Gear drive turbofan engine with reversely-mounted core machine

A turbofan engine and gear transmission technology, which is applied to machines/engines, jet propulsion devices, etc., can solve the problems of high and low pressure rotor system matching and difficulty in noise control, and achieves improved fan efficiency, simple structure, and reduced coupling vibration level. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

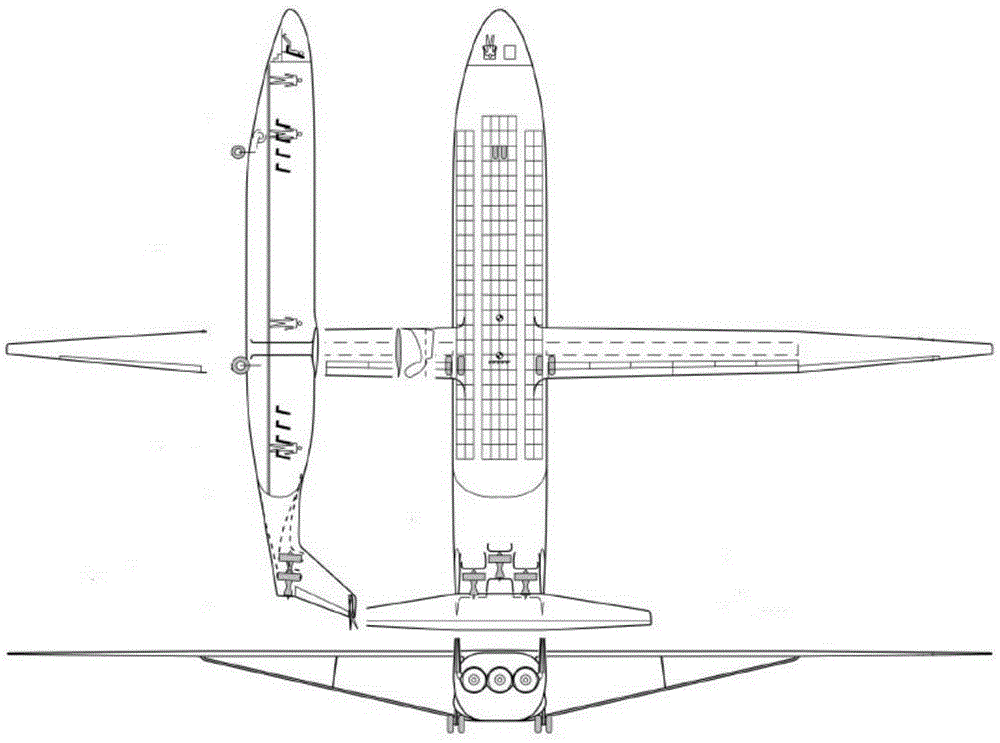

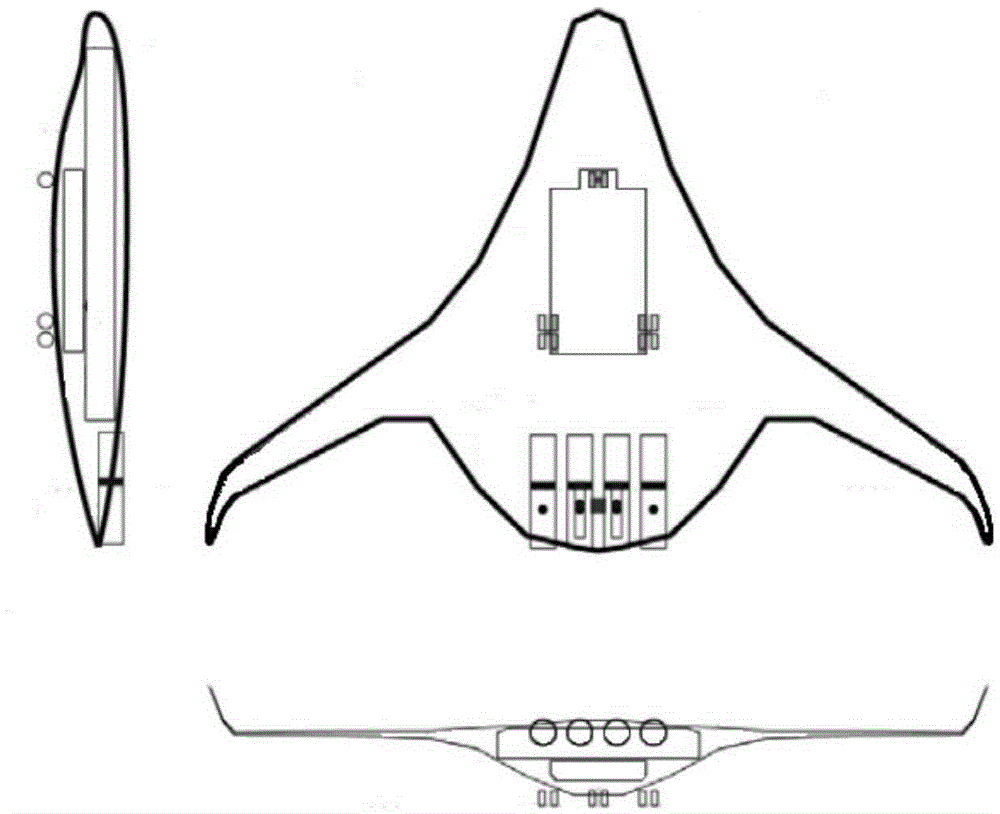

[0026] See attached picture, image 3 It is a schematic diagram of the layout of the propulsion system on the airframe. The high bypass ratio turbofan engine is arranged behind the wide and flat fuselage, and the air intake is arranged in the way of being buried in the fuselage or close to the surface of the fuselage. The engine can use the high-aspect-ratio wing to reduce drag, and the low-speed boundary layer airflow flowing through the body surface can help the engine improve propulsion efficiency and also help reduce the noise level of the whole machine.

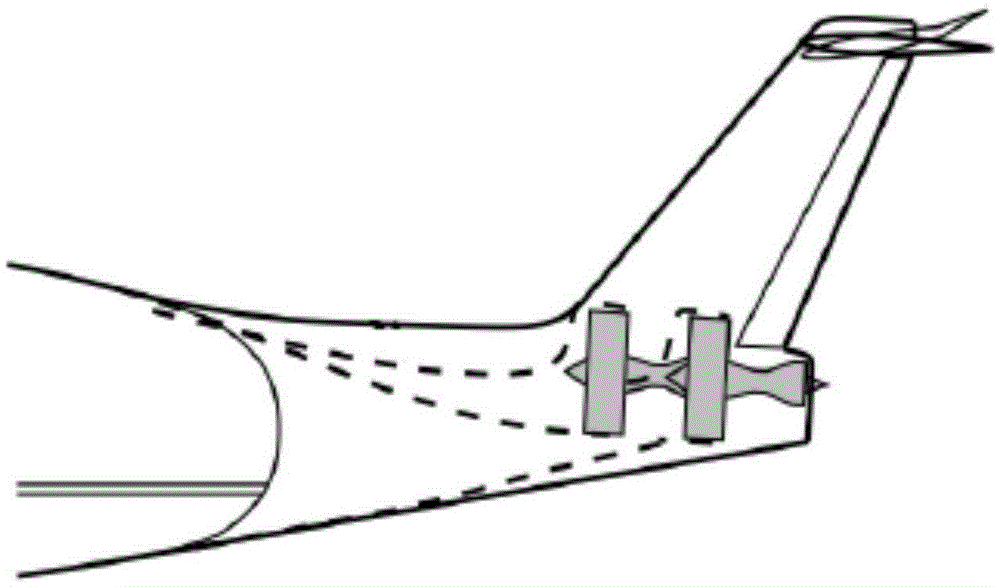

[0027] Figure 4 It is a schematic diagram of the internal structure layout of the engine and the intake and exhaust scheme. The air enters the engine through the fan 1, and after being pressurized by the fan, most of the airflow generates thrust and forms the mainstream, and a small part of the airflow passes through the outer duct 3 to the back of the core engine 4, and then enters from the opposite direction. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com