Pressure steel pipe reinforcement composite concrete pipe, manufactured pipe and manufacturing method

A technology for concrete pipes and pressure steel pipes, which is applied in the directions of pipes/pipe joints/fittings, pipe protection, and pipe damage/wear prevention. small gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

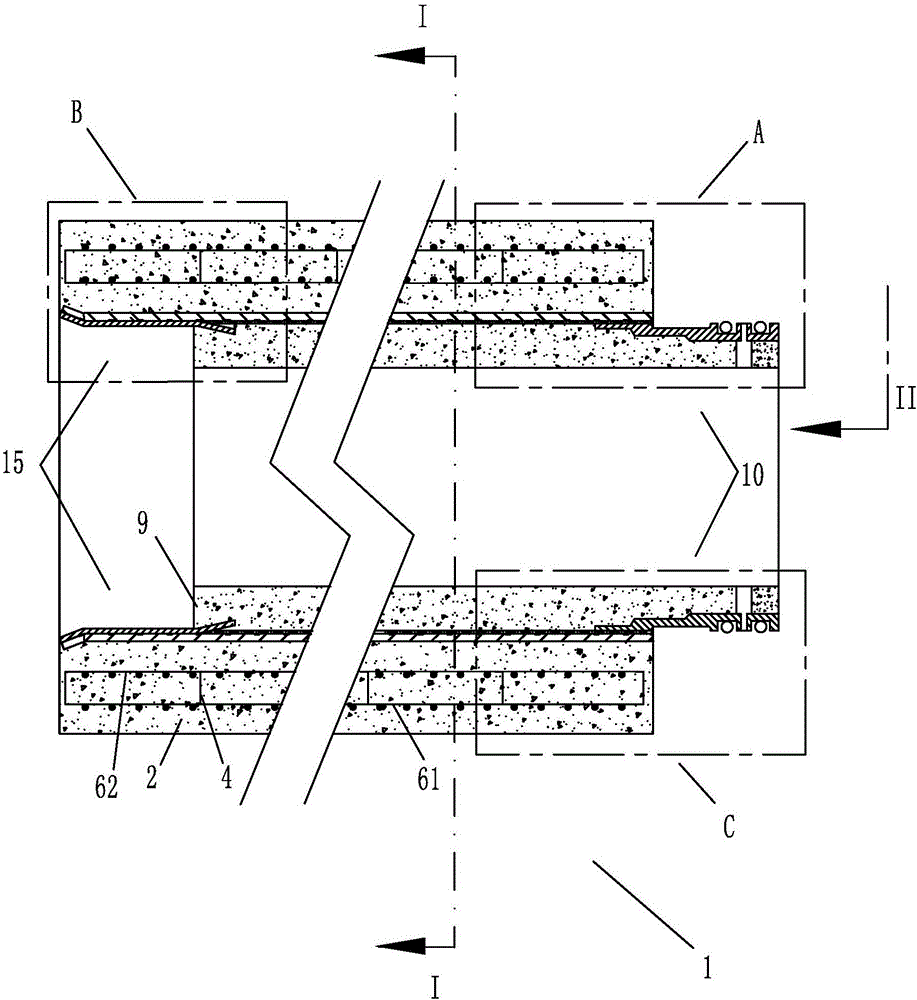

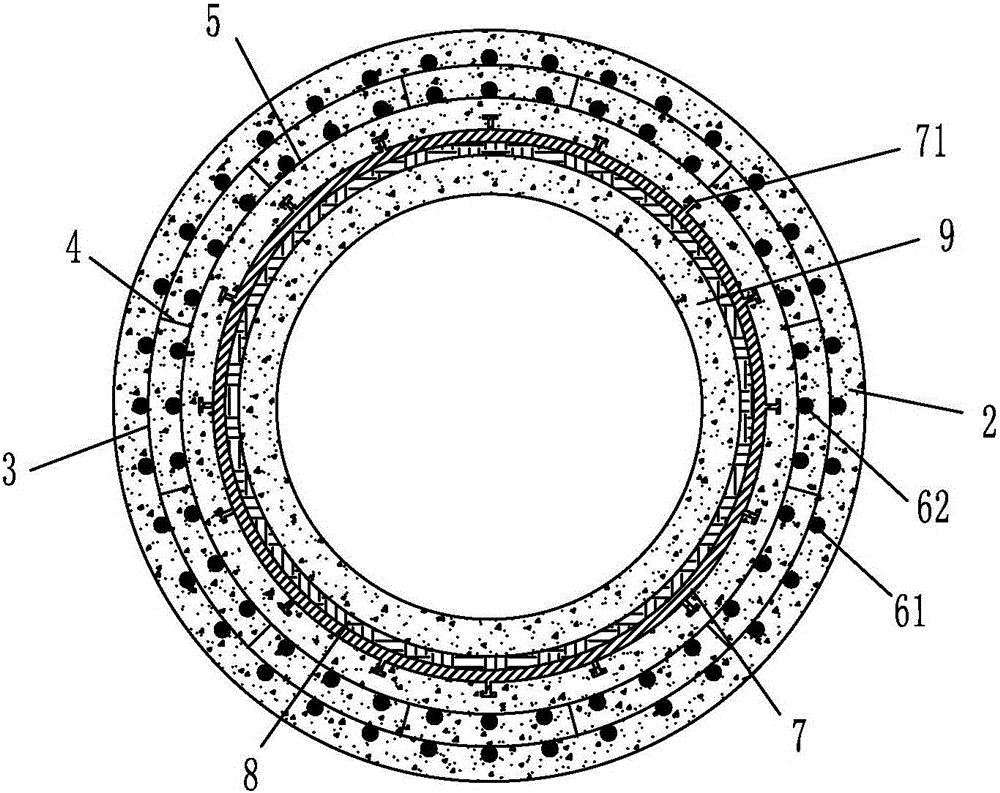

[0068] combine figure 1 , figure 2 As shown, the pipe body 1 of the penstock reinforced concrete pipe is composed of a concrete outer pipe 2, a rubber pipe 7, a steel pipe 8, and a concrete inner pipe 9 arranged in sequence from outside to inside; the concrete outer pipe 2, the rubber pipe 7, and the steel pipe 8 An outer cylinder is formed, and the outer cylinder and the concrete inner pipe 9 are staggered by a certain distance in the axial direction, wherein the protruding part of the outer cylinder forms a socket part 15 ; the protruding part of the concrete inner pipe 9 forms a socket part 10 .

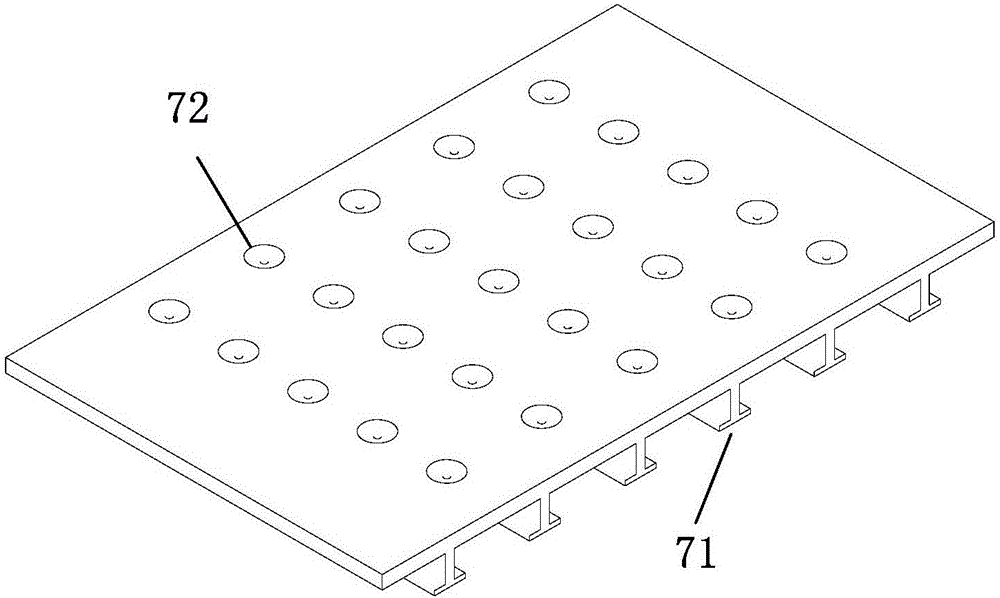

[0069] combine Figure 3 ~ Figure 6 As shown, the rubber tube 7 is made by one integral molding, and its outer surface is provided with multiple rows of T-shaped keys 71 parallel to each other, and its inner surface is provided with several soft suction cups 72 arranged in a rectangular array; the T-shaped keys 71 The row spacing is equal to that of the flexible suction cups 72...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com