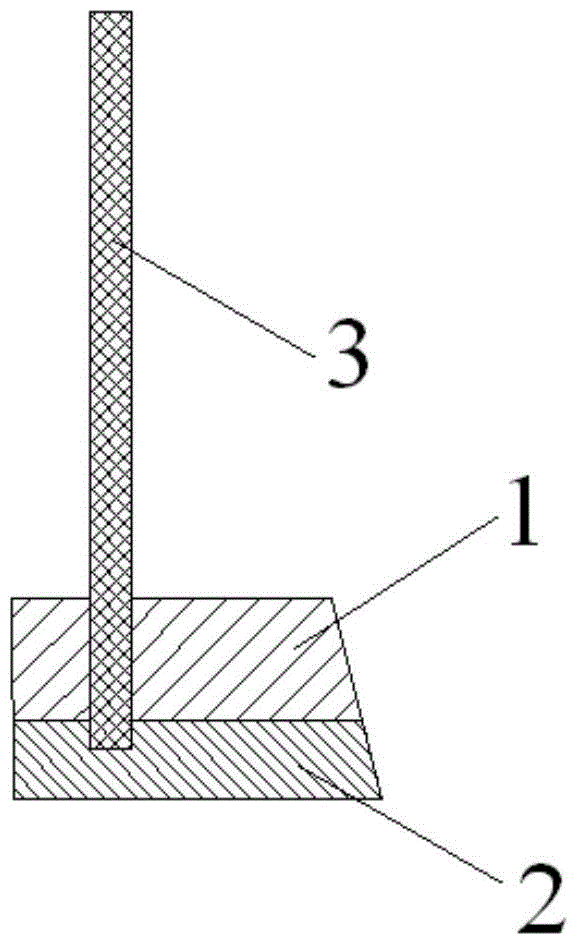

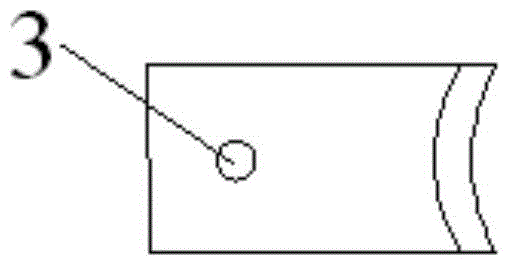

Preparation method of trapezoidal carbon brush for seat motor

A carbon brush and trapezoidal technology is applied in the field of preparation of carbon brushes for seat motors, which can solve problems such as the inability of noise performance to meet user requirements, and achieve the effects of low noise, good lubricating performance and good lubricating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] 1. Prepare high conductive layer mixture

[0080] Prepare raw materials according to the weight ratio of electrolytic copper powder 50, natural graphite 50, and phenolic resin powder, then add electrolytic copper powder, natural graphite, and phenolic resin powder to the mixing equipment, stir and mix at room temperature for 50 minutes, and obtain Highly conductive layer compound.

[0081] 2. Prepare high lubricating layer mixture

[0082] (1) Preparation of lubricant

[0083] According to the proportioning by weight, natural graphite powder 45, molybdenum disulfide 48, urotropine 7, liquid phenolic resin 30 are ready raw materials, then natural graphite powder, molybdenum disulfide and urotropine are mixed evenly at normal temperature, Prepare the initial lubricant;

[0084] Heat the initial lubricant material to 90°C, then add liquid phenolic resin to it, stir and mix for 40 minutes to obtain a solid lubricant mixture;

[0085] The solid lubricant mixture is pulve...

Embodiment 2

[0095] 1. Prepare high conductive layer mixture

[0096] Prepare the raw materials according to the weight ratio of electrolytic copper powder 45, natural graphite 55, and phenolic resin powder, then add electrolytic copper powder, natural graphite, and phenolic resin powder to the mixing equipment, stir and mix at room temperature for 10 minutes, and obtain Highly conductive layer compound.

[0097] 2. Prepare high lubricating layer mixture

[0098] (1) Preparation of lubricant

[0099] According to the proportioning by weight, natural graphite powder 35, molybdenum disulfide 55, urotropine 10, liquid phenolic resin 20 prepare raw materials, then natural graphite powder, molybdenum disulfide and urotropine are mixed evenly at normal temperature, Prepare the initial lubricant;

[0100] Heat the initial lubricant material to 100°C, then add liquid phenolic resin to it, stir and mix for 60 minutes to obtain a solid lubricant mixture;

[0101] The solid lubricant mixture is p...

Embodiment 3

[0111] 1. Prepare high conductive layer mixture

[0112] According to the weight ratio of electrolytic copper powder 55, natural graphite 45, and phenolic resin powder 40, the raw materials are prepared, and then the electrolytic copper powder, natural graphite and phenolic resin powder are added to the mixing equipment, stirred and mixed at room temperature for 80 minutes, and obtained Highly conductive layer compound.

[0113] 2. Prepare high lubricating layer mixture

[0114] (1) Preparation of lubricant

[0115] According to the proportioning by weight, natural graphite powder 40, molybdenum disulfide 54, urotropine 6, liquid phenolic resin 25 are ready raw materials, then natural graphite powder, molybdenum disulfide and urotropine are mixed evenly at normal temperature, Prepare the initial lubricant;

[0116] Heat the lubricant raw material to 85°C, then add the liquid phenolic resin into it, stir and mix for 30 minutes to obtain a solid lubricant mixture;

[0117]Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com