sizing;

[0035] (4) Put the product obtained in step (3) into a hard gelatin capsule shell to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com