Multistage centrifugal pump delivery chamber

A technology of extrusion chamber and centrifugal pump, which is applied in the direction of pumps, pump components, non-variable pumps, etc., which can solve the problems of difficult casting production, unstable operation, long axial distance, etc., and reduce the difficulty of casting and production processing , Improve operational reliability, and reduce the number of runners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

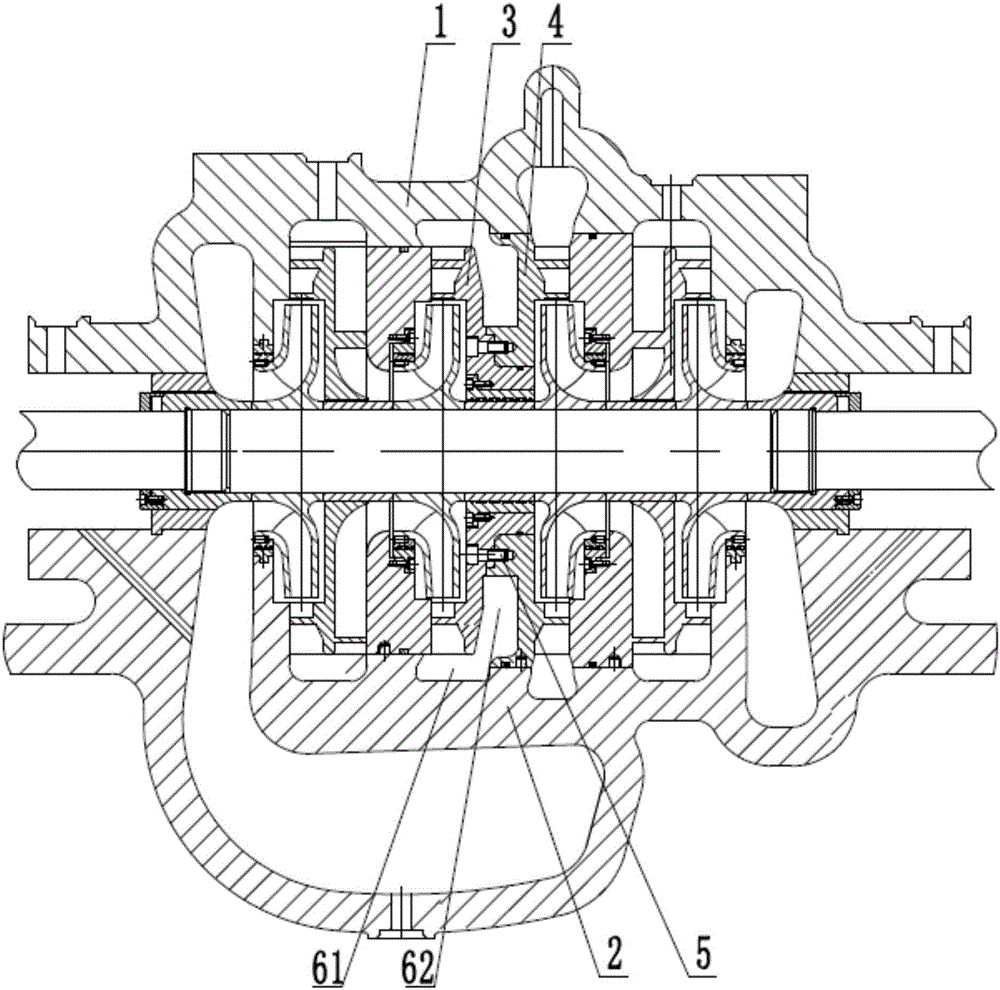

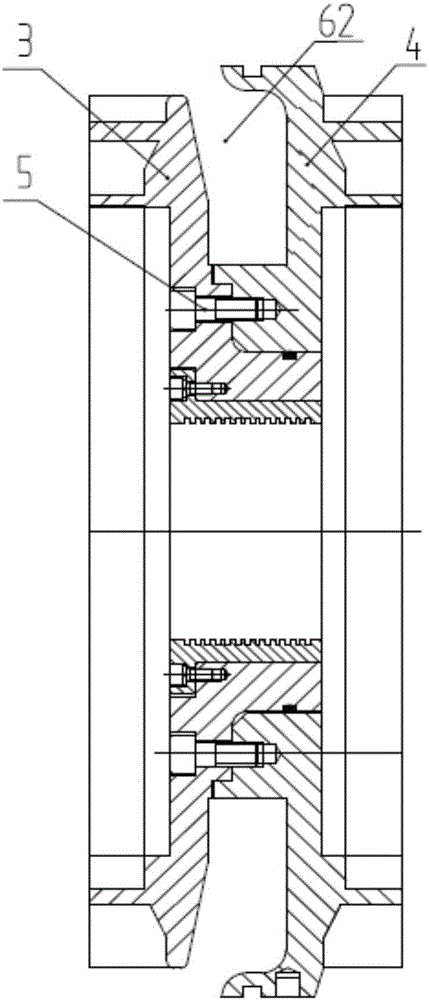

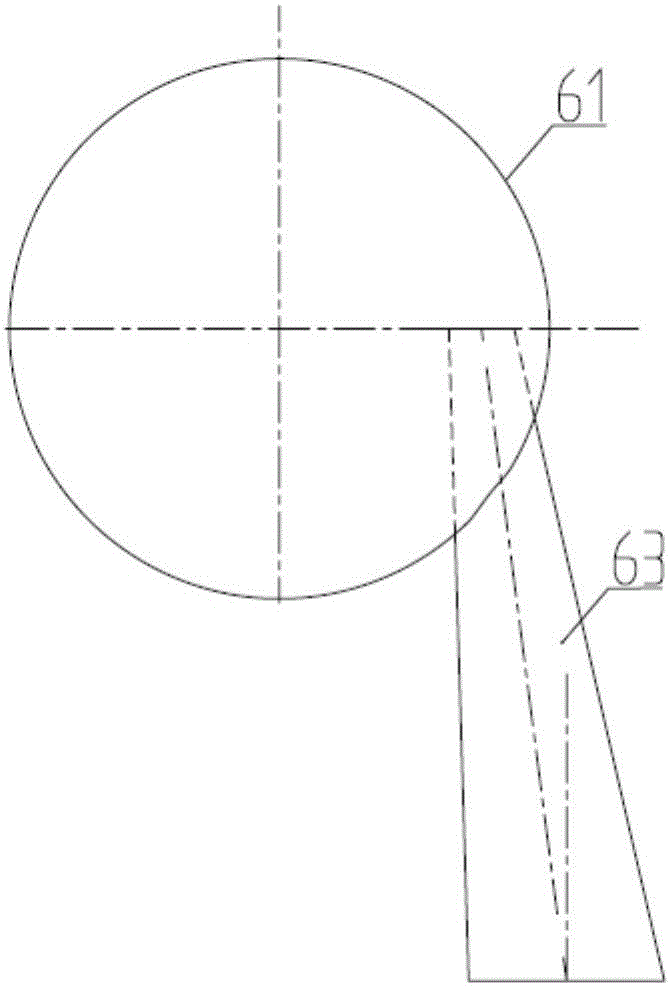

[0015] Such as figure 1 , figure 2 , image 3 The shown multi-stage centrifugal pump pressure chamber includes a first annular flow channel 62, a diffuser section 63 and a second annular flow channel 61 located outside the first annular flow channel 62, and the second annular flow channel 61 is arranged in the shell Inside the body, and located at the outlet of the first final guide vane 3, the first annular flow channel 62 is formed by the rear cover of the first final guide vane 3 and the rear cover of the second final guide vane 4 through joint fitting , the rear cover plate of the first final guide vane 3 and the rear cover plate of the second final guide vane 4 are fixedly connected by screws 5, the cross-sectional shape of the second annular flow channel 61 is rectangular; the diffuser section 63 is trumpet-shaped , located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com