Turbine

A turbine and casing technology, applied in the field of turbines, can solve the problems of failure to achieve complete sealing effect, the energy efficiency conversion rate needs to be improved, and the complex structure of the casing, so as to achieve good sealing, reduce the difficulty of production and processing, and simplify the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings. Wherein, the descriptive terms such as up, down, left, right, etc. are used for the description, with the purpose of helping readers to understand, but not intended to limit.

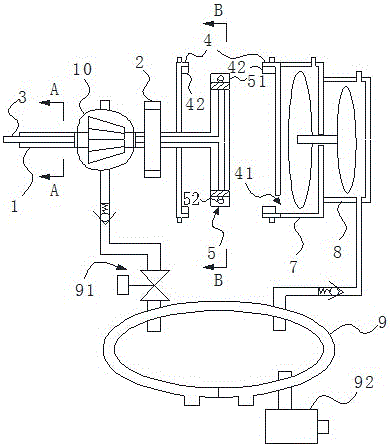

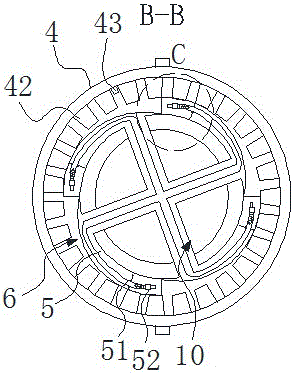

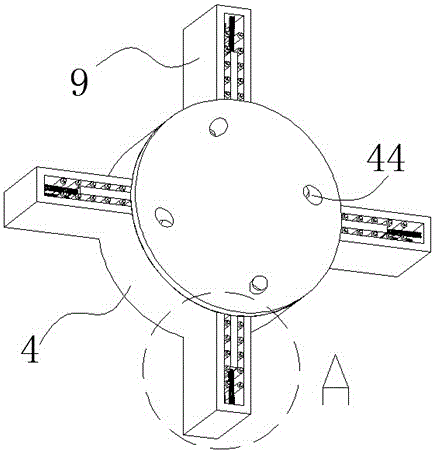

[0053] During specific implementation: if Figure 3 to Figure 10 As shown, the turbine includes a casing 4, a wheel disc 5, a wheel shaft 1 and a power take-off wheel; the casing 4 has a cylindrical inner cavity, and the outer surface of the casing 4 is provided with a row communicating with the inner cavity. Orifice 44;

[0054] The wheel 5 as a whole is coaxially and rotatably arranged in the inner cavity of the casing 4 and has a cylindrical structure with a cavity inside. Hollow gear teeth 51, each hollow gear tooth 51 is provided with a spray hole 53 on the side of each hollow gear tooth 51 (at a position away from the wheel disc 5), and the jet direction of the jet flow hole 53 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com