Preparation method and application of nitrogen-doped carbon nano tube composite L-cysteine modified glassy carbon electrode

A nanotube composite and glassy carbon electrode technology, which is applied in the direction of material analysis, measuring devices, and instruments through electromagnetic means, can solve the problems of difficult detection, unsatisfactory results of theophylline and caffeine measurement, etc., and achieve improvement Sensitivity, convenient and fast detection process, and increased current response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

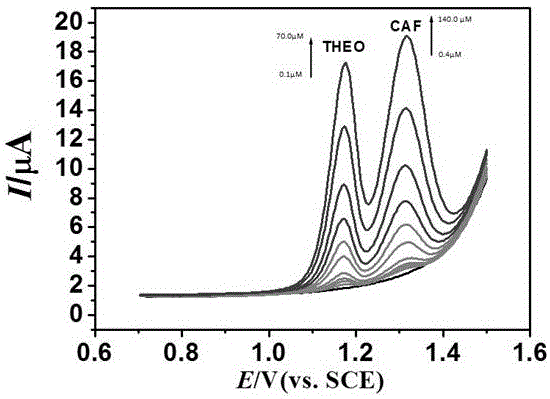

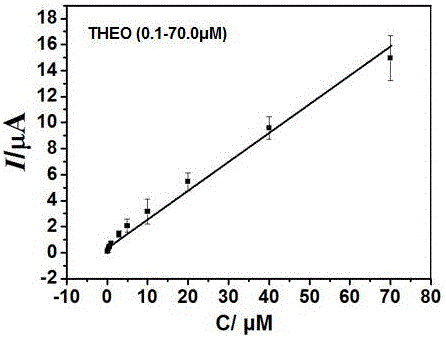

[0035] In this example, see Figure 1~4 , a method for preparing a nitrogen-doped carbon nanotube composite L-cysteine modified glassy carbon electrode, comprising the steps of:

[0036] ⅰ. Pretreatment of glassy carbon electrodes:

[0037] First, the glassy carbon electrode was coated with 0.05 μm Al 2 o 3 Polishing powder and suede are polished to a mirror surface, and then ultrasonically cleaned with distilled water, dilute nitric acid solution, absolute ethanol and double distilled water in sequence, and then used;

[0038] ⅱ. Preparation of nitrogen-doped carbon nanotube modification solution: First, take 2 mg of nitrogen-doped carbon nanotubes and dissolve them in 2 mL of ethylene glycol to prepare a suspension with a concentration of nitrogen-doped carbon nanotubes of 1 mg / mL. After the above suspension was uniform and stable, 500 μL of the dispersed suspension was added to 10 mL of KCl solution with a concentration of 0.1 mol / L by a micro-injector, and ultrasonica...

Embodiment 2

[0053] This embodiment is basically the same as Embodiment 1, especially in that:

[0054] In this embodiment, a method for preparing a nitrogen-doped carbon nanotube composite L-cysteine-modified glassy carbon electrode comprises the following steps:

[0055] ⅰ. The pretreatment of glassy carbon electrode: this step is identical with embodiment one;

[0056] First, the glassy carbon electrode was coated with 0.05 μm Al 2 o 3 Polishing powder and suede are polished to a mirror surface, and then ultrasonically cleaned with distilled water, dilute nitric acid solution, absolute ethanol and double distilled water in sequence, and then used;

[0057] ⅱ. Preparation of nitrogen-doped carbon nanotube modification solution: First, take 1.0 mg nitrogen-doped carbon nanotubes and dissolve them in 2.0 mL ethylene glycol to prepare a suspension with a nitrogen-doped carbon nanotube concentration of 0.5 mg / mL After the above suspension is uniform and stable, use a micro-injector to tak...

Embodiment 3

[0063] This embodiment is basically the same as the previous embodiment, and the special features are:

[0064] In this embodiment, a method for preparing a nitrogen-doped carbon nanotube composite L-cysteine-modified glassy carbon electrode comprises the following steps:

[0065] ⅰ. The pretreatment of glassy carbon electrode: this step is identical with embodiment one;

[0066] First, the glassy carbon electrode was coated with 0.05 μm Al 2 o 3 Polishing powder and suede are polished to a mirror surface, and then ultrasonically cleaned with distilled water, dilute nitric acid solution, absolute ethanol and double distilled water in sequence, and then used;

[0067] ⅱ. Preparation of nitrogen-doped carbon nanotube modification solution: First, take 3.0 mg nitrogen-doped carbon nanotubes and dissolve them in 2.0 mL ethylene glycol to prepare a suspension with a nitrogen-doped carbon nanotube concentration of 1.5 mg / mL After the above suspension is uniform and stable, use a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com