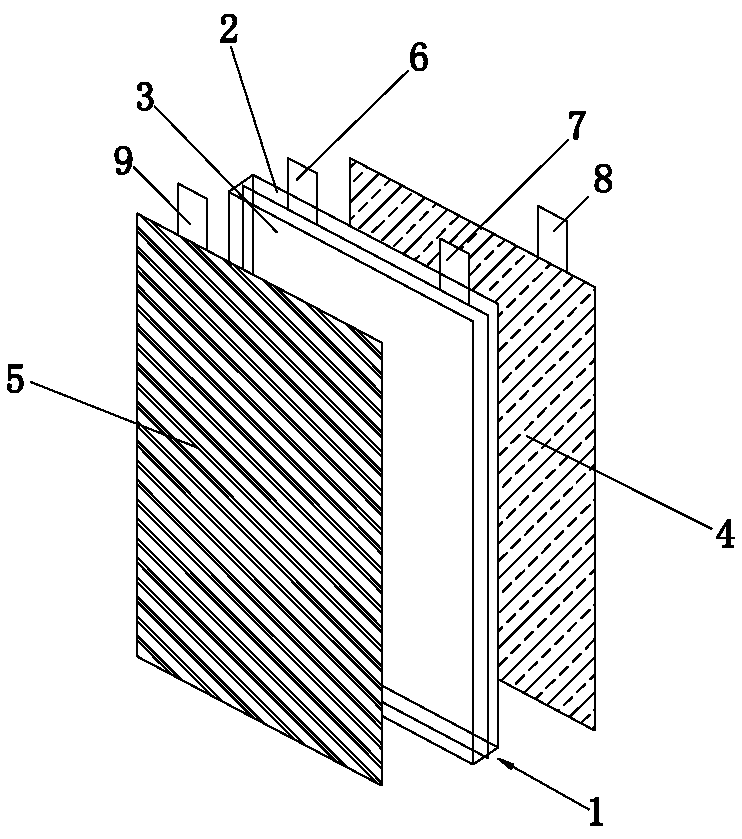

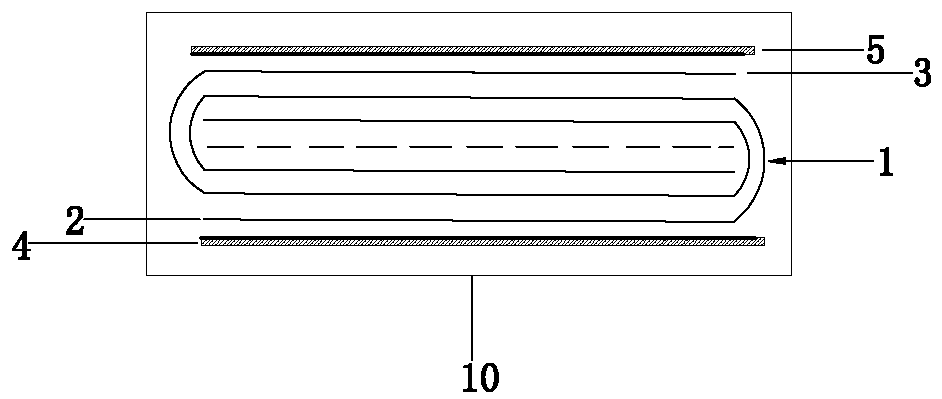

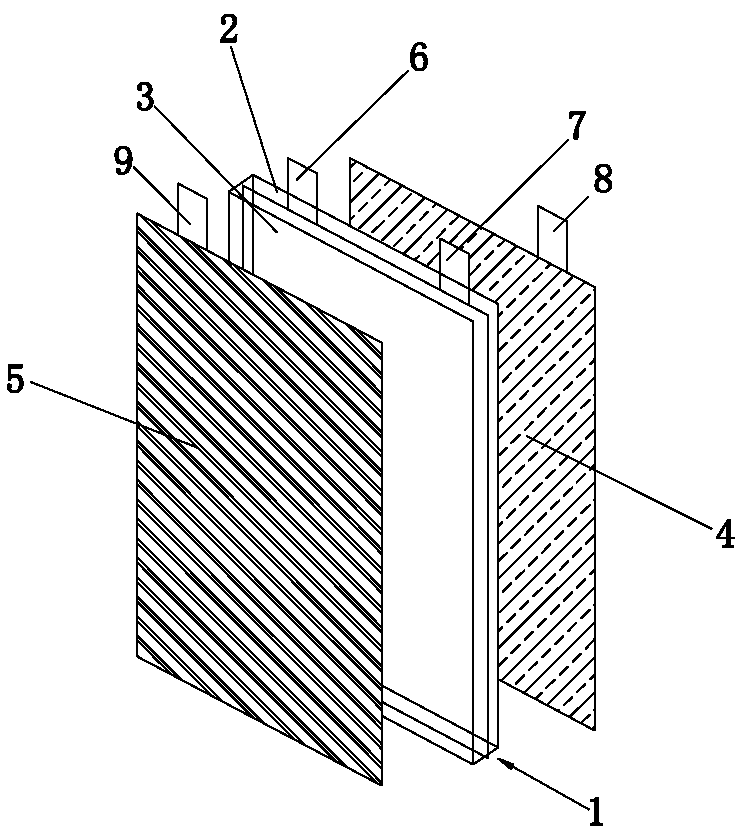

A kind of lithium ion battery and manufacturing method thereof

A lithium-ion battery, battery cathode technology, applied in circuits, electrical components, electrochemical generators, etc., can solve problems such as low rate performance and poor safety performance, improve safety performance, avoid short-circuit, and increase charge-discharge rate. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of battery positive electrode sheet: Mix nickel-cobalt lithium manganese oxide, conductive carbon, and polyvinylidene fluoride in N-methylpyrrolidone solvent at a mass ratio of 96:2:2 to make positive electrode slurry, and then coat it on aluminum foil After being dried, it is cold-pressed and slitting to make the positive electrode sheet of the battery.

[0035] Preparation of battery negative electrode sheet: Mix graphite, conductive carbon, sodium carboxymethyl cellulose, and styrene-butadiene rubber in deionized water at a mass ratio of 96:1.5:1.5:1 to make negative electrode slurry, and then coat it on copper foil After drying, cold pressing and slitting are carried out to make battery negative plates.

[0036] Preparation of isolation membrane: the isolation membrane is a 12 μm polyethylene / polypropylene composite microporous film.

[0037] Electrolyte preparation: Lithium hexafluorophosphate was dissolved in a mixed solvent composed of ethylene carbo...

Embodiment 2

[0040] The difference from Example 1 is that the production of lithium-ion batteries: Step 1: select a metal aluminum sheet of 5 mm, and lead out the positive electrode conductive terminal by welding or cutting; select a metal copper sheet of 5 mm, and lead out the negative electrode by welding or cutting Conductive terminal; Step 2: Coating polyethylene PE material on the outer surface of the metal aluminum sheet and the metal copper sheet respectively to form the positive electrode sheet and the negative electrode sheet of the capacitor, and ensure that the surface after the coating treatment is smooth and smooth, so as to increase the flatness of the battery ; Step 3: After laminating the above-mentioned battery positive electrode sheet, separator, and battery negative electrode sheet sequentially, the battery cell is made by stacking sheets, and the outermost layer of the battery cell is respectively left with a battery positive electrode sheet and a battery negative electro...

Embodiment 3

[0043] The difference from Example 1 is that the production of lithium-ion batteries: Step 1: Select a 20mm metal aluminum sheet, and lead out the positive electrode conductive terminal by welding or cutting; choose a 20mm metal copper sheet, and lead out the negative electrode by welding or cutting Conductive terminal; Step 2: Cover the outer surface of the metal aluminum sheet and the metal copper sheet with polyvinyl chloride PVC material to form the positive electrode sheet of the capacitor and the negative electrode sheet of the capacitor, and ensure that the surface after the coating treatment is smooth and smooth, so as to increase the flatness of the battery Step 3: After laminating the above-mentioned battery positive electrode sheet, separator, and battery negative electrode sheet sequentially, the battery cell is made by stacking sheets, and the outermost layer of the battery cell is respectively left with a battery positive electrode sheet and a battery negative elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com