A method for preparing doped perovskite thin film batteries by dissolving lead iodide at room temperature

A thin film battery, perovskite technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of restricted application, low repeatability, poor stability, etc., to improve stability, improve solubility, and improve battery conversion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

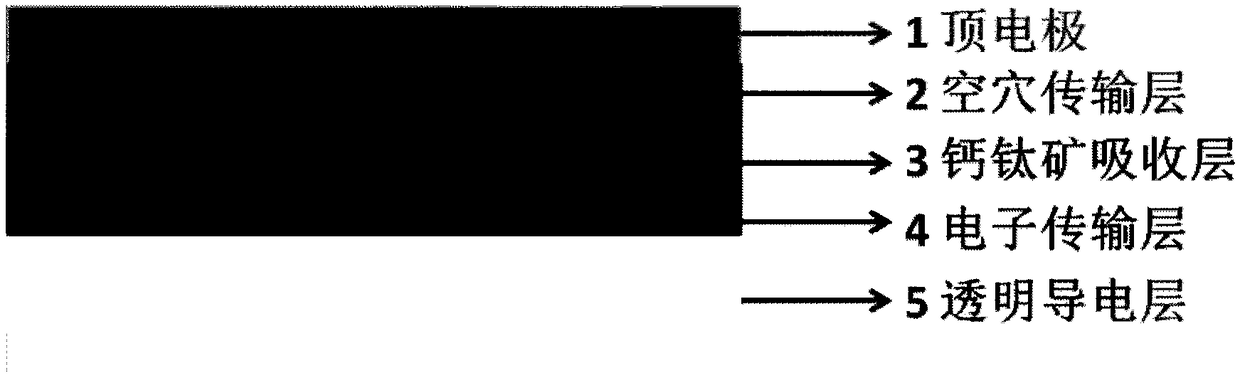

[0031] In this embodiment, the method for dissolving lead iodide at room temperature to prepare a doped perovskite thin film battery is as follows:

[0032] 1. Ultrasonic cleaning the substrate with detergent, acetone, absolute ethanol, and deionized water in sequence, and then drying the substrate with nitrogen; the substrate is FTO transparent conductive glass, and its square resistance is ~15Ω / sq;

[0033] 2. Spin-coat isopropoxy titanic acidic solution on the substrate treated in step 1, sinter in air at 450°C for 30min, and then soak in 40mM TiCl 4 solution, treated at 70°C for 30 minutes, and finally sintered at 450°C for 30 minutes to obtain a dense electron transport layer TiO 2 film.

[0034] The preparation process of the isopropoxytitanium acidic solution is as follows: 730 μL of isopropoxytitanium (Ti{OCH(CH 3 ) 2} 4) was added to 5 mL of ethanol to obtain solution A, 69 μL of 2M HCl was added to 5 mL of ethanol to obtain solution B, and solution A and solution...

Embodiment 2

[0039] 1. Ultrasonic cleaning the substrate with detergent, acetone, absolute ethanol, and deionized water in sequence, and then drying the substrate with nitrogen; the substrate is FTO transparent conductive glass, and its square resistance is ~15Ω / sq;

[0040] 2. Spin-coat isopropoxy titanic acidic solution on the substrate treated in step 1, sinter in air at 450°C for 30min, and then soak in 40mM TiCl 4 solution, treated at 70°C for 30 minutes, and finally sintered at 450°C for 30 minutes to obtain a dense electron transport layer TiO 2 film.

[0041] The preparation process of the isopropoxytitanium acidic solution is as follows: 730 μL of isopropoxytitanium (Ti{OCH(CH 3 ) 2} 4 ) was added to 5 mL of ethanol to obtain solution A, 69 μL of 2M HCl was added to 5 mL of ethanol to obtain solution B, and solution A and solution B were mixed uniformly to obtain an acidic solution of isopropoxytitanium.

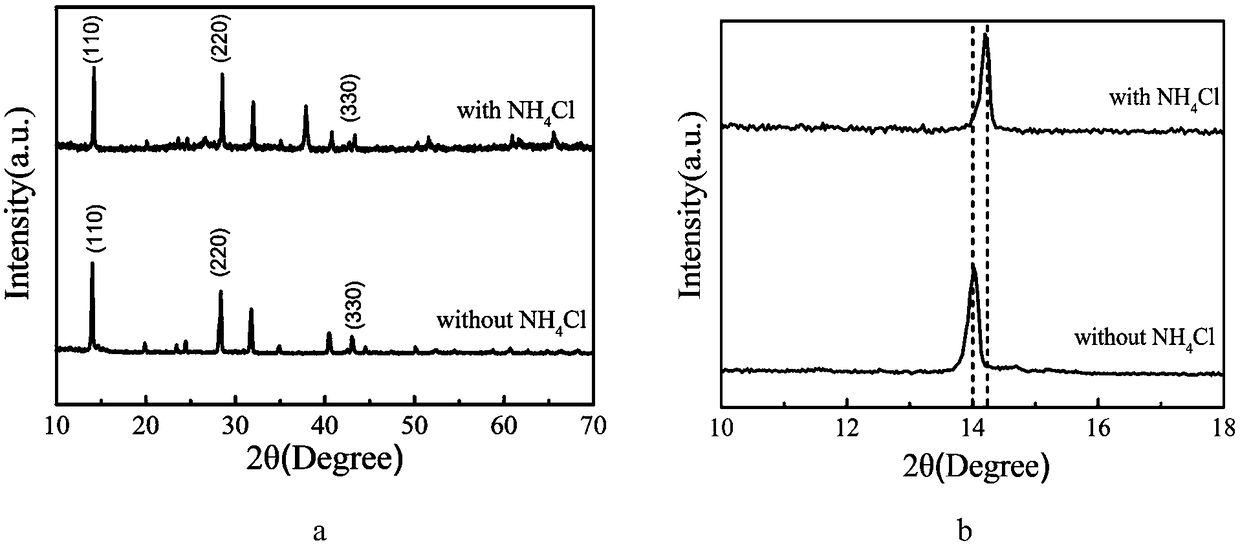

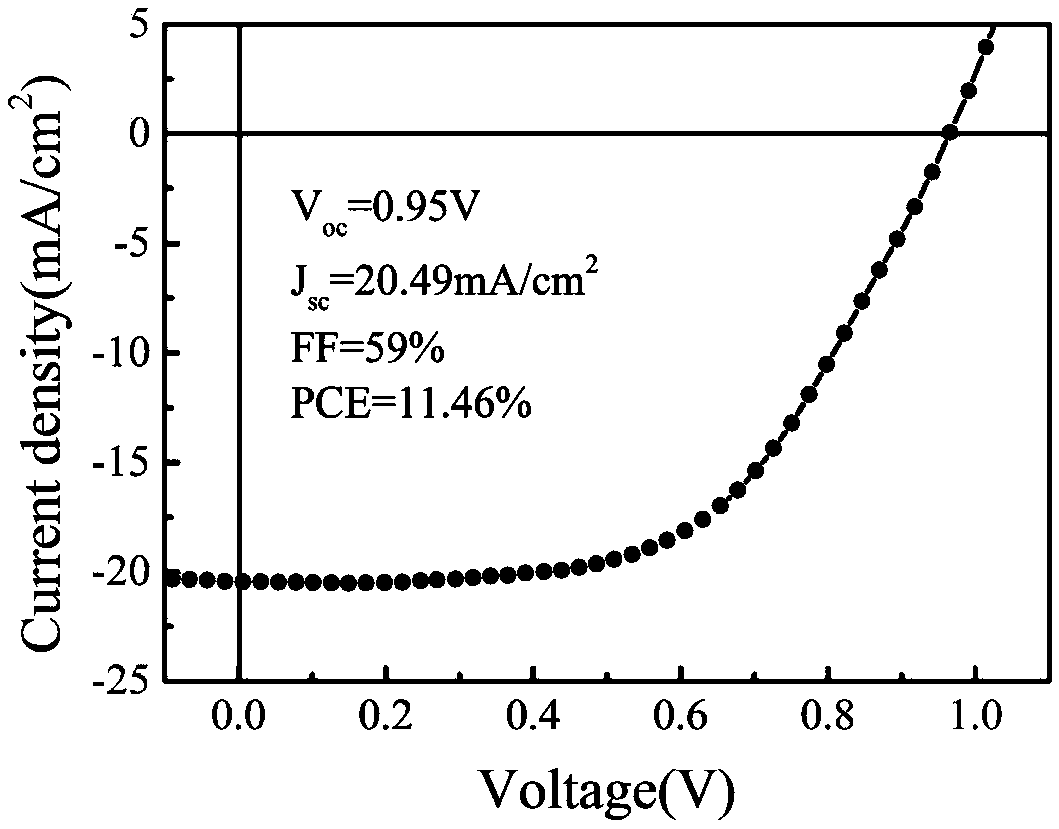

[0042] 3. Spin-coat NH on the electron transport layer 4 Cl and PbI 2...

Embodiment 3

[0047] 1. Ultrasonic cleaning the substrate with detergent, acetone, absolute ethanol, and deionized water in sequence, and then drying the substrate with nitrogen; the substrate is FTO transparent conductive glass, and its square resistance is ~15Ω / sq;

[0048] 2. Spin-coat isopropoxy titanic acidic solution on the substrate treated in step 1, sinter in air at 450°C for 30min, and then soak in 40mM TiCl 4 solution, treated at 70°C for 30 minutes, and finally sintered at 450°C for 30 minutes to obtain a dense electron transport layer TiO 2 film.

[0049] The preparation process of the isopropoxytitanium acidic solution is as follows: 730 μL of isopropoxytitanium (Ti{OCH(CH 3 ) 2} 4 ) was added to 5 mL of ethanol to obtain solution A, 69 μL of 2M HCl was added to 5 mL of ethanol to obtain solution B, and solution A and solution B were mixed uniformly to obtain an acidic solution of isopropoxytitanium.

[0050] 3. Spin-coat NH on the electron transport layer 4 Cl and PbI 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com