Lithium ion battery, cathode material thereof and preparation method

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems that hinder the practical application of micro-nano materials, pollute the environment by by-products, and complex preparation processes, and achieve low first-time efficiency improvements. , the effect of short experiment time and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

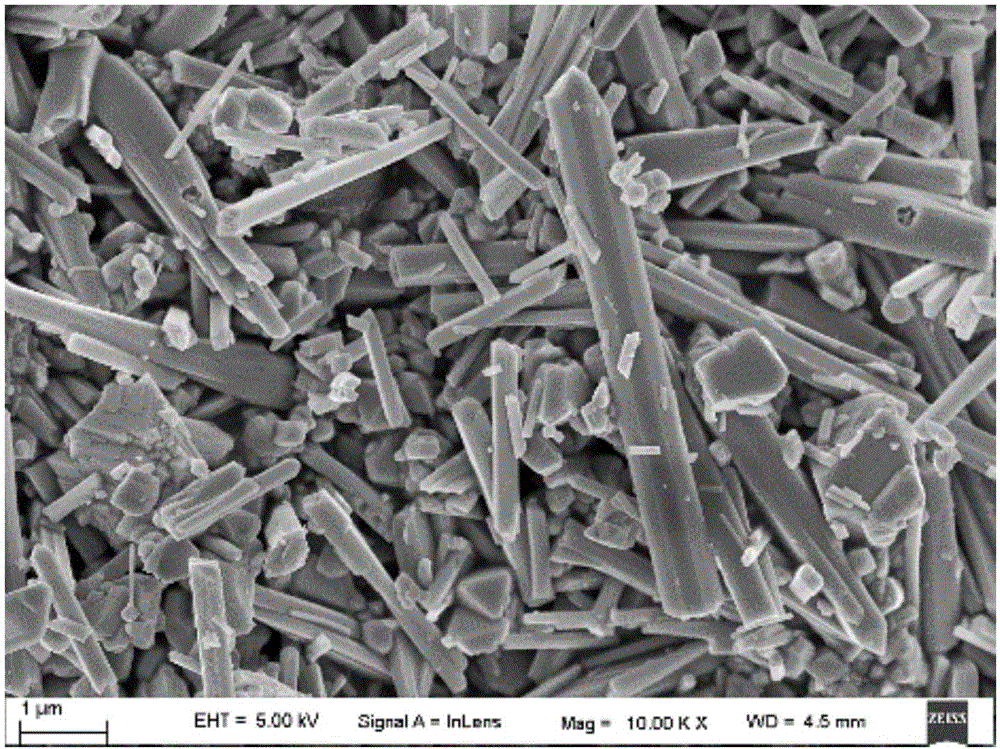

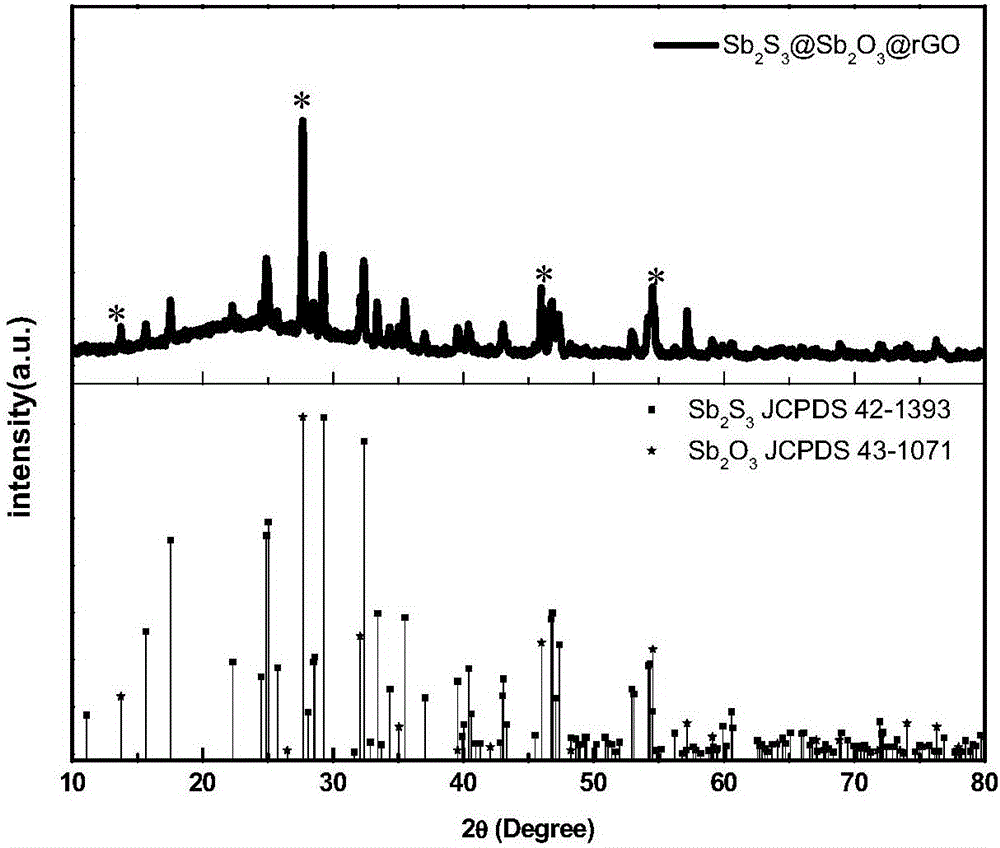

[0039] This embodiment provides a negative electrode material for a lithium ion battery, the negative electrode material has a core-shell structure comprising a core layer and a shell layer; the core layer is antimony trioxide, the shell layer is antimony trisulfide, the core layer and the shell layer The mass ratio of the core layer is 1.43:1, the particle size of the core layer is 100nm-2μm, the thickness of the shell layer is 50nm-0.5μm, the microscopic shape of the core layer is rod-shaped, and its specific surface area is 217m 2 g -1 .

[0040] Its preparation method comprises the following steps:

[0041] In the first step, at room temperature, put 0.25g SbCl 3 Add it into 30mL deionized water, sonicate for 3min, magnetically stir for 20min, add 30mL of ethylene glycol, sonicate for 3min, magnetically stir for 20min, transfer to a hydrothermal kettle, keep warm at 160°C for 10h, and use deionized water and absolute ethanol alternately Centrifuge and wash three times a...

Embodiment 2

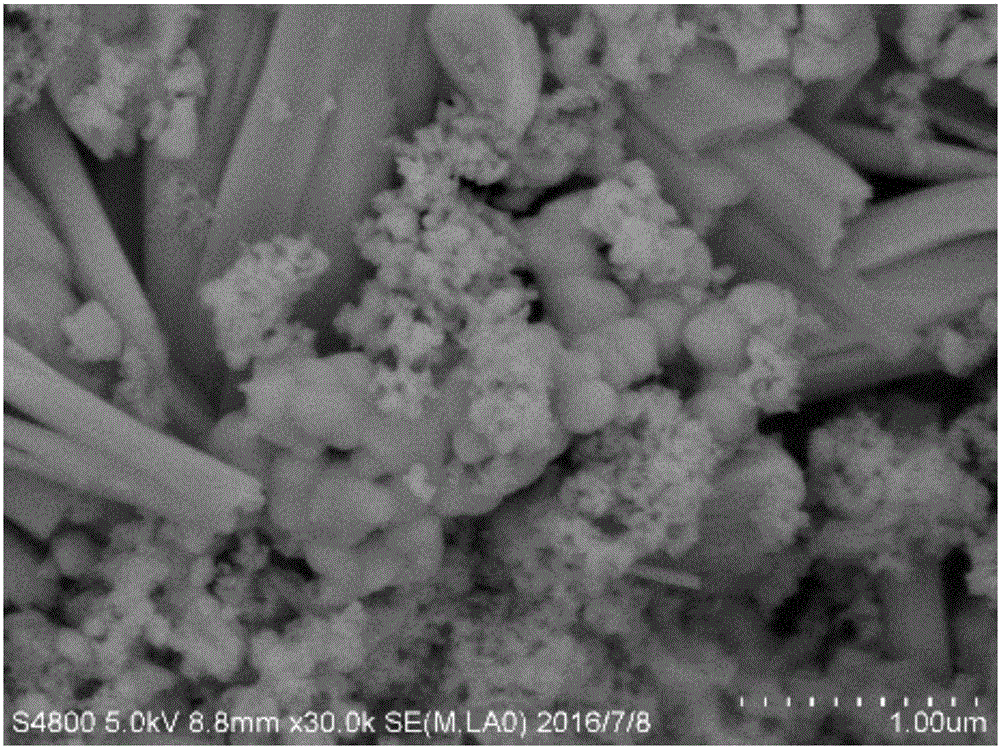

[0046] This embodiment provides a negative electrode material for a lithium ion battery, the negative electrode material has a core-shell structure comprising a core layer and a shell layer; the core layer is antimony trioxide, the shell layer is antimony trisulfide, the core layer and the shell layer The mass ratio of the core layer is 1.43:1, the particle size of the core layer is 100nm-2μm, the thickness of the shell layer is 50nm-0.5μm, the microscopic shape of the core layer is spherical, and its specific surface area is 370m 2 g -1 .

[0047] Its preparation method comprises the following steps:

[0048] In the first step, at room temperature, put 0.25g SbCl 3 Add it into 30mL deionized water, sonicate for 3min, magnetically stir for 20min, add 30mL of ethylene glycol, sonicate for 3min, magnetically stir for 20min, transfer to a hydrothermal kettle, keep warm at 160°C for 10h, and use deionized water and absolute ethanol alternately Centrifuge and wash three times at...

Embodiment 3

[0052] This embodiment provides a negative electrode material for a lithium ion battery, the negative electrode material has a core-shell structure comprising a core layer and a shell layer; the core layer is antimony trioxide, the shell layer is antimony trisulfide, the core layer and the shell layer The mass ratio of the core layer is 1.43:1, the particle size of the core layer is 100nm-2μm, the thickness of the shell layer is 50nm-0.5μm, the microscopic shape of the core layer is sea urchin-like, and its specific surface area is 457m 2 g -1 .

[0053] Its preparation method comprises the following steps:

[0054] In the first step, at room temperature, put 0.25g SbCl 3 Add it into 30mL deionized water, sonicate for 3min, magnetically stir for 20min, add 30mL of ethylene glycol, sonicate for 3min, magnetically stir for 20min, transfer to a hydrothermal kettle, keep warm at 160°C for 10h, and use deionized water and absolute ethanol alternately Centrifuge and wash three ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com